方案详情

文

硬度标定法的基本原理是当某一金属材料承受一定时间、一定温度的工况过程时,其硬度与其所受的温度呈近似的线性关系。测量活塞、气缸套、气缸盖或油嘴时,将这种金属制成螺塞状或螺钉状,植入被测部件内,再通过测量工作后被测部件内该金属的硬度,与已获得的螺塞回火温度-硬度曲线进行比较,可获得该工况下被测部件的最高温度。

方案详情

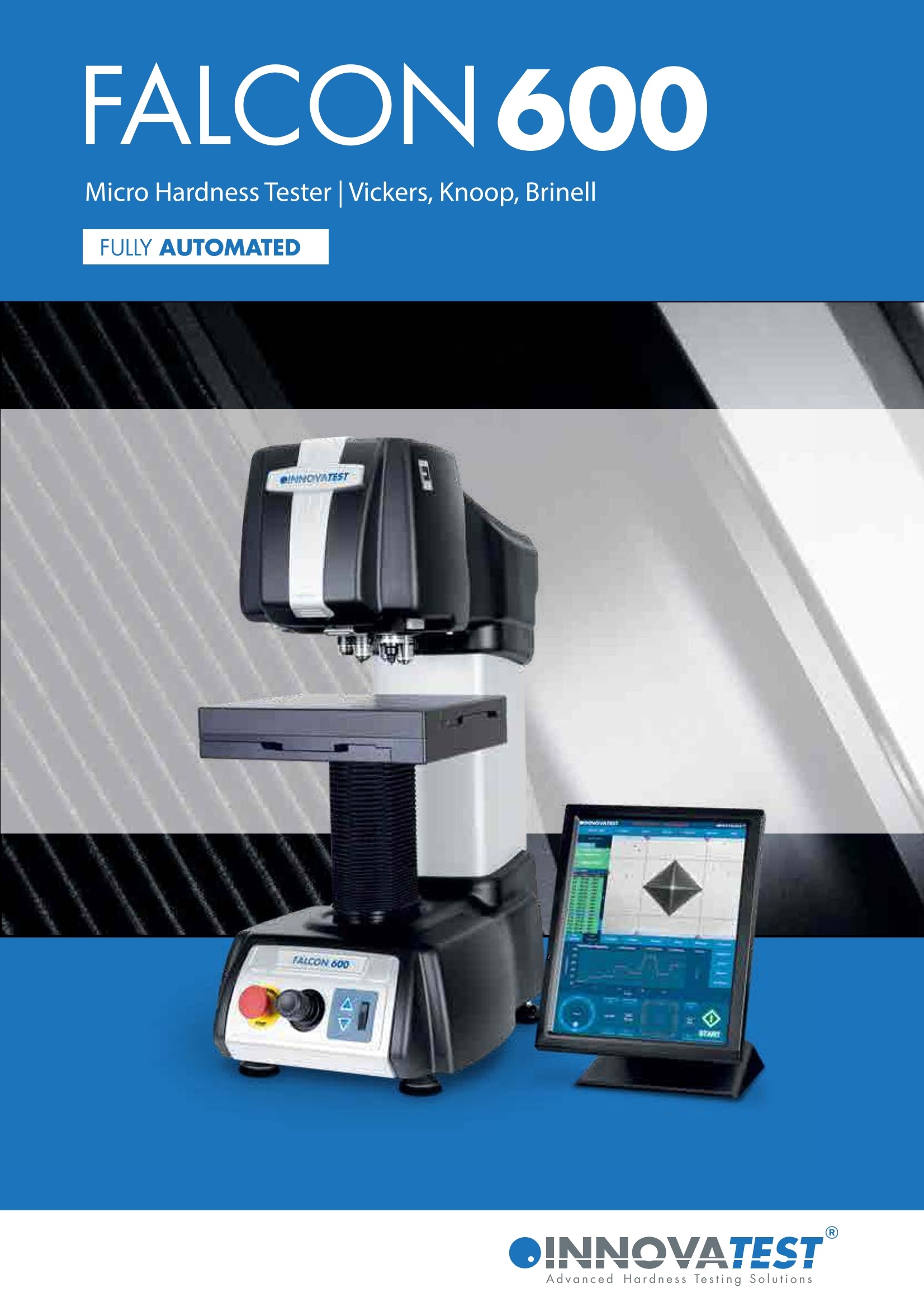

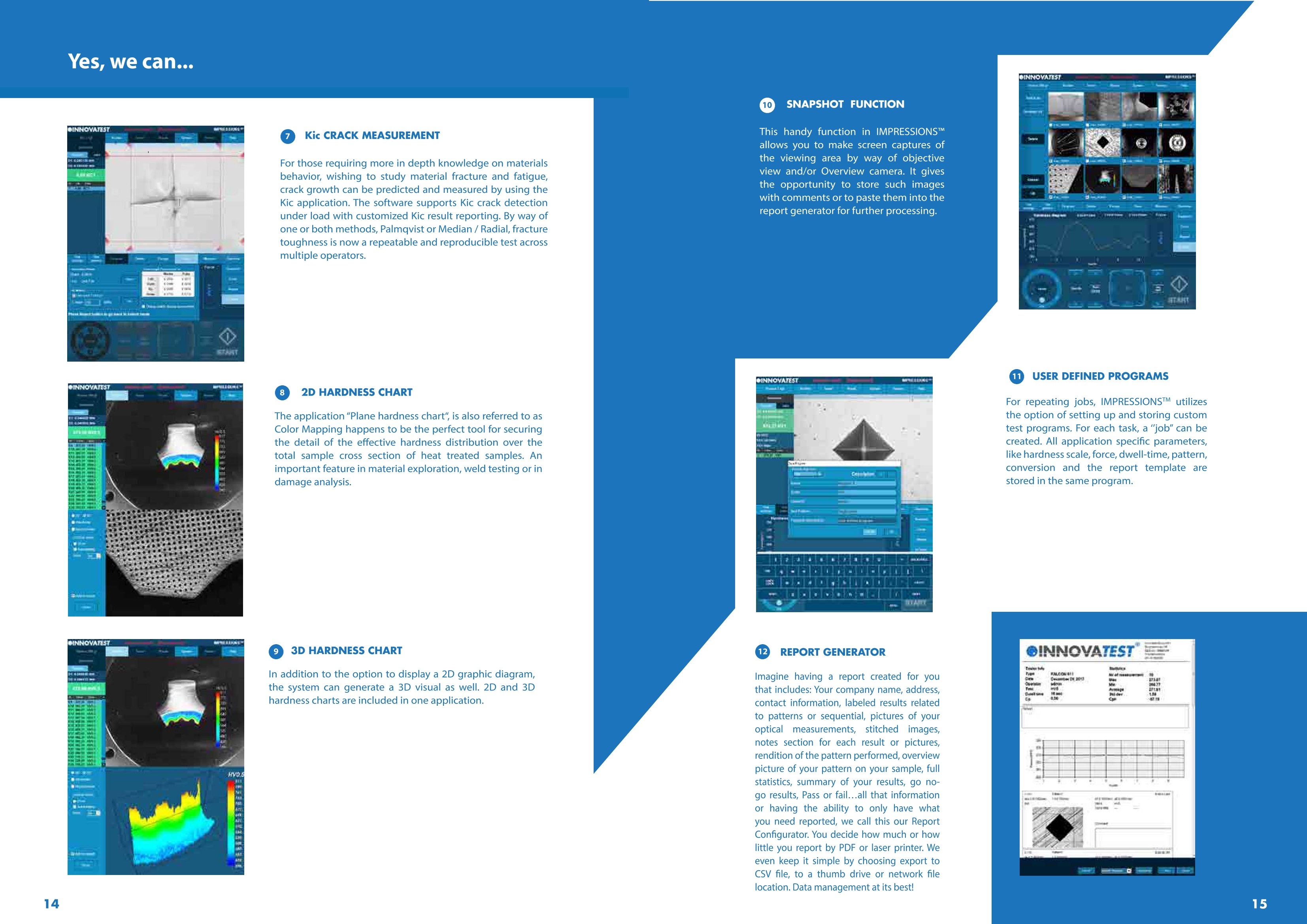

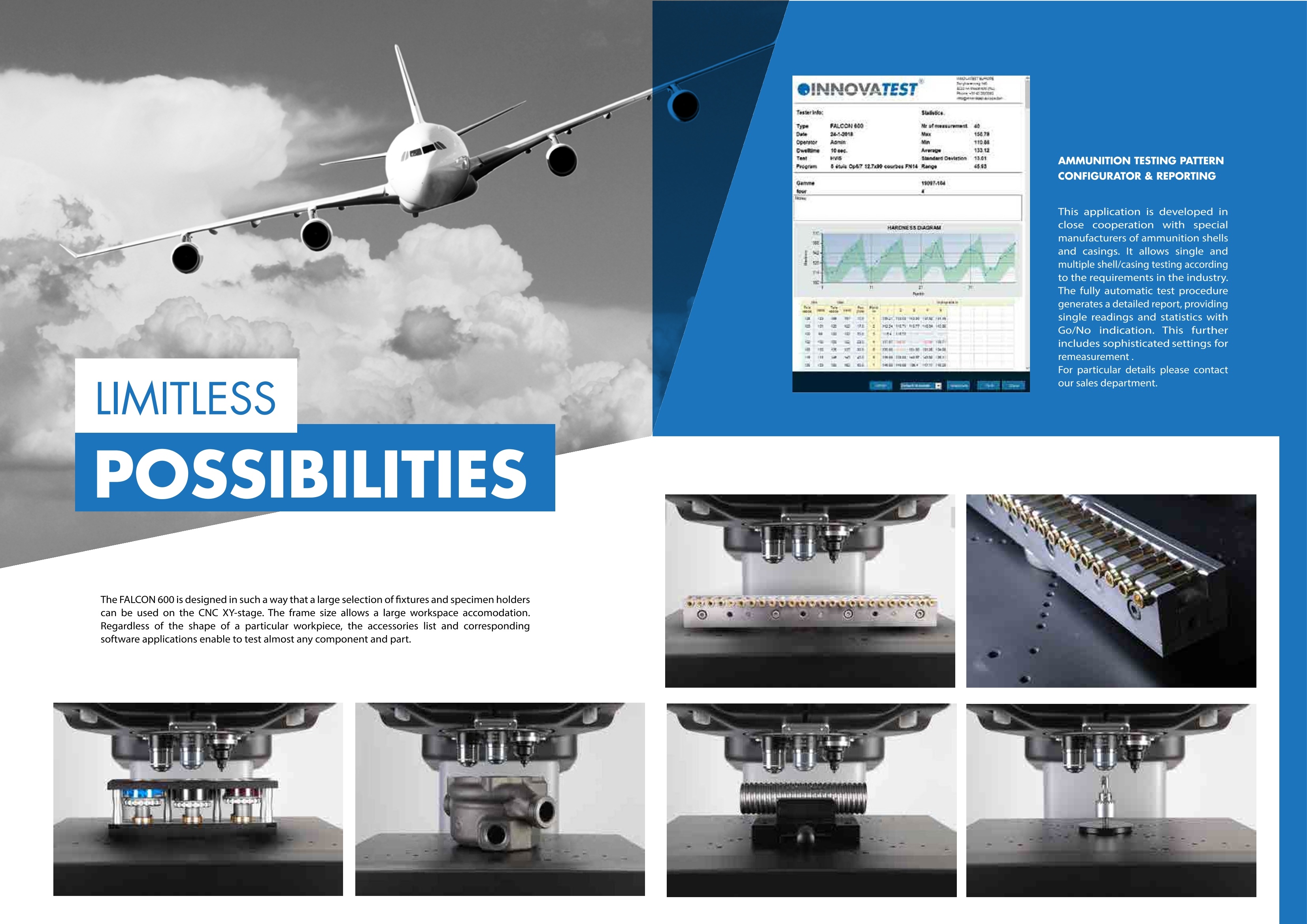

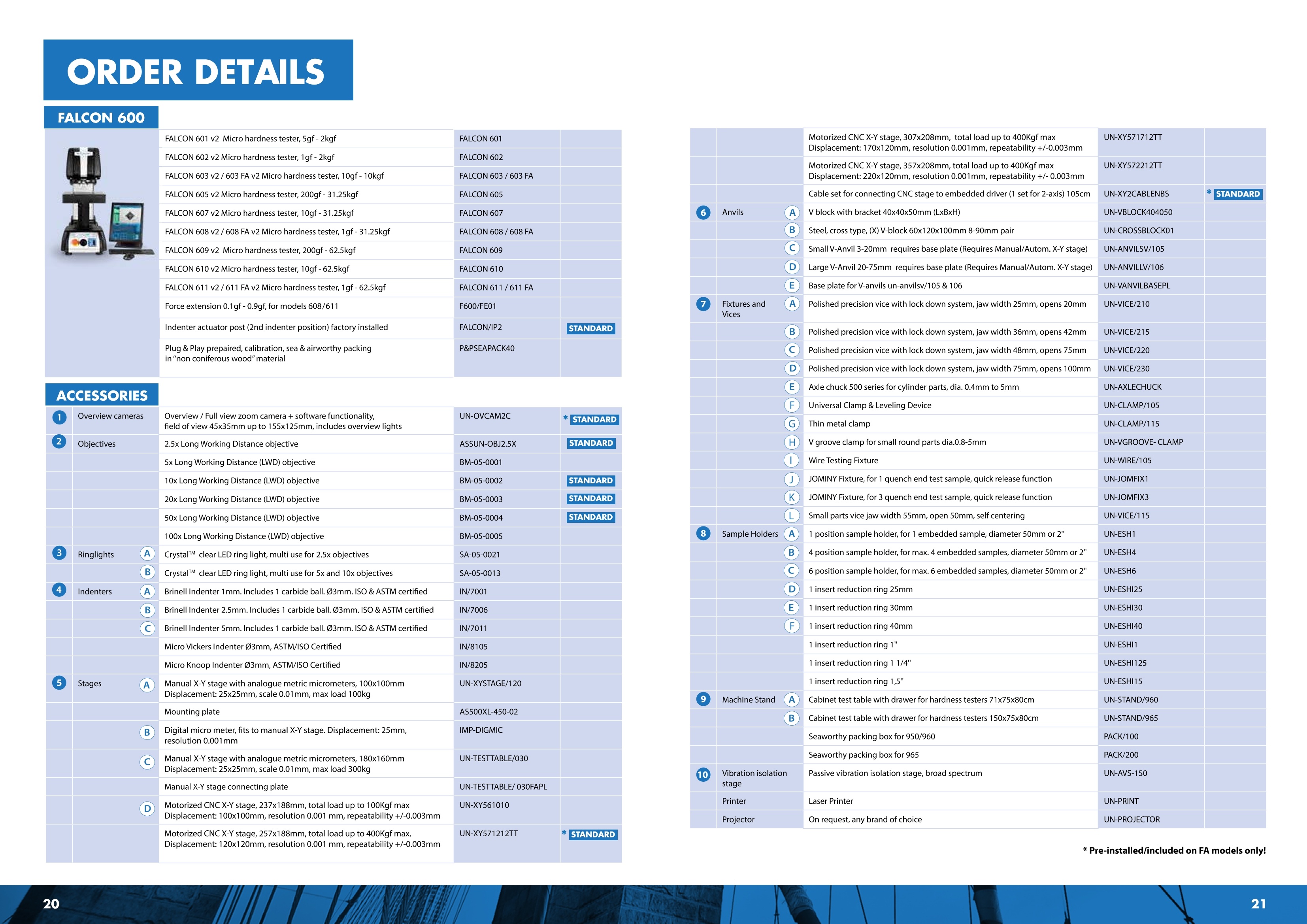

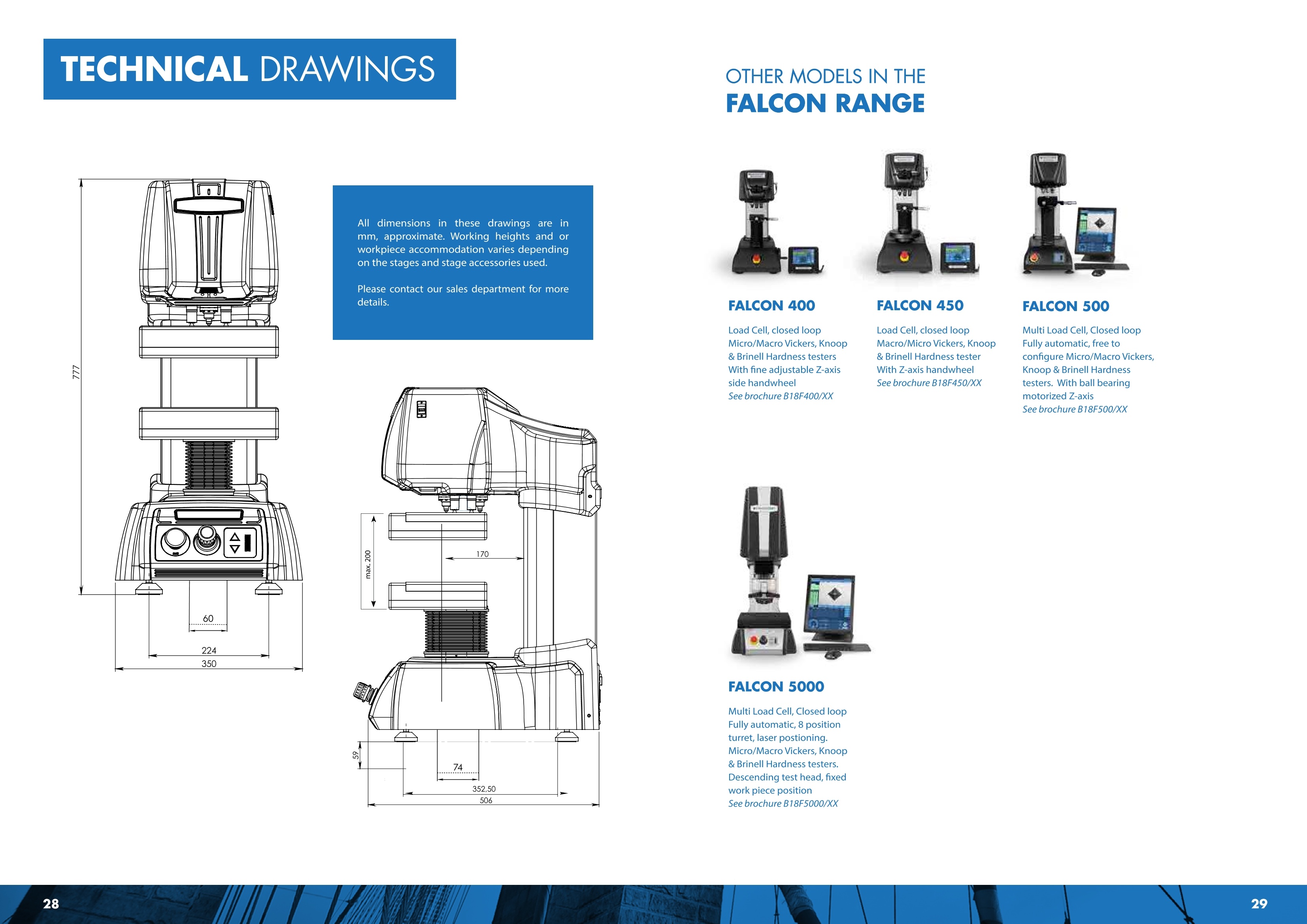

4 AUTOMATIC IMAGE FALCON600 Micro Hardness Tester | Vickers, Knoop, Brinell FULLY AUTOMATED FALCON600 ECTE BTNT Q FALCON c600 Our vision, your future... The FALCON 600 Automated Hardness Testing System provides a fully integrated platform for your complete Vickers,Knoop & Low Force Brinell hardness testing needs. Coming from a leading edge of mechanical design, with a range of CNC stages and best in class optics, 18 Megapixels,4K, full colorimage technology,to a fully featured, easy to use, User Interface. Astandard force range of 1gfto 62.5kgf,optional going down to forces as low as 0.1gf, to be used in combination with any thinkable software application,provides a micro hardness testing machine for today, tomorrow and better... for the future. Load cell,closed loop,force feedback system A FORCE RANGE THAT SETS NEW STANDARDS! =Extended range available starting from 0.1gf HIGHLIGHTS Multi Load Cell, Closed Loop force application system, error <0.25% 6 position turret, 2 indenter positions, 4 LWD objectives installed (included) Turret collision detection and workpiece retraction safety system 18 Mega Pixel, 4K, full color integrated camera system Full X-Y stage overview camera, optical zoom system, variabele field of view TTL power LED with color filter, Dual bank power LED stage illumination Large CNC X-Y stage 300 x225mm, Z-axis with ball bearing spindle (standard) Integrated system controller, i7 processor, Dual MSSD Raid system storage Industrial 15" touch screen, option for second screen 15" to 55" or projector Top-class replaceable body parts, shock proof ABS covers BOUNDLESS Multi loadcell,force actuator INNOVATION e PML 60/0WD5.1 Z-AXIS BALL SCREW Precision movement 40 6c0 Observe, Think,Try, Change... ( Ri g id i t y and p erp e ndicular inde n t e r positioning a r e cruc i al to o b ta i n Vickers i ndents with a p e rf e ct g eom etry. Re-in v ented , adju s table indentor actuators pro v ide main t en a nce free, s m oo t h fo r c e a p p li c a t ion, easy to acc e ss an d e asy to repla c e inde n ters . St andard i n tegra t ed X - Y s t age o verv i e w c am e ra, with optica l zoom , reduces application set up time dram a t i ca ll y. ) TECHNOLOGY Changing the game... 6 POSITION PRECISION TURRET & OPTICAL SYSTEM CONNECTIVITY, CONTROL & QUALITY ASSURANCE The 6 position turret is supplied as a standard feature on all 600 models and allowsto install indenters for Vickers, Knoop and Brinell (balls 1mm & 2.5mm) testing.Factory installed, the FALCON 600 has four objectives 2.5X, 10X, 20X,50X that, incombination with the 18 Megapixel camera, with 4X digital zoom, supersede theneed to buy larger magnification objectives. The system has bi-directional in and output channels.Tester control can be conducted remotely and supportsfor instance, but not limited to robotic systems. Test valuescan be exported as single values or as string of data to behandled by 3rd party quality evaluation software. Q-DAS certified.(Optional) STAGE OVERVIEW CAMERA Create magnified sample overview with the standard on-board, auto focus,optical & digital zoom, overview camera. The field of view of this sophisticatedfull color camera system does not limit you to one field of view, but gives a ZOOMrange of 45 x35mm up to 155x125mm without the need to use time consumingscan and stitch functions. Once the viewing area needs to be larger than the zoom range, scanning andstitching can be selected to create full stage overview. Click and go is one ofthe standard testing features of the overview camera. Just click randomly ondesignated area's and push"start". All tests run automatically. The pattern videooverlay function eases positioning of multiple test rows or patterns across thespecimen. The pattern video overlay scales automatically with every magnification,stepless, while the zoom camera decreases or enlarges the overview. EALcON 600 DYNAMICZ-AXIS CONTROL & COLLISION DETECTION A high end ball bearing Z-axis spindle is one of the very unique functions. Z-axisdisplacement at an accuracy of micron's supports ultra-fast auto focus. Z-axiscontrols are nearly limitless; CNC as a result from a test program, by touch screenindicators, from the built in joy stick, by the scroll wheel of the mouse, by fast upand down buttons or from a scroll wheel on the front of the machine. Positioninghas never been this easy. Speed control related to your own movement; (0.01 upto 20 mm/s). To avoid any collision between the work piece and the turret, the Z-axis iscontrolled by a flawless collision detection and Z-axis retraction system.So neither the tester nor the workpiece are exposed to any damage. 15"HD TOUCH SCREEN OPERATOR INTERFACE All machine control and process workflow can easily be operated from the 15"industrialcapacitive touch screen. At choice a second 15"or larger screen can be connected. HIGH SPEED CNC MOTORIZED XY-STAGE Save time and improve efficiency with one of the high speed, highly accuratemotorized XY-stages. Available in variable sizes from standard, to large andextra-large. Enable automated sequencing of multiple samples. The ultra-highaccuracy and repeatability guarantee precise positioning of indents and allowre-evaluation of any measurement points in batch or single view. Repeatabilitywithin 3 micron. SHOCK RESISTANT ABS MACHINE COVERS The tester is fitted with a high-end external shell structure. All in a unique designwith high-end aluminium panels. The shock proof and damage resistant ABSmachine covers can withstand the harshest environment. AUTO FOCUS Fast & precise, observe how IMPRESSIONSTM findsfocus from a large distance, as far as the travel ofthe Z-axis allows. Algorithms used for close distanceautofocusing set new standards in AF speed. AUTOMATIC MEASUREMENT Manual positioning of filar lines is no longerrequired.IMPRESSIONSTM rrefinedd mreasurementalgorithms detect indents even on very poor orscratched surfaces and measure the relevant indentdimensions according to standards. Stay in controlby switching to manual measure mode and have theoption of adjusting measurements by touching thescreen or using the mouse. Filar lines can be coloredto give the best contrast against the specimen'ssurface.To assure that measurements meet relevantstandards on symmetry, enable the automaticindent check. All hardness values can be convertedto other scales according to ISO 18265, ISO 50150,ASTM E140. Evaluate whatever you want,-- because what gets measured, gets produced... ILLUMINATION SETTINGS IMPRESSIONSTM software automatic illumination system adapts to the correct illumination regardlessof the sample surface quality, wherever on the sample, independent from material (steel, carbide,coated or ceramic). Contrast, Brightness and program, can be set automatically for each measurementor controlled manually. Sharpness can be stored with the pre-determined test REFINED IMAGE DETECTION Complex, refined algorithms ensure reproducible measurements ondifferent materials and even on scratched and damaged surfaces. AFRESSCWS- The Graphical User interface (GUI), contains Industry preferred applications, and offers easy tolearn, advanced workflow control. A simple test can be set up and conducted in about 3 seconds...IMPRESSIONSTMlayout & functions will match not only your particular application requirements, butalso meet the needs and preferences of your operators. A user level management system maximizestheir comfort and efficiency. INNOVAFEST PATTERN TESTING The IMPRESSIONS"M pattern editor allows theuser to create any number of test patterns witha large number of variable settings. Create testpatterns with great precision and freedom.Verify the settings in the preview mode.Drag &drop patterns from one test sample to anothersample. Live vision technique over zoomoverview camera, no image stitching required. HARDNESS OF SCREW THREADDECARBONIZED ZONE (ISO898-1) A specialized software tool of IMPRESSIONS" allows youto set up and conduct fully automatic testing as perISO898-1 for screwthreadmeasurementof(de)-carbonized part. Report Generator is enhanced vwithreporting features for this application. Combine different patterns and even differenttest forces in one program, and run them fullyautomatically. All test points can be identifiedindividually or to customer specifications. Thelabel is shown in the test result list and in thetest results overview and in the results printout. An important function for sample analysesat the end of a test and in the future for reviewof previous tests. CHD, SHD,NHD How do you increase throughput in your lab?Make the most common testing design aseasy to set up as it is to perform automaticallyand still adhere to the applicable standards.CHD/SHD/NHD testing can be started directlyfrom the surface view or from the overview.Additional core points of hardness can bedefined separately for NHD measurements.The distances oftest points are automaticallysetto a minimum distance, following the standard,to assure correct testing is conducted. Timesaving test mode "complete all indentations -then evaluate"and"auto-stop"to complete testseries as soon as the lower hardness limit hasbeen reached. Report Generator is enhancedwith reporting features for this application. EDGE DETECTION Technology that automatically or at a mouse click recognizesthe edge of your sample. This helps to determine and fix thedesired starting position for CHD or other pattern testing jobs. INNCDVATESTAUTOMATIC CONTOUR SCANNING WELD INSPECTION (ISO 9015) This application scans the entire outline (or partial) area ofa sample. The function can be used with an objective byusing the overview zoom camera for high speed scanning.The system scans the entire outline defined and stores allrelevant data in the test program. This especially developed tool enables you toconduct hardness testing on welded parts orsegments according to ISO standard. Settingup the pattern according to the requirementsbecomes "easy-to-do", due to pre-set test pointsin the different zones of the weld and automaticcorrelation between test points. The systemwill run a fully automatic test procedure anddisplay and record the results accordingly. ReportGenerator is enhanced with reporting features forthis application. Subsequently, a limitless number of test points can beinserted into the scanned image, or be set at selecteddistances (offset), relative to the edge. This advanced featureenables the hardness testing procedure to be performedatomically. An excellent feature to combine with 2D or 3Dhardness mapping,also known as"plane hardness chart" Kic CRACK MEASUREMENT For those requiring more in depth knowledge on materialsbehavior, wishing to study material fracture and fatigue,crack growth can be predicted and measured by using theKic application. The software supports Kic crack detectionunder load with customized Kic result reporting. By way ofone or both methods, Palmqvist or Median / Radial,fracturetoughness is now a repeatable and reproducible test acrossmultiple operators PINNOVATEST 2D HARDNESS CHART The application "Plane hardness chart" is also referred to asColor Mapping happens to be the perfect tool for securingthe detail of the effective hardness distribution over thetotal sample cross section of heat treated samples. Animportant feature in material exploration, weld testing or in. damage analysis. 3D HARDNESS CHART In addition to the option to display a 2D graphic diagram,the system can generate a 3D visual as well. 2D and 3Dhardness charts are included in one application. This handy function in IMPRESSIONSTMallows you to make screen captures ofthe viewing area by way of objectiveview and/or Overview camera. It givesthe opportunity to store such imageswith comments or to paste them into thereport generator for further processing. REPORT GENERATOR Imagine having a report created for youthat includes: Your company name, address,contact information, labeled results relatedto patterns or sequential, pictures of youroptical measurements, stitched images,notes section for each result or pictures,rendition of the pattern performed, overviewpicture of your pattern on your sample, fullstatistics, summary of your results, go no-go results, Pass or fail...all that informationor having the ability to only have whatyou need reported, we call this our ReportConfigurator. You decide how much or howlittle you report by PDF or laser printer. Weeven keep it simple by choosing export toCsV file, to a thumb drive or network filelocation. Data management at its best! USER DEFINED PROGRAMS For repeating jobs, IMPRESSIONSTM utilizesthe option of setting up and storing customtest programs. For each task, a "job" can becreated. All application specific parameters,like hardness scale, force, dwell-time, pattern,conversion and the report template arestored in the same program. / AMMUNITION TESTING PATTERNCONFIGURATOR & REPORTING This application is developed inclose cooperation withT specialmanufacturers of ammunition shellsand casings. It allows single andmultiple shell/casing testing accordingto the requirements in the industry.The fully automatic test proceduregenerates a detailed report, providingsingle readings and statistics withGo/No indication.i. TThis furtherincludes sophisticated settings forremeasurement.For particular details please contactour sales department. LIMITLESS POSSIBILITIES The FALCON 600 is designed in such a way that a large selection of fixtures and specimen holderscan be used on the CNC XY-stage. The frame size allows a large workspace accomodation.Regardless of the shape of a particular workpiece, the accessories list and correspondingsoftware applications enable to test almost any component and part. OUOOO心oce SUPPORTYOURBEST TESTINGRESULTS With our rigid designed Bench stands Rock solid bench stands 100% retractable drawer, bearing guidance, max 100kgload. Rubber anti slip bottom Lockable cabinet, 300mm highAdjustable feet,(+/-50mm height adjustable toreach ergonomic working position)Made of corrosion resistant zinc plated steel withRAL powder coatingCarrying capacity of 400kg Top surface made of 50mm Plywood with1.5mm chemical resistant plastic plating,edges made of shock resistant 3mm ABS side linerIndustrial quality, for workshop or laboratory Designed for hardness testing instruments,painted in INNOVATESTRAL colors matchingourtesters. UN-STAND/96071x75x80 cm UN-STAND/96551150x75x80 cm Schematic overview of the configuration options, standard and optional accessories ORDER DETAILS ACCESSORIES ISO/ASTMVerification BRINELL direct and indirect verification/calibration & certification in compliancewith ISO & ASTM,NADCAP. Includes direct force and indirect verification report(block readings), GR & R report, flat fee for selected common scales,per scale. CALCEFRDW/1B STANDARD VICKERS direct and indirect verification/calibration & certification in compliancewith ISO & ASTM, NADCAP. Includes direct force and indirect verification report(block readings), GR & R report, flat fee for selected common scales, per scale. CALCEFRDW/1V KNOOP direct and indirect verification/calibration & certification in compliancewith ISO & ASTM, NADCAP. Includes direct force and indirect verification report CALCEFRDW/1K (block readings), GR & R report, flat fee for selected common scales, per scale. Cover Anti Static machine cover 453x690×945mm UN-TESTERCOVER06 ORDER DETAILS SOFTWARE SPECIFICATIONS HARDNESS SCALES VICKERSISO 6507ASTM E384, E92JIS B 7725 HV0.001|HV0.002|HV0.003|HV0.004|HV0.005|HV0.006|HV0.007|HV0.008|HV0.009 HV0.010|HV0.015|HV0.020|HV0.025|HV0.050|HV0.1|HV0.2|HV0.3|HV0.5HV1 |HV2 HV2.5|HV3|HV4|HV5|HV10|HV20|HV25|HV30|HV40|HV50 *Extended range *(HV0.0001-HV0.0009 increases with steps of HV0.00005) Klc Fracture toughness KNOOP ISO 4545 All Vickers forces & scalesHK0.001|HK0.003|HK0.005|HK0.01|HK0.015|HK0.02|HK0.025|HK0.05|HK0.1 |HK0.2HK0.3|HK0.5|HK1|HK2|HK5 ASTM E92JISZ 2251 BRINELL HB1/1|HB1/1.25|HB1/2.5|HB1/5|HB1/10|HB1/30|HB2.5/6.25|HB2.5/7.8125 HB2.5/15.625|HB2.5/31.25|HB2.5/62.5|HB5/25|HB5/62.5 ISO6506,ASTM E10 JIS Z 2243 CONVERSIONS Conversion to other hardness scales according to ASTM E140, ISO 18265, GB/T 1172 Force application Multi-load cell, closed loop, force feedback system Test forces 0.0001kgf -62.5kgf Force range per model FALCON 601 5gf-2kgf FALCON 602 1gf-2kgf FALCON 603 / FA 10gf-10kgf FALCON 605 200gf-31.25kgf FALCON 607 10gf-31.25kgf FALCON 608/ FA 1gf-31.25kgf FALCON 609 200gf-62.5kgf FALCON 610 10gf-62.5kgf FALCON 611/ FA 1gf-62.5kgf Test force tolerance <0.25% for test force 100gf to 62.5kgf <0.5% for test force below 100gf Dwell time settings Default 10 seconds, user defined.Up to 999 seconds TURRET Motorized turret Objectives Indenters Camera 1 (objective) Camera 2 (overview) Ultra-fast, 6 position turret, 2 indenter positions, 4 objective positionsLong working distance 2.5x, 5x, 10x, 20x, 50x, 100xCertified indenters (ISO/ASTM) available at choice18 Mpx, HD,4K+, Machine vision systemFull HD,Optical zoom system, variable FOV 45x35mm-155x125mm SYSTEM Electronic system High performanceembedded controller,i7, mSSD 120 GBxx, Standard (Recommended)MS Windows°10 operated,up to 8 years*INNOVATEST warranty Electronic system High performance external controller, i7 or i9, mSSD 120 GBxx, (Optional) MS Windows° 10 operated, 1 year factory warranty CNC support CNC controller (for motorized stages) or stage accessories Screen(s) 15"portrait mode capacitive touch screen, second screen option Display resolution 0.01 HV, HK,HB Statistics Total test, max, min, average,range, standard deviation, All in real time after each test Hardness conversion Rockwell, Rockwell Superficial, Vickers, Brinell,Knoop, Leeb & Tensile Software IMPRESSIONS*MV2, work flow system & tester control Data storage capacity Internal and external mSSD, SSD or HDD Data output XML, CSV, Certified for Q-DAS (optional) Connectivity 5 USB ports, RJ45 Ethernet LAN, W-LAN, RS-232, Blue Tooth, 5 Axis CNC & motorized X-Y stage connector, Dual HDMI screen connectors Printer A4, A3 full color laser printer (optional) GENERAL Machine dimensions 777mm (H)x350mm(W)x506mm (D) Workpiece 200mm (H)x170mm (D) accommodation Machine weight 80kg Power supply 100VAC to 240VAC,50/60Hz, single phase Operating temperature10℃ to 35C Power consumption 100W Humidity 10% to 90%,non-condensing Noise <70 db(A) * Check individual warranty conditions 60 224 350 506 FALCON 400 Load Cell, closed loopMicro/Macro Vickers,Knoop& Brinell Hardness testersWith fine adjustable Z-axisside handwheelSee brochure B18F400/XX Changes in products and/or product specificationscan emerge due to newtechnologies and continuousdevelopment. We reserve the right to changeor modify specifications ofthe products without priornotice. We recommend youto contact our sales office forup-to-date information.1. Brochure B18F600/18/EN@ All rights reserved, 2019 Distributor: CORPORATE HEAD OFFICE INNOVATEST Europe BV Manufacturing, Distribution & ServiceBorgharenweg 140 6222 AA MAASTRICHTThe Netherlands Phone: +31 43 3520060 Fax:+31 43 3631168 info@innovatest-europe.com www.innovatest-europe.com INNOVATESTDeutschland GmbHSales & Service INNOVATEST Shanghai Co.,Ltd. INNOVATEST USA Company Sales & Service Sales & Service Phone: +49 245 670 59 500info@innovatest-deutschland.comwww.innovatest-deutschland.com Phone:+8621 60906200info@innovatest-shanghai.comwww.innovatest-shanghai.com Phone: +1 267 317 4300info@innovatest-usa.com www.innovatest-usa.com INNOVATEST Polska sp.z.o.oSales & Service INNOVATEST Japan Co., Ltd.Sales & Service INNOVATEST South East AsiaSales & Service Phone:+81335273092 info@innovatest-japan.comwww.innovatest-japan.com Phone: +65 64511123info@innovatest-singapore.comwww.innovatest-singapore.com INNOVATESTAdvanced Hardness Testing Solutions 内燃机燃烧室由活塞、气缸套、喷油嘴、气缸盖等部件组成,燃烧室的设计好坏影响到燃油系统、进气系统是否能够实现良好的相互配合,进而得到优越的性能。如果燃烧室设计不好,燃烧室温度过高,会出现活塞烧熔,油嘴断裂、烧机油等一系列恶性故障。测量燃烧室各个部件在不同位置的工作温度成为一项重要工作,一般工程上测量常用硬度标定法。硬度标定法的基本原理是当某一金属材料承受一定时间、一定温度的工况过程时,其硬度与其所受的温度呈近似的线性关系。测量活塞、气缸套、气缸盖或油嘴时,将这种金属制成螺塞状或螺钉状,植入被测部件内,再通过测量工作后被测部件内该金属的硬度,与已获得的螺塞回火温度-硬度曲线进行比较,可获得该工况下被测部件的最高温度。一般螺塞状金属用GCr15或35钢制成,能很好的满足使用要求。 硬度测量时,一般用维氏硬度计测量,测量结果具有误差小、计算结果准确等优点。有时候待测点较多,检测任务非常繁重,建议选用全自动维氏硬度计检测,大大提高工作效率,减少人力及物力。案例以下为测量某一个燃烧室部件温度的案例过程:取特定一批材料,用已知温度进行淬火并回火,每一组回火温度有三个试样,每个试样检测三次维氏硬度值,结果列于下表:对数据进行整理,结果如下:根据上表中的数据作出硬度随回火温度变化曲线:回归方程:X其中:X:温度(℃)Y:硬度(HV)相关系数:-0.997251、硬度检测结果及按回归方程算出的温度:将第一~第六缸的检测结果作温度-位置分布曲线图,按位置顺序排列,见下图:说明:由于部分硬度塞未能提供,故分布曲线断断续续。观察这些图上数据,六个缸的温度整体来说不高;六个缸的最高温点数据中,最高者为356℃,相对较低者为272℃,其中,各缸的最高温点数据如下:第1缸:301℃(位置点1-9);第2缸:288℃(位置点2-7);第3缸:302℃(位置点3-2);第4缸:272℃(位置点4-9);第5缸:356℃(位置点5-12);第6缸:306℃(位置点6-13)。看了上面这个案例,用“硬度标定法”测量燃油系统部件工作温度,您会了吗?

确定

还剩15页未读,是否继续阅读?

荷兰轶诺为您提供《内燃机燃烧室中维氏硬度检测方案(硬度计)》,该方案主要用于汽车电子电器中可靠性能检测,参考标准--,《内燃机燃烧室中维氏硬度检测方案(硬度计)》用到的仪器有荷兰轶诺硬度计|显微硬度计|维氏硬度计FALCON 600 、荷兰轶诺硬度计 | 显微维氏硬度计FALCON 500、布氏硬度计洛氏硬度计维氏硬度计显微硬度计配件/硬度块、 布氏硬度计洛氏硬度计维氏硬度计显微硬度计配件/压头

相关方案

更多