方案详情

文

应用HS-SPME-GC-MS结合电子鼻和电子舌对不同NaCl替代品的干发酵香肠的风味特征进行了表征.

方案详情

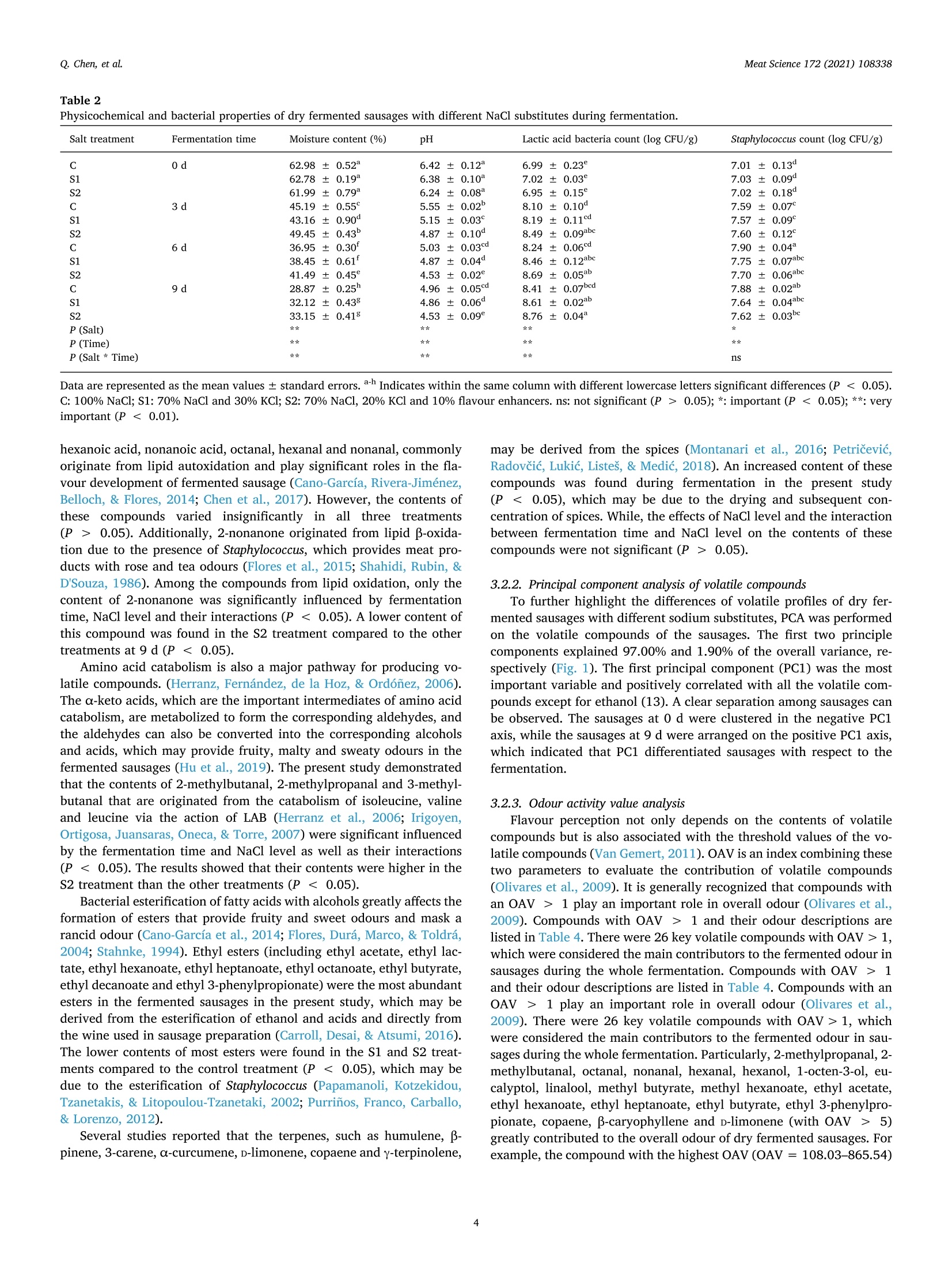

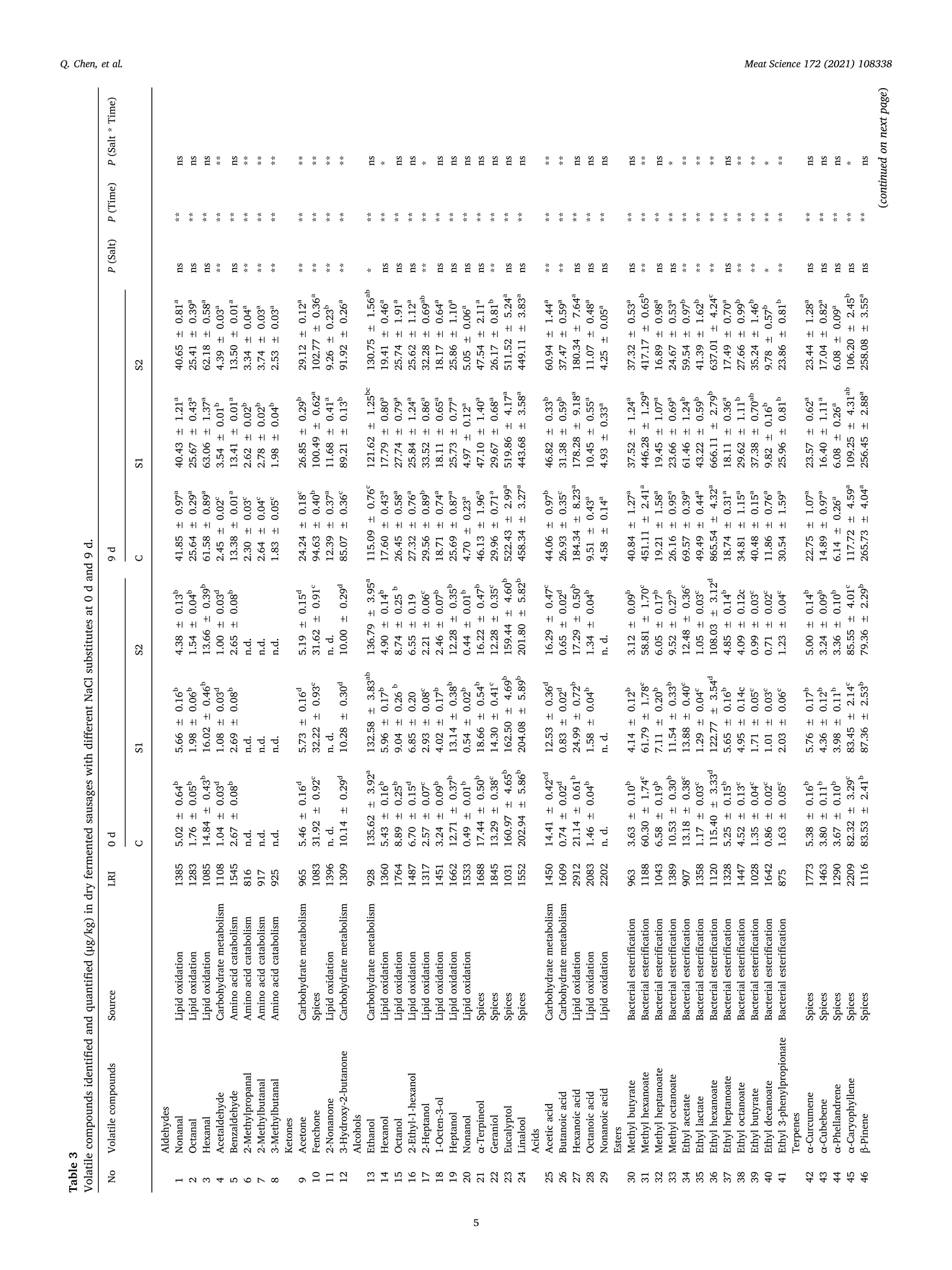

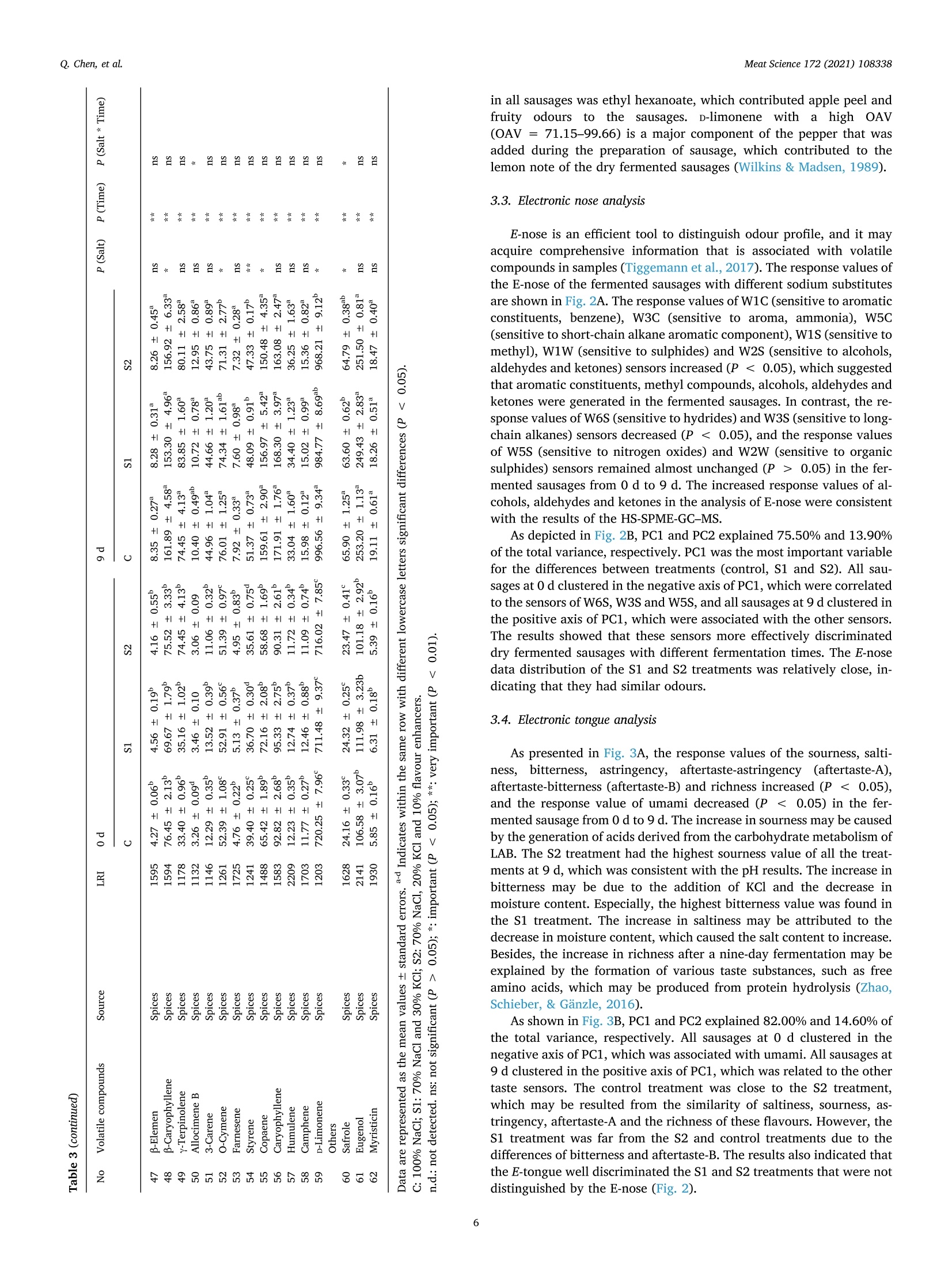

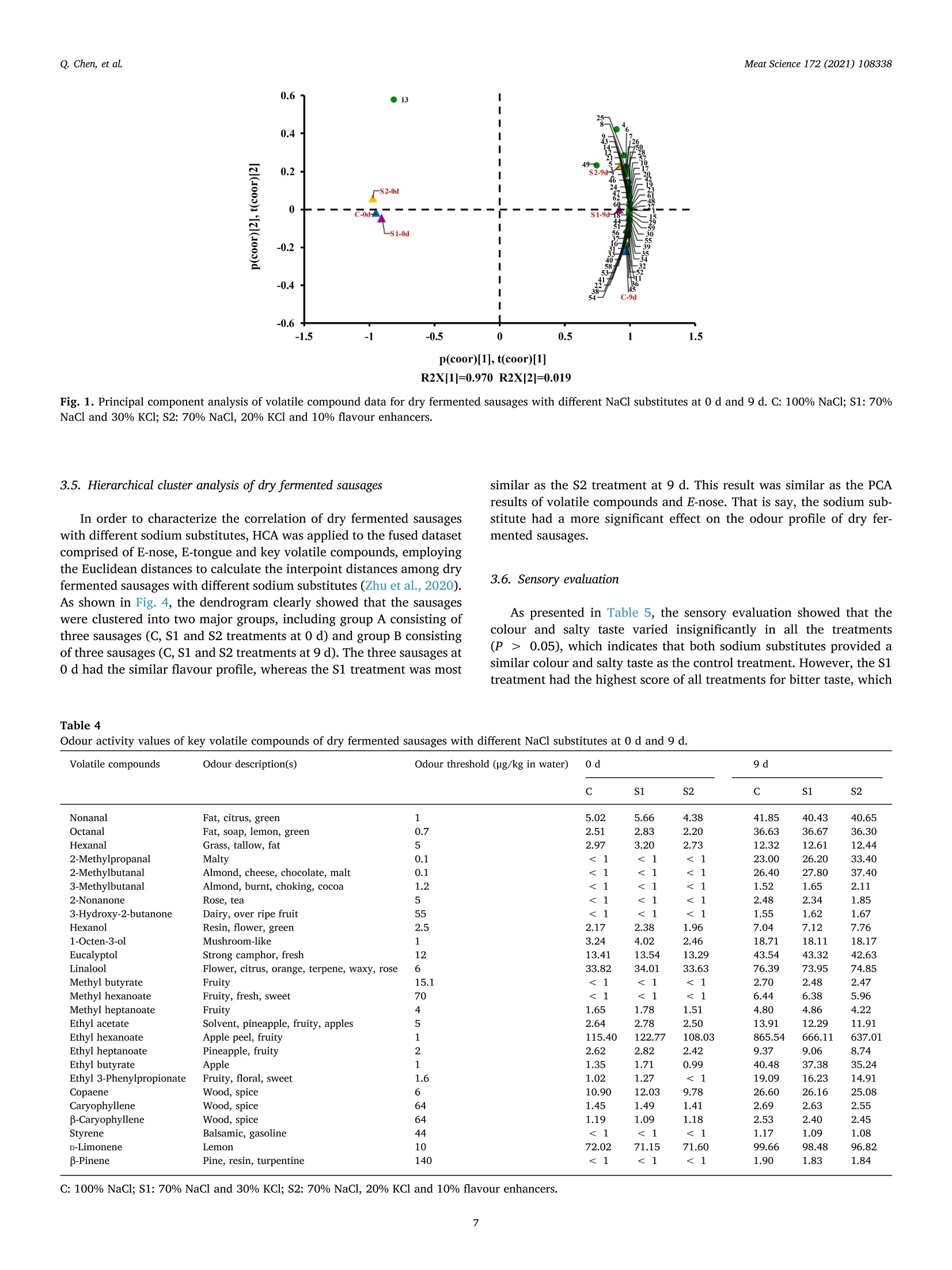

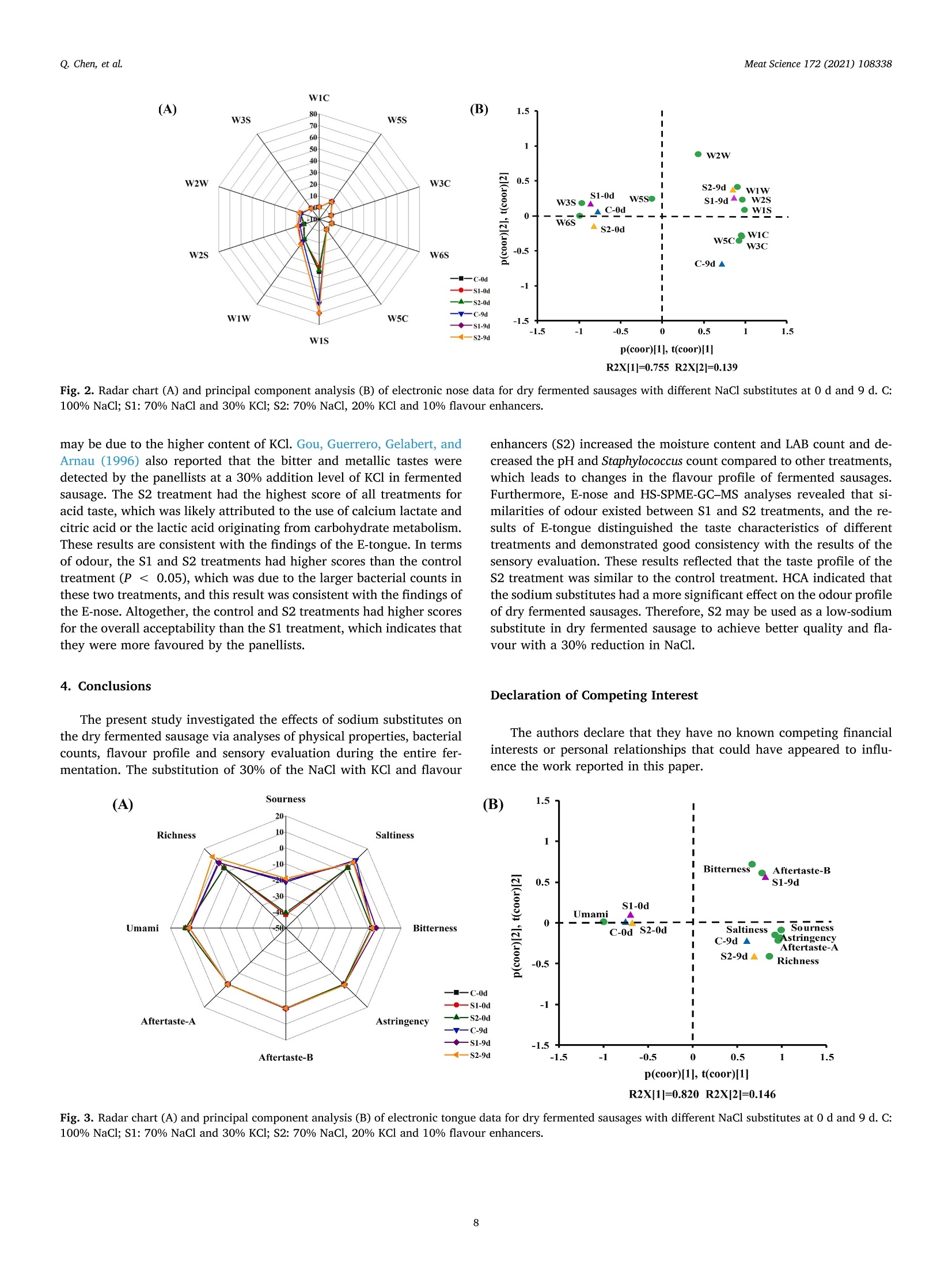

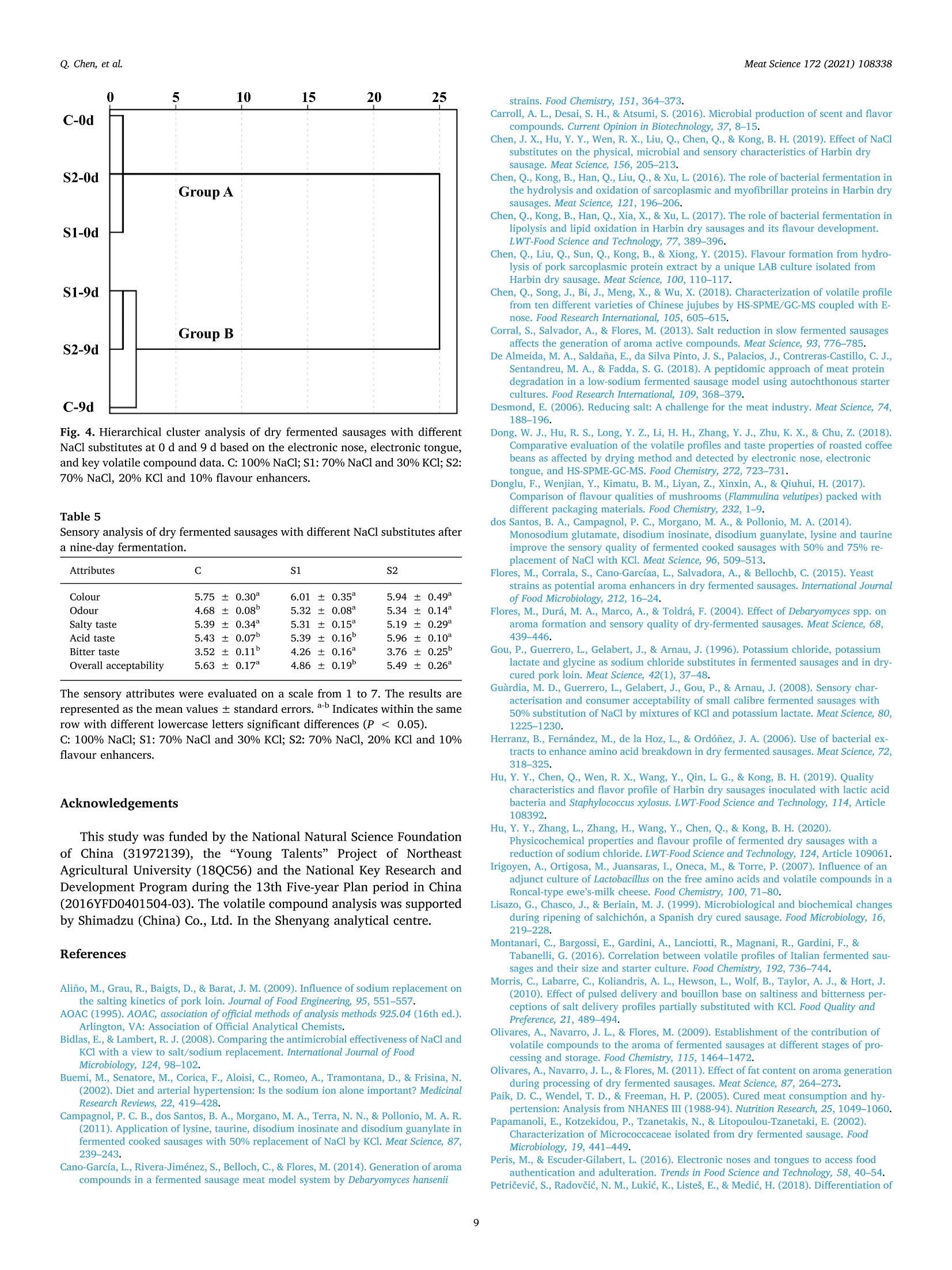

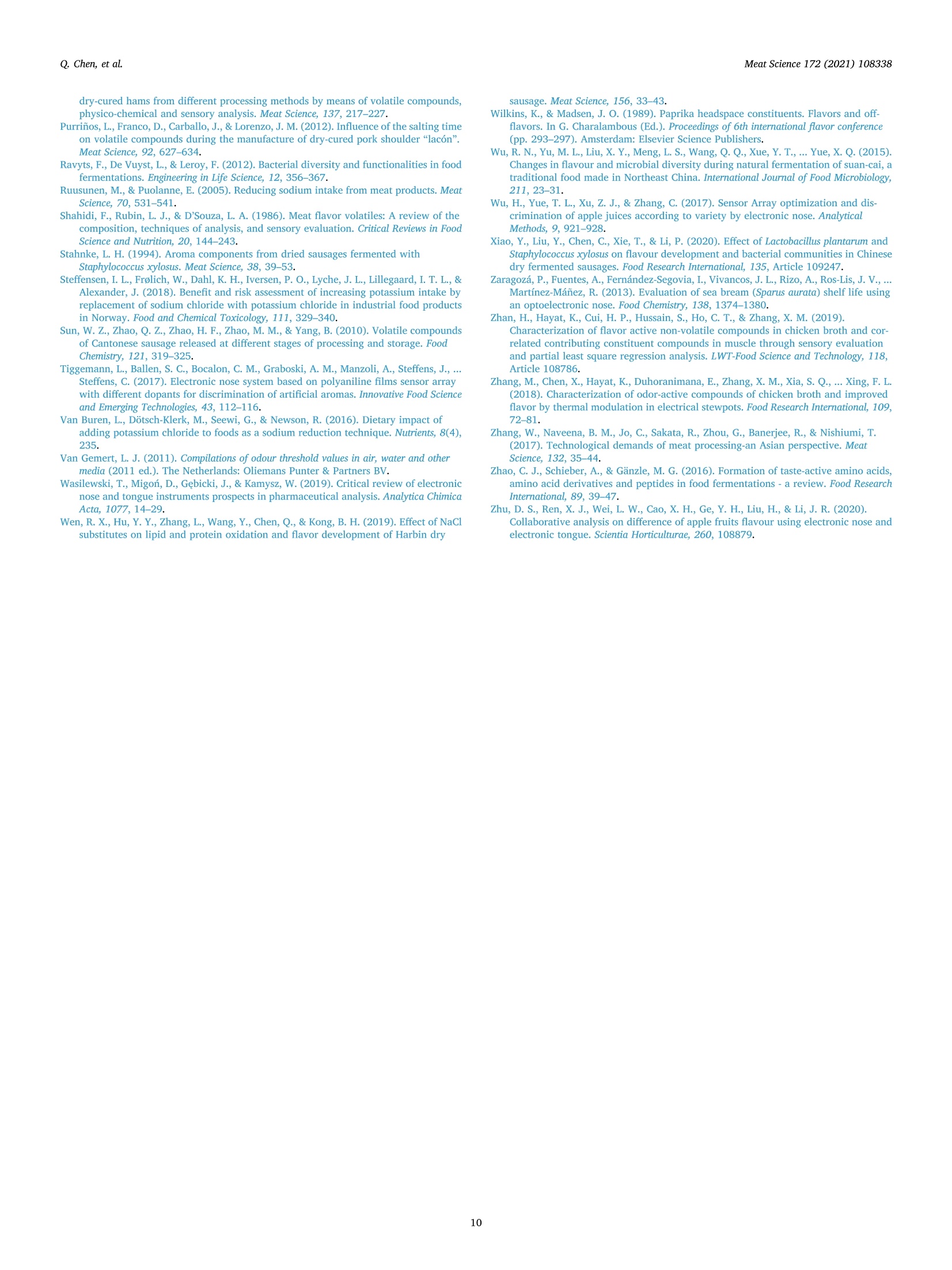

Meat Science 172 (2021)108338Contents lists available at ScienceDirect Meat Science 172 (2021) 108338Q. Chen, et al. Meat Science journal homepage: www.elsevier.com/locate/meatsci Characterisation of the flavour profile of dry fermented sausages withdifferent NaCl substitutes using HS-SPME-GC-MS combined with electronicnose and electronic tongue Qian Chen , Yingying Hu , Rongxin Wen, Yan Wang, Ligang Qin*, Baohua Konga* Northeast Agricultural University, Harbin, Heilongjiang 150030, China 'Shimadzu (China) Co., LTD., Shenyang, Liaoning 110000, China A RTICLEIN F O A B S T R A C T Keywords:Sodium substitutesFlavour enhancersDry fermented sausageFlavour profileElectronic noseElectronic tongue The effects of different sodium substitutes on the physical and bacterial properties, flavour profile and sensoryevaluation of dry fermented sausage were investigated. There were three different salt formulations, includingcontrol (C: 100%NaCl), S1 (70%NaCl and 30%KCl) and S2 (70%NaCl, 20%KCl and 10% flavour enhancers).Higher moisture content and lactic acid bacteria count, and lower pH and Staphylococcus count were observed inNaCl substitution treatments compared to the control (P <0.05). Sixty-two volatiles were detected in sausages,and 26 compounds were regarded as key volatile compounds based on the odour activity values. The electronictongue result and sensory evaluation showed that the taste profile of S2 treatment was similar to controltreatment; and the electronic nose, volatile compound results and hierarchical cluster analysis showed that thesodium substitutes had a more significant effect on the odour profile. Overall, S2 may be an ideal low-sodiumsubstitute to achieve a 30% reduction in NaCl and provide a better flavour profile of fermented sausages. Sodium chloride (NaCl) is an essential ingredient in meat products,and it improves texture and decreases water activity, which guaranteesthe quality and safety of meat products (De Almeida et al., 2018).However, excessive sodium intake in the human diet may lead to hy-pertension and cardiovascular disease (Paik, Wendel, & Freeman,2005). The main source of sodium intake in diets are processed meatproducts, such as sausage, bacon and ham (Ruusunen & Puolanne,2005; Zhang et al., 2017). Especially, fermented sausages have thehighest levels of NaCl among meat products because of the dehydrationprocess undergone during their production (Campagnol, dos Santos,Wagner, Terra, & Mar, 2011, Desmond, 2006). Such as Salami, a typicaldry fermented sausage, its NaCl content reaches as high as 4.6%-4.8%on a wet weight (Desmond, 2006). The substitution of NaCl with potassium chloride (KCl) is widelyused to preserve the quality of meat products. KCl is considered to bethe best sodium substitute because it has a saltiness and an anti-microbial efficiency that is equivalent to NaCl (Bidlas & Lambert,2008). Besides, the intake of KCl is not correlated to hypertension andcardiovascular diseases (Buemi et al., 2002). However, a high level ofKCl (30%-40%) produces bitter and metallic tastes (dos Santos, Campagnol, Morgano, & Pollonio, 2014; Guardia, Guerrero, Gelabert,Gou, & Arnau, 2008; Morris et al., 2010). And increasing KCl levels infoods could increase risk of diabetes, chronic kidney disease, end stagerenal disease, severe heart failure and adrenal insufficiency (Van Buren,Dotsch-Klerk, Seewi, & Newson, 2016). The reported doses of KClcausing above adverse effects ranged from 1 to 94 g/day in adults andfrom 1.5 to 7 g/day in infants (Steffensen et al., 2018). To mask thedefects of KCl, flavour enhancers that improve taste and aroma, in-cluding glutamate, amino acids and citric acid, are used as sodiumsubstitutes (Campagnol, dos Santos, Morgano, Terra, & Pollonio, 2011;dos Santos et al., 2014). Our previous studies partially substituted NaClwith KCl combined with some enhancers and improved the sensoryfactors and texture of Harbin dry sausage (Chen et al., 2019). Thesubstitutes decreased the lipid and protein oxidation and promoted theflavour development in Harbin dry sausage (Wen et al., 2019). Theseflavour enhancers included lysine, maltodextrin, alanine, calcium lac-tate and citric acid, which mask the undesirable flavour of KCl andincrease the saline taste. Flavour is an important quality attribute for determining consumeracceptance and preference (Chen, Song, Bi, Meng, & Wu, 2018). Themicrobial community composition primarily affects the flavour devel-opment of fermented foods (Wu et al., 2015). Inoculation of the starter ( E-mail addresses: qinligang@neau. e du . cn ( L. Qin), k ongb h 63@hotmail.com ( B . Kong). ) ( https : / / doi.org / 10 . 1016/ j .me a tsci.2020 . 1083 3 8 ) ( Received 1 July 2020; Received i n revised f orm 3 October 2020; Accepted 6 O c t ober 2020 Available online 08 October 2020 ) ( 0309-1740/ C 2020 Elsevier Ltd . All rights re s erved. ) cultures shortens the fermentation time, inhibits the pathogenic orspoilage bacteria and improves the quality characteristics of the finalproducts. Our previous studies found that several bacterial strains iso-lated from Harbin dry sausage (Lactobacillus curvatus, Pediococcus pen-tosaceus and Staphylococcus xylosus) promoted the hydrolysis of lipidsand proteins to generate the precursors of flavour compounds or flavourcompounds, which contributed to the taste and aroma profile of drysausage (Chen, Kong, Han, Liu, & Xu, 2016; Chen, Kong,Han, Xia, & Xu,2017; Hu et al.,2019). Salt is a major factor that affects the growth ofbacteria. However, little is known about the effects of the sodiumsubstitutes on the flavour development of the dry sausage inoculatedwith these bacteria strains. Headspace solid phase micro-extraction gas chromatography-massspectrometry (HS-SPME-GC-MS) has been widely used recently toidentify the volatile compounds (Dong et al., 2018). Electronic nose (E-nose) and electronic tongue (E-tongue) are largely used in flavouranalysis (Peris & Escuder-Gilabert, 2016; Wasilewski, Migon, Gebicki, &Kamysz, 2019), and these devices are powerful tools to distinguishflavour profiles and characterize the differences in odour and taste offoods without subjective factors and judgements (Donglu et al., 2017;Zaragozá et al., 2013). Hence,HS-SPME-GC-MS combined with E-noseand E-tongue can be used to characterize the flavour profiles of dryfermented sausages with different sodium substitutes, which may pro-vide a reference for establishing more comprehensive rapid identifica-tion method by flavour characteristics of dry fermented sausage.Therefore, the present study investigated the effects of the sodiumsubstitute with flavour enhancers on the flavour profile of dry sausageinoculated with a mixed starter culture (L. curvatus, P. pentosaceus andS. xylosus), and the physical properties, bacterial counts and sensoryevaluation of dry fermented sausages were performed. 2. Materials and methods 2.1. Preparation of dry fermented sausages The dry fermented sausage was manufactured according to themethod of Hu et al. (2020). Lean pork (3600 g) and pork back fat(400 g) were minced through a 1.5-cm plate with the following in-gredients: NaCl (100 g), sodium nitrite (0.18 g), sodium ascorbate(0.20 g), dextrose (100 g), monosodium glutamate (6.0 g), wine(20.0 g) and mixed spices (6.0 g). The mixed spices contained roundcardamom, Pericarpium zanthoxyli, angelica, aniseed, fennel, Amomumvillosum, cassia bark, clove and pepper. The mixed starter culture(10’CFU/g sausage), including L. curvatus, P. pentosaceus R1 and s.xylosus A2, was used for the sausage preparation. P. pentosaceus R1 andS. xylosus A2 were isolated from Harbin dry sausages, and L. curvatuswas obtained from the China General Microbiological Culture Collec-tion Centre. Three independent batches of dry fermented sausages were pre-pared, and three sausage treatments were performed in each batch:control (100% NaCl), S1 (70% NaCl and 30% KCl) and S2 (70% NaCl,20% KCl, 4% lysine, 3.5% maltodextrin, 1% alanine, 1% calcium lactateand 0.5% citric acid). The meat batter was thoroughly mixed andstuffed into natural pig intestine casings (diameter 3.0 cm) to producesausages with final weights of approximately 0.15 kg. All batches ofsausages were air-dried at 25±2℃(30-50% relative humidity) for 1d and then stored at 25± 2℃(75% to 80% relative humidity) in awell-ventilated chamber for 8 d. The sausage samples in each treatmentwere randomly taken on days 0, 3, 6 and 9 to measure the physico-chemical properties, bacterial counts, and volatile compound contentsand perform E-nose, E-tongue, and sensory evaluations. 2.2. Physicochemical and bacterial analysis 90.0 mL distilled water, and the pH of the mixture was measured usinga pH metre (MettlerToledo Instruments Co., Ltd., Shanghai, China). LABcount was determined on de Man, Rogosa and Sharpe (MRS) agar in-oculated at 30℃ for 48 h. Staphylococcus count was measured onMannitol Salt Agar (MSA) inoculated at 32℃ for 17 h (Chen et al.,2019). 2.3. Volatile compound analysis The volatile compounds of dry fermented sausages were extractedusing HS-SPME and analysed using a GC-MS system (GCMS-QP2020NX, Shimadzu Corporation, Kyoto, Japan) according to the method ofWen et al. (2019). A total of 3.0 g minced sausages was placed in 20-mLheadspace sample vials. The volatile compounds were identified viacomparison of the experimental mass spectra with a mass spectra li-brary from NIST17 and/or via calculation of the retention index relativeto a series of standard alkanes (C6-C20) to calculate the linear retentionindex (LRI). The contents of the volatile compounds are expressed asug/kg. The contribution of each volatile compound to the overall odourwas evaluated as the odour activity value (OAV). The OAV was calcu-lated as the ratio of the content of each compound to its odour thresholdvalue in water (Olivares, Navarro, & Flores,2011). The odour thresholdvalues of volatile compounds were obtained from the Flavour-Base 10thEdition (http://www.leffingwell.com/flavbase.htm). 2.4. Electronic nose analysis According to the previous report of Wu, Yue, Xu, and Zhang (2017),the PEN3 portable E-nose (Airsense Analytics GmbH, Schwerin, Ger-many) equipped with 10 metal oxide semiconductor (MOS) sensors wasused for E-nose analysis. The information of each sensor is shown inTable 1. 2.5. Electronic tongue analysis E-tongue analysis was performed according to a previous method(Zhang et al.,2019) with some modifications. Briefly, 45.0 g of theminced dry sausage was mixed with 225.0 mL of distilled water toextract the taste substances. After the mixed solution was centrifuged2265 ×g for 10 min at 4℃, the water phase was obtained for E-tongueanalysis using a Taste Sensing System E-tongue (TS-5000Z, Insent Inc.,Japan), which was equipped with five chemical sensors for umami(AAE), astringency (AE1), saltiness (CTO), sourness (CA0) and bitter-ness (C00) and two reference electrodes. Table 1Information of 10 sensors for electronic nose. Sensor name Representative material Description(s) species W1C Aromatic Sensitive to aromatic constituents, benzene W5S Broad range Sensitive to nitrogen oxides W3C Aromatic Sensitive to aroma, ammonia W6S Hydrogen Sensitive to hydrides W5C Arom-aliph Sensitive to short-chain alkane aromatic component W1S Broad-methane Sensitive to methyl W1W Sulphur-organic Sensitive to sulphides W2S Broad-alcohol Sensitive to alcohols, aldehydes and ketones W2W Sulph-chlor Sensitive to organic sulphides W3S Methane-aliph Sensitive to long-chain alkanes Sensory evaluation of a nine-day dry fermented sausage was per-formed according to the method of Hu et al. (2020) with modifications.The sensory evaluation of the sausage samples was performed bytwenty qualified panellists (10 males and 10 females) with prior ex-perience in muscle food sensory tests who were selected from a pool offaculty, staff, and graduate students across 3 sessions. Training sessionswere carried out for panellists prior to sensory evaluation. During thetraining sessions, the panellists defined and developed sensory attri-butes of the samples until they reached an agreement with the attri-butes according to the objective of the present work (Zhan et al., 2019).The session was held 4 times per week for 2 weeks, with each trainingsession lasting for 2 h (Zhang et al., 2018). After training, the basicoperation of sensory evaluation and the quality standards of differentattributes must be mastered by panellists. A“warm-up”sample at thebeginning of each session was evaluated to acquaint panellists with thescoring system. Sausage slices (2-mm thick) were served randomly onwhite plastic plates coded with randomized 3-digit numbers. The sen-sory evaluation was determined based on a 7-point intensity scale from1 (low intensity) to 7 (high intensity): colour (1 = dark and dull;7 = red and shiny), odour (1 = light meat, spice and fermentationodour; 7 = strong meat, spice and fermentation odour), salty taste(1 =light salty taste; 7= strong salty taste), acid taste (1= light acidtaste; 7 = strong acid taste),bitter taste (1= non-bitter; 7 = extremelybitter) and overall acceptability (1= low;7=high). The panellistscleansed their mouths/taste buds with water between samples. Theevaluations were performed under normal light at room temperature(approximately 25C). 2.7. Statistical analysis Three independent batches of sausages (replicates) were preparedon different days, and a total of three treatments of sausages wereprepared in each batch. All experimental measurements were per-formed in triplicate (triplicate observations) for each batch of sausages.The results are expressed as the mean values ± standard errors (SE). Toanalyse the effects of factors and the interaction between factors (salttreatment and fermentation time), two-way analysis of variance(ANOVA) with Tukey's test was performed using Statistical software(version 5.0, StatSoft. Inc., Tulsa, USA) at the significance level of 0.05.Biplot based on principal component analysis (PCA) was performedusing the SIMCA software (version 14.1, Umea, Sweden) for volatilecompounds, E-nose and E-tongue data. The hierarchical cluster analysis(HCA) was performed using SPSS 22.0 (Analytical Software, New York,USA). Variations in moisture content, pH, LAB and Staphylococcuscounts, volatile compounds, E-nose and E-tongue were described usinga mixed model with different treatments (C, S1 and S2) and differentfermentation times (0, 3,6 and 9 d) as fixed terms, and sausage andpreparation day as random terms. For the analyses of factors affectingeach sensory trait (colour, aroma, salty taste, acid taste, bitter taste andoverall acceptability), a fixed term for full models included differenttreatments (C, S1 and S2) and random terms included sausage, pre-paration day and sensory panel (session number, tasting order andpanellist number). 3. Results and discussion 3.1. Moisture content, pH and bacterial counts As presented in Table 2, the moisture contents decreased from62.98%,62.78% and 61.99% at 0 d to28.87%,32.12%and 33.15%at 9d for the control, S1 and S2 treatments, respectively (P<0.05). Therewere higher moisture contents in the S1 and S2 treatments compared tothe control treatment (P <0.05), which was attributed to the lowerNat content that inhibited the release of water (Alino, Grau, Baigts, & Barat, 2009). The lower pH was determined in the S1 and S2 treatmentsthan the control treatment(P <0.05), which was primarily attributedto the higher LAB counts caused by the lowering of the NaCl additionlevel. Moreover, the pH of the S2 treatment was the lowest of all threetreatments (P <0.05) due to the use of amino acids (lysine and ala-nine), which are directly metabolized by the microorganisms (Chenet al., 2019). LAB and Staphylococcus are essential for developing theflavour and quality of fermented meats (Ravyts, De Vuyst, & Leroy,2012). The LAB count sharply increased from approximately 7.0 logCFU/g to 8.41,8.61 and 8.76log CFU/g (P <0.05) for the control, S1and S2 treatments, respectively, and the S1 and S2 treatments hadhigher LAB counts than the control treatment (P <0.05). As we know,the growth of Staphylococcus would be limited by the low pH and de-creased oxygen contents caused by LAB (Lisazo, Chasco, & Beriain,1999). However, the Staphylococcus count for the control, S1 and S2treatments slowly increased from approximately 7.0 log CFU/g to 7.88,7.64 and 7.62 log CFU/g after a nine-day fermentation, respectively(P<0.05). It is worth noting that the Staphylococcus xylosus A2 wasused as starter culture for the sausage preparation, and its inoculationlevel was approximately 7.0 log CFU/g. Therefore, the slight increase inStaphylococcus counts of sausages may be attributed to the high initialStaphylococcus counts. This result was consistent with the findings ofXiao, Liu, Chen, Xie, and Li (2020). Besides, the Staphylococcus countsin the S1 and S2 treatments were lower than the control treatment(P <0.05), which may be ascribed to the halophilism of Staphylo-coccus and the lower pH. 3.2. Volatile compound analysis 3.2.1. Volatile compound contents Sixty-two volatile compounds were detected in the dry fermentedsausages during fermentation and were comprised of 8 aldehydes, 4ketones, 12 alcohols, 5 acids, 12 esters, 18 terpenes and 3 others(Table 3). The compounds were generated via carbohydrate metabo-lism,lipid oxidation, amino acid catabolism, bacterial esterification andspices (round cardamom, Pericarpium zanthoxyli, angelica, aniseed,fennel, Amomum villosum, cassia bark, clove and pepper) (Chen et al.,2017; Flores, Corrala, Cano-Garciaa, Salvadora, & Bellochb, 2015). Carbohydrate metabolism has large effects on the flavour formationof fermented sausages, which is primarily performed by the LAB thatgenerated acids, alcohols and ketones (Ravyts et al., 2012). As shown inTable 3, there were significant differences (P < 0.05) not only infermentation time and NaCl level, but also in the interaction betweenthe fermentation time and NaCl level for the most compounds (exceptfor ethanol) derived from carbohydrate metabolism. The compoundsoriginated from carbohydrate metabolism, including ethanol, 3-hy-droxy-2-butanone, acetone, butanoic acid and acetic acid, were de-tected in all three treatments in the present. The contents of 3-hydroxy-2-butanone, which is a characteristic flavour compound with dairy andoverripe fruit odours, significantly increased (P < 0.05). While, thecontents of ethanol significantly decreased during fermentation(P <0.05), which may be because it is converted into the corre-sponding acids, aldehydes and esters (Sun, Zhao, Zhao, Zhao, & Yang,2010). Notably, the contents of acetic acid and butanoic acid increased,but this increase may not greatly affect the flavour development due totheir higher odour threshold values (Hu et al., 2020). As described byCorral, Salvador, and Flores (2013), a NaCl reduction affected thecompounds from carbohydrate metabolism. The S2 treatment had thehighest contents of these compounds in all three treatments in thepresent (P <0.05), which was ascribed to the lowest NaCl contents inthe S2 treatment and promoted LAB growth and metabolism (Chen, Liu,Sun, Kong, & Xiong, 2015). Lipid autoxidation and incomplete lipid p-oxidation promote freefatty acids and other precursors to form volatile compounds via che-mical and microbial reactions, respectively (Olivares, Navarro, &Flores, 2009). Most acids and aldehydes, such as octanoic acid, Table 2 Physicochemical and bacterial properties of dry fermented sausages with different NaCl substitutes during fermentation. Salt treatment Fermentation time Moisture content (%) pH Lactic acid bacteria count (log CFU/g) Staphylococcus count (log CFU/g) C 0d 62.98±0.52 6.42±0.12 6.99±0.23 7.01±0.13° Sl 62.78±0.19° 6.38±0.10 7.02±0.03 7.03±0.09° S2 61.99±0.79° 6.24±0.08 6.95±0.15 7.02±0.18 c 3d 45.19±0.55° 5.55±0.02 8.10±0.10° 7.59±0.07° si 43.16±0.90 5.15±0.03° 8.19±0.11cd 7.57±0.09 S2 49.45±0.43 4.87±0.10° 8.49 ±0.0gabc 7.60±0.12 6 d 36.95±0.30 5.03±0.03 8.24±0.06 7.90±0.04° 38.45±0.61' 4.87±0.04 8.46±0.12abc 7.75±0.0zabc S2 41.49±0.45° 4.53±0.02 8.69±0.05 7.70 ±0.06abc C 9 d 28.87±0.25" 4.96±0.05 8.41 ±0.07bcd 7.88±0.02ab Si 32.12±0.438 4.86±0.06 8.61±0.02 7.64 ±0.04abc S2 33.15±0.418 4.53±0.09° 8.76±0.04 7.62±0.03c P (Salt) ** ** P(Time) ** ** ★* ** P (Salt * Time) ** ** ** ns Data are represented as the mean values ± standard errors. a h Indicates within the same column with different lowercase letters significant differences (P <0.05).C: 100% NaCl; S1: 70% NaCl and 30% KCl; S2: 70% NaCl, 20% KCl and 10% flavour enhancers. ns: not significant (P > 0.05); *: important (P <0.05);**: veryimportant (P <0.01). hexanoic acid, nonanoic acid, octanal, hexanal and nonanal, commonlyoriginate from lipid autoxidation and play significant roles in the fla-vour development of fermented sausage (Cano-Garcia, Rivera-Jimenez,Belloch, & Flores, 2014; Chen et al., 2017). However, the contents ofthese compounds varied insignificantly in all three treatments(P > 0.05). Additionally, 2-nonanone originated from lipid B-oxida-tion due to the presence of Staphylococcus, which provides meat pro-ducts with rose and tea odours (Flores et al., 2015; Shahidi, Rubin, &D'Souza, 1986). Among the compounds from lipid oxidation, only thecontent of 2-nonanone was significantly influenced by fermentationtime, NaCl level and their interactions (P< 0.05).A lower content ofthis compound was found in the S2 treatment compared to the othertreatments at 9 d (P<0.05). Amino acid catabolism is also a major pathway for producing vo-latile compounds. (Herranz, Fernandez, de la Hoz, & Ordonez, 2006).The a-keto acids, which are the important intermediates of amino acidcatabolism, are metabolized to form the corresponding aldehydes, andthe aldehydes can also be converted into the corresponding alcoholsand acids, which may provide fruity, malty and sweaty odours in thefermented sausages (Hu et al., 2019). The present study demonstratedthat the contents of 2-methylbutanal, 2-methylpropanal and 3-methyl-butanal that are originated from the catabolism of isoleucine, valineand leucine via the action of LAB (Herranz et al., 2006; Irigoyen,Ortigosa, Juansaras, Oneca, & Torre, 2007) were significant influencedby the fermentation time and NaCl level as well as their interactions(P <0.05). The results showed that their contents were higher in theS2 treatment than the other treatments (P <0.05). Bacterial esterification of fatty acids with alcohols greatly affects theformation of esters that provide fruity and sweet odours and mask arancid odour (Cano-Garcia et al., 2014; Flores, Dura, Marco, & Toldra,2004; Stahnke, 1994). Ethyl esters (including ethyl acetate, ethyl lac-tate, ethyl hexanoate, ethyl heptanoate, ethyl octanoate, ethyl butyrate,ethyl decanoate and ethyl 3-phenylpropionate) were the most abundantesters in the fermented sausages in the present study, which may bederived from the esterification of ethanol and acids and directly fromthe wine used in sausage preparation (Carroll, Desai, & Atsumi, 2016).The lower contents of most esters were found in the S1 and S2 treat-ments compared to the control treatment (P <0.05), which may bedue to the esterification of Staphylococcus (Papamanoli, Kotzekidou,Tzanetakis, & Litopoulou-Tzanetaki, 2002; Purrinos, Franco, Carballo,& Lorenzo, 2012). Several studies reported that the terpenes, such as humulene, β-pinene, 3-carene, a-curcumene, D-limonene, copaene and y-terpinolene, may be derived from the spices (Montanari et al., 2016; Petricevic,Radovcic, Lukic, Listes, & Medic, 2018). An increased content of thesecompounds was found during fermentation in the present study(P <0.05), which may be due to the drying and subsequent con-centration of spices. While, the effects of NaCl level and the interactionbetween fermentation time and NaCl level on the contents of thesecompounds were not significant(P> 0.05). 3.2.2. Principal component analysis of volatile compounds To further highlight the differences of volatile profiles of dry fer-mented sausages with different sodium substitutes, PCA was performedon the volatile compounds of the sausages. The first two principlecomponents explained 97.00% and 1.90% of the overall variance, re-spectively (Fig. 1). The first principal component (PC1) was the mostimportant variable and positively correlated with all the volatile com-pounds except for ethano (13). A clear separation among sausages canbe observed. The sausages at 0 d were clustered in the negative PC1axis, while the sausages at 9 d were arranged on the positive PC1 axis,which indicated that PC1 differentiated sausages with respect to thefermentation. 3.2.3. Odour activity value analysis Flavour perception not only depends on the contents of volatilecompounds but is also associated with the threshold values of the vo-latile compounds (Van Gemert, 2011).OAV is an index combining thesetwo parameters to evaluate the contribution of volatile compounds(Olivares et al., 2009). It is generally recognized that compounds withan OAV > 1 play an important role in overall odour (Olivares et al.,2009). Compounds with OAV > 1 and their odour descriptions arelisted in Table 4. There were 26 key volatile compounds with OAV > 1,which were considered the main contributors to the fermented odour insausages during the whole fermentation. Compounds with OAV > 1and their odour descriptions are listed in Table 4. Compounds with anOAV >1 play an important role in overall odour (Olivares et al.,2009). There were 26 key volatile compounds with OAV> 1, whichwere considered the main contributors to the fermented odour in sau-sages during the whole fermentation. Particularly, 2-methylpropanal, 2-methylbutanal, octanal, nonanal, hexanal, hexanol, 1-octen-3-ol, eu-calyptol, linalool, methyl butyrate, methyl hexanoate, ethyl acetate,ethyl hexanoate, ethyl heptanoate, ethyl butyrate, ethyl 3-phenylpro-pionate, copaene, B-caryophyllene and p-limonene (with OAV > 5)greatly contributed to the overall odour of dry fermented sausages. Forexample, the compound with the highest OAV (OAV=108.03-865.54) oo 台白*寸erONn8寸: Na 80+寸1 O¥+1+1+1 70+I.+ +I+ + 00981+ 1 +1 7 = O寸 - H0 O8N 寸 nm 寸 e eOa 寸w寸 3 8 6ON N 9 a+1 +十81品+1 + +1 + OOmm寸6:8O + z9 M8 ○N 1+1寸0 寸 寸9 寸 寸 寸 寸 6寸N 寸 N 寸e寸N 寸寸 寸 +1++\ + s + 1 + \ +1 +1 e寸O 寸8 寸O寸 O 一9 N 6 6 8 寸寸 mS 1 .q a o9 寸60 08 9+1+++I 0 0+1+O8!+0 + +1 +11 8 + + +1 +0 N 寸 96 =. 0N 寸寸I 寸 寸 0 IN 6 6 8 oA 6 ,9a O a8 9 O++1 9T0 +N]cN O + + ¥+ 99 O¥ o8 9 寸 86 T N NN 8 6 S t7 6 o 1 9 a 6qa 8 O二9 4 0+1H+ +1+ +1+ O +1+11 7 ++1 +1 8 1 +662 N Nm LL 寸 Nn68 7NNIT T6 寸 N M寸寸ON寸ON wwwwwwwwa aana aa aaa a a n a ooaoaoo ow'oO 导 导品贸品贸路品858 oooooooo八moz in all sausages was ethyl hexanoate, which contributed apple peel andfruity odourstito thesausages. D-limonene vwith ahigh OAV(OAV = 71.15-99.66) is a major component of the pepper that wasadded during the preparation of sausage, which contributed to thelemon note of the dry fermented sausages (Wilkins & Madsen, 1989). 3.3. Electronic nose analysis As depicted in Fig. 2B, PC1 and PC2 explained 75.50% and 13.90%of the total variance, respectively. PC1 was the most important variablefor the differences between treatments (control, S1 and S2). All sau-sages at 0 d clustered in the negative axis of PC1, which were correlatedto the sensors of W6S, W3S and W5S, and all sausages at 9 d clustered inthe positive axis of PC1, which were associated with the other sensors.The results showed that these sensors more effectively discriminateddry fermented sausages with different fermentation times. The E-nosedata distribution of the S1 and S2 treatments was relatively close, in-dicating that they had similar odours. 3.4. Electronic tongue analysis As presented in Fig. 3A, the response values of the sourness, salti-ness,bitterness,astringency, aftertaste-astringency (aftertaste-A),aftertaste-bitterness (aftertaste-B) and richness increased (P< 0.05),and the response value of umami decreased (P < 0.05) in the fer-mented sausage from 0 d to 9 d. The increase in sourness may be causedby the generation of acids derived from the carbohydrate metabolism ofLAB. The S2 treatment had the highest sourness value of all the treat-ments at 9 d, which was consistent with the pH results. The increase inbitterness may be due to the addition of KCl and the decrease inmoisture content. Especially, the highest bitterness value was found inthe S1 treatment. The increase in saltiness may be attributed to thedecrease in moisture content, which caused the salt content to increase.Besides, the increase in richness after a nine-day fermentation may beexplained by the formation of various taste substances, such as freeamino acids, which may be produced from protein hydrolysis (Zhao,Schieber, & Ganzle,2016). As shown in Fig. 3B, PC1 and PC2 explained 82.00% and 14.60% ofthe total variance, respectively. All sausages at 0 d clustered in thenegative axis of PC1, which was associated with umami. All sausages at9 d clustered in the positive axis of PC1, which was related to the othertaste sensors. The control treatment was close to the S2 treatment,which may be resulted from the similarity of saltiness, sourness, as-tringency, aftertaste-A and the richness of these flavours. However, theS1 treatment was far from the S2 and control treatments due to thedifferences of bitterness and aftertaste-B. The results also indicated thatthe E-tongue well discriminated the S1 and S2 treatments that were notdistinguished by the E-nose (Fig. 2). R2X[1]=0.970 R2X[2]=0.019 3.5. Hierarchical cluster analysis of dry fermented sausages In order to characterize the correlation of dry fermented sausageswith different sodium substitutes, HCA was applied to the fused datasetcomprised of E-nose, E-tongue and key volatile compounds, employingthe Euclidean distances to calculate the interpoint distances among dryfermented sausages with different sodium substitutes (Zhu et al., 2020).As shown in Fig. 4, the dendrogram clearly showed that the sausageswere clustered into two major groups, including group A consisting ofthree sausages (C, S1 and S2 treatments at 0 d) and group B consistingof three sausages (C, S1 and S2 treatments at 9 d).The three sausages at0 d had the similar flavour profile, whereas the S1 treatment was most similar as the S2 treatment at 9 d. This result was similar as the PCAresults of volatile compounds and E-nose. That is say, the sodium sub-stitute had a more significant effect on the odour profile of dry fer-mented sausages. 3.6. Sensory evaluation As presented in Table 5, the sensory evaluation showed that thecolour and salty taste varied insignificantly in all the treatments(P> 0.05), which indicates that both sodium substitutes provided asimilar colour and salty taste as the control treatment. However, the S1treatment had the highest score of all treatments for bitter taste, which Table 4Odour activity values of key volatile compounds of dry fermented sausages with different NaCl substitutes at 0 d and 9 d. Volatile compounds Odour description(s) Odour threshold (ug/kg in water) 0d 9d C S1 S2 C S1 S2 Nonanal Fat, citrus, green 1 5.02 5.66 4.38 41.85 40.43 40.65 Octanal Fat, soap, lemon, green 0.7 2.51 2.83 2.20 36.63 36.67 36.30 Hexanal Grass, tallow, fat 5 2.97 3.20 2.73 12.32 12.61 12.44 2-Methylpropanal Malty 0.1 <1 <1 <1 23.00 26.20 33.40 2-Methylbutanal Almond, cheese, chocolate, malt 0.1 <1 <1 <1 26.40 27.80 37.40 3-Methylbutanal Almond, burnt, choking, cocoa 1.2 <1 < 1 <1 1.52 1.65 2.11 2-Nonanone Rose, tea 5 <1 <1 <1 2.48 2.34 1.85 3-Hydroxy-2-butanone Dairy, over ripe fruit 55 <1 < 1 < 1 1.55 1.62 1.67 Hexanol Resin, flower, green 2.5 2.17 2.38 1.96 7.04 7.12 7.76 1-Octen-3-ol Mushroom-like 1 3.24 4.02 2.46 18.71 18.11 18.17 Eucalyptol Strong camphor, fresh 12 13.41 13.54 13.29 43.54 43.32 42.63 Linalool Flower, citrus, orange, terpene, waxy, rose 6 33.82 34.01 33.63 76.39 73.95 74.85 Methyl butyrate Fruity 15.1 <1 <1 <1 2.70 2.48 2.47 Methyl hexanoate Fruity, fresh, sweet 70 <1 <1 <1 6.44 6.38 5.96 Methyl heptanoate Fruity 4 1.65 1.78 1.51 4.80 4.86 4.22 Ethyl acetate Solvent, pineapple, fruity, apples 5 2.64 2.78 2.50 13.91 12.29 11.91 Ethyl hexanoate Apple peel, fruity 1 115.40 122.77 108.03 865.54 666.11 637.01 Ethyl heptanoate Pineapple, fruity 2 2.62 2.82 2.42 9.37 9.06 8.74 Ethyl butyrate Apple 1 1.35 1.71 0.99 40.48 37.38 35.24 Ethyl3-Phenylpropionate Fruity, floral, sweet 1.6 1.02 1.27 <1 19.09 16.23 14.91 Copaene Wood, spice 6 10.90 12.03 9.78 26.60 26.16 25.08 Caryophyllene Wood, spice 64 1.45 1.49 1.41 2.69 2.63 2.55 B-Caryophyllene Wood, spice 64 1.19 1.09 1.18 2.53 2.40 2.45 Styrene Balsamic, gasoline 44 <1 <1 <1 1.17 1.09 1.08 D-Limonene Lemon 10 72.02 71.15 71.60 99.66 98.48 96.82 B-Pinene Pine, resin, turpentine 140 < 1 <1 <1 1.90 1.83 1.84 W1C R2X[1]=0.755 R2X[2]=0.139 Fig.2. Radar chart (A) and principal component analysis (B) of electronic nose data for dry fermented sausages with different NaCl substitutes at 0 d and 9 d. C:100% NaCl; S1: 70% NaCl and 30% KCl; S2: 70% NaCl, 20% KCl and 10% flavour enhancers. R2X[1]=0.820 R2X[2]=0.146 Fig. 3. Radar chart (A) and principal component analysis (B) of electronic tongue data for dry fermented sausages with different NaCl substitutes at 0 d and 9 d. C:100% NaCl; S1: 70% NaCl and 30% KCl; S2: 70% NaCl, 20% KCl and 10% flavour enhancers. Fig. 4. Hierarchical cluster analysis of dry fermented sausages with differentNaCl substitutes at 0 dand 9 d based on the electronic nose, electronic tongue,and key volatile compound data. C:100% NaCl; S1: 70% NaCl and 30% KCl; S2:70% NaCl, 20% KCl and 10% flavour enhancers. Table 5Sensory analysis of dry fermented sausages with different NaCl substitutes aftera nine-day fermentation. Attributes C S1 S2 Colour 5.75±0.30° 6.01±0.35 5.94±0.49 Odour 4.68±0.08 5.32±0.08 5.34±0.14 Salty taste 5.39±0.34 5.31±0.15° 5.19±0.29 Acid taste 5.43±0.07 5.39±0.16° 5.96±0.10 Bitter taste 3.52±0.11” 4.26±0.16 3.76±0.25” Overall acceptability 5.63±0.17 4.86±0.19° 5.49±0.26° The sensory attributes were evaluated on a scale from 1 to 7. The results arerepresented as the mean values ± standard errors. ab Indicates within the samerow with different lowercase letters significant differences (P < 0.05).C: 100% NaCl; S1: 70% NaCl and 30% KCl; S2: 70% NaCl, 20% KCl and 10%flavour enhancers. Acknowledgements This study was funded by the National Natural Science Foundationof China (31972139), the “Young Talents” Project of NortheastAgricultural University (18QC56) and the National Key Research andDevelopment Program during the 13th Five-year Plan period in China(2016YFD0401504-03). The volatile compound analysis was supportedby Shimadzu (China) Co., Ltd. In the Shenyang analytical centre. References Carroll, A. L., Desai, S. H., & Atsumi, S. (2016). Microbial production of scent and flavorcompounds. Current Opinion in Biotechnology, 37, 8-15. Chen, J. X., Hu, Y. Y., Wen, R. X., Liu, Q., Chen, Q., & Kong, B. H. (2019). Effect of NaClsubstitutes on the physical, microbial and sensory characteristics of Harbin drysausage. Meat Science, 156, 205-213. Chen, Q., Kong, B., Han, Q., Liu, Q., & Xu, L. (2016). The role of bacterial fermentation inthe hydrolysis and oxidation of sarcoplasmic and myofibrillar proteins in Harbin drysausages. Meat Science, 121, 196-206. Chen, Q.,Kong, B., Han, Q., Xia, X., & Xu, L. (2017). The role of bacterial fermentation inlipolysis and lipid oxidation in Harbin dry sausages and its flavour development.LWT-Food Science and Technology, 77, 389-396. Chen, Q., Liu, Q., Sun, Q., Kong, B.,& Xiong, Y. (2015). Flavour formation from hydro-lysis of pork sarcoplasmic protein extract by a unique LAB culture isolated fromHarbin dry sausage. Meat Science, 100, 110-117. Chen, Q., Song, J., Bi, J., Meng, X., & Wu, x. (2018). Characterization of volatile profilefrom ten different varieties of Chinese jujubes by HS-SPME/GC-MS coupled with E-nose. Food Research International, 105, 605-615. Corral,S., Salvador, A., & Flores, M. (2013). Salt reduction in slow fermented sausagesaffects the generation of aroma active compounds. Meat Science, 93, 776-785. De Almeida, M. A., Saldana,E., da Silva Pinto, J. S., Palacios, J., Contreras-Castillo, C. J., Sentandreu, M. A., & Fadda, S. G. (2018). A peptidomic approach of meat proteindegradation in a low-sodium fermented sausage model using autochthonous startercultures. Food Research International, 109, 368-379. Desmond, E. (2006). Reducing salt: A challenge for the meat industry. Meat Science,74,188-196. Dong, W. J., Hu, R. S., Long, Y. Z., Li, H. H., Zhang, Y. J., Zhu, K. X., & Chu, Z. (2018).8,Comparative evaluation of the volatile profiles and taste properties of roasted coffeebeans as affected by drying method and detected by electronic nose, electronictongue, and HS-SPME-GC-MS. Food Chemistry, 272, 723-731. Donglu, F., Wenjian, Y., Kimatu, B. M., Liyan, Z., Xinxin, A., & Qiuhui, H. (2017).Comparison of flavour qualities of mushrooms (Flammulina velutipes) packed withdifferent packaging materials. Food Chemistry, 232, 1-9. dos Santos, B. A., Campagnol, P. C., Morgano, M. A., & Pollonio, M. A. (2014). Monosodium glutamate, disodium inosinate, disodium guanylate, lysine and taurineimprove the sensory quality of fermented cooked sausages with 50% and 75% re-placement of NaCl with KCl.Meat Science,96, 509-513. Flores, M., Corrala, S., Cano-Garciaa, L., Salvadora, A., & Bellochb, C.(2015). Yeaststrains as potential aroma enhancers in dry fermented sausages. International Journalof Food Microbiology, 212, 16-24. Flores, M., Dura, M. A., Marco,A., & Toldra, F. (2004). Effect of Debaryomyces spp. onaroma formation and sensory quality of dry-fermented sausages. Meat Science, 68,439-446. Gou, P., Guerrero, L., Gelabert, J.,& Arnau, J. (1996). Potassium chloride, potassiumlactate and glycine as sodium chloride substitutes in fermented sausages and in dry-cured pork loin. Meat Science, 42(1), 37-48. Guardia, M. D., Guerrero, L., Gelabert, J., Gou, P., & Arnau, J. (2008). Sensory char-acterisation and consumer acceptability of small calibre fermented sausages with50%substitution of NaCl by mixtures of KCl and potassium lactate. Meat Science, 80,1225-1230. Herranz, B., Fernandez, M., de la Hoz, L., & Ordonez, J. A. (2006). Use of bacterial ex-tracts to enhance amino acid breakdown in dry fermented sausages. Meat Science, 72,318-325. Hu, Y. Y., Chen, Q., Wen, R. X., Wang,Y., Qin, L. G., & Kong, B. H. (2019). Qualitycharacteristics and flavor profile of Harbin dry sausages inoculated with lactic acidbacteria and Staphylococcus xylosus. LWT-Food Science and Technology, 114, Article108392. Hu, Y. Y., Zhang, L., Zhang, H., Wang, Y., Chen, Q., & Kong, B. H. (2020).Physicochemical properties and flavour profile of fermented dry sausages with areduction of sodium chloride.LWT-Food Science and Technology, 124, Article 109061. Irigoyen, A., Ortigosa, M., Juansaras, I., Oneca, M., & Torre, P. (2007). Influence of anadjunct culture of Lactobacillus on the free amino acids and volatile compounds in aRoncal-type ewe's-milk cheese. Food Chemistry, 100, 71-80. Lisazo, G., Chasco, J., & Beriain, M. J. (1999). Microbiological and biochemical changesduring ripening of salchichon, a Spanish dry cured sausage.Food Microbiology, 16,219-228. Montanari, C., Bargossi E., Gardini, A., Lanciotti, R., Magnani, R., Gardini, F., &Tabanelli, G. (2016). Correlation between volatile profiles of Italian fermented sau-sages and their size and starter culture. Food Chemistry, 192, 736-744. Morris, C., Labarre, C., Koliandris, A. L., Hewson, L., Wolf, B., Taylor, A. J., & Hort, J.(2010). Effect of pulsed delivery and bouillon base on saltiness and bitterness per-ceptions of salt delivery profiles partially substituted with KCl. Food Quality andPreference, 21,489-494. Olivares, A., Navarro, J. L., & Flores, M. (2009). Establishment of the contribution ofvolatile compounds to the aroma of fermented sausages at different stages of pro-cessing and storage. Food Chemistry, 115, 1464-1472. ( O liva r e s , A . , N avar ro , J. L . , & F l o res, M . ( 201 1 ) . E f fect o f f a t content on a roma ge ne rat i on d uri ng p r o c es si n g o f d r y f e r men t e d s a usage s. M e at Scie n ce, 8 7, 2 6 4-2 7 3 . ) Paik, D. C., Wendel, T. D., & Freeman, H. P. (2005). Cured meat consumption and hy-pertension: Analysis from NHANES ⅢI (1988-94). Nutrition Research, 25, 1049-1060. Papamanoli,E., Kotzekidou, P., Tzanetakis, N., & Litopoulou-Tzanetaki, E. (2002). Characterization of Micrococcaceae isolated from dry fermented sausage. FoodMicrobiology, 19,441-449. Peris, M., & Escuder-Gilabert, L. (2016). Electronic noses and tongues to access food ( a u then t ication a n d a d u l t er a tion. T r ends in F ood Scie n ce and T ec h nology, 58, 4 0- 5 4 . P etr i c evic, S ., R a d ovcic , N . M . , L uki c , K . , L i s tes , E. , & M e d i c , H . ( 20 1 8) . Di f fer e nti a t i on of ) dry-cured hams from different processing methods by means of volatile compounds,physico-chemical and sensory analysis. Meat Science, 137,217-227. Purrinos, L., Franco,D., Carballo, J., & Lorenzo, J. M. (2012). Influence of the salting timeon volatile compounds during the manufacture of dry-cured pork shoulder“lacon”.Meat Science, 92, 627-634. Ravyts, F., De Vuyst, L., & Leroy,F. (2012). Bacterial diversity and functionalities in foodfermentations. Engineering in Life Science, 12, 356-367. Ruusunen, M., & Puolanne, E. (2005). Reducing sodium intake from meat products. MeatScience, 70,531-541. Shahidi, F., Rubin, L. J., & D’Souza, L. A. (1986). Meat flavor volatiles: A review of thecomposition, techniques of analysis, and sensory evaluation. Critical Reviews in FoodScience and Nutrition, 20, 144-243. Stahnke, L. H. (1994). Aroma components from dried sausages fermented withStaphylococcus xylosus. Meat Science, 38, 39-53. Steffensen, I. L., Frolich, W., Dahl, K. H., Iversen, P. O.,Lyche, J. L., Lillegaard, I. T. L., &Alexander, J. (2018). Benefit and risk assessment of increasing potassium intake byreplacement of sodium chloride with potassium chloride in industrial food productsin Norway. Food and Chemical Toxicology, 111, 329-340. Sun, W. Z., Zhao, Q. Z., Zhao, H. F., Zhao, M. M., & Yang, B. (2010). Volatile compoundsof Cantonese sausage released at different stages of processing and storage. FoodChemistry, 121,319-325. ( T i g gemann, L. , Ba l len, S . C . , B o calon, C. M . , G r a boski, A . M . , M an z o l i, A ., S t ef f e ns, J . ,. . . S te f fe n s, C . ( 2 01 7 ) . E l ectronic n o se s y s t em b as ed o n p o l ya n i li ne fi l m s se n s o r a rr a y w ith d iffe r e n t d opants f o r d is c r im inat i on of a r ti f i ci al a r o ma s . I nnov a tive F ood S c ien c e a nd E mer g ing Technologie s , 4 3 , 1 1 2 -11 6. ) Van Buren, L., Dotsch-Klerk, M., Seewi, G., & Newson, R. (2016). Dietary impact ofadding potassium chloride to foods as a sodium reduction technique. Nutrients, 8(4),235. Van Gemert, L. J. (2011). Compilations of odour threshold values in air, water and othermedia (2011 ed.). The Netherlands: Oliemans Punter & Partners BV. Wasilewski, T., Migon, D., Gebicki, J., & Kamysz, W. (2019). Critical review of electronicnose and tongue instruments prospects in pharmaceutical analysis. Analytica ChimicaActa, 1077,14-29. Wen, R. X., Hu, Y. Y., Zhang, L., Wang, Y., Chen, Q., & Kong, B. H. (2019). Effect of NaClsubstitutes on lipid and protein oxidation and flavor development of Harbin dry ( s ausage. M eat S cience, 156, 33- 4 3. ) Wilkins, K., & Madsen, J. O. (1989). Paprika headspace constituents. Flavors and off-flavors. In G. Charalambous (Ed.). Proceedings of 6th international flavor conference(pp. 293-297). Amsterdam: Elsevier Science Publishers. Wu, R. N., Yu,M. L., Liu, X. Y., Meng, L. S., Wang, Q. Q., Xue, Y. T.,... Yue, X. Q(2015).Changes in flavour and microbial diversity during natural fermentation of suan-cai, atraditional food made in Northeast China. International Journal of Food Microbiology,211, 23-31. Wu, H., Yue, T. L., Xu, Z. J., & Zhang, C. (2017). Sensor Array optimization and dis-crimination of apple juices according to variety by electronic nose. AnalyticalMethods, 9, 921-928. Xiao, Y., Liu, Y., Chen, C., Xie, T.,& Li, P. (2020). Effect of Lactobacillus plantarum andStaphylococcus xylosus on flavour development and bacterial communities in Chinesedry fermented sausages. Food Research International, 135, Article 109247. Zaragoza, P., Fuentes, A., Fernandez-Segovia, I., Vivancos, J.L., Rizo, A., Ros-Lis, J. V., ...Martinez-Manez, R. (2013). Evaluation of sea bream (Sparus aurata) shelf life usingan optoelectronic nose. Food Chemistry, 138, 1374-1380. Zhan, H., Hayat, K., Cui, H. P., Hussain, S., Ho, C. T., & Zhang, X. M. (2019).Characterization of flavor active non-volatile compounds in chicken broth and cor-related contributing constituent compounds in muscle through sensory evaluationand partial least square regression analysis. LWT-Food Science and Technology, 118,Article 108786. Zhang, M., Chen, X., Hayat, K., Duhoranimana,E., Zhang, X. M., Xia, S. Q., ... Xing, F. L.(2018). Characterization of odor-active compounds of chicken broth and improvedflavor by thermal modulation in electrical stewpots. Food Research International, 109,72-81. Zhang, W., Naveena, B. M., Jo, C., Sakata, R., Zhou, G., Banerjee, R., & Nishiumi, T.(2017).Technological demands of meat processing-an Asian perspective. MeatScience,132, 35-44. Zhao, C. J.,Schieber, A., & Ganzle, M.G. (2016). Formation of taste-active amino acids,amino acid derivatives and peptides in food fermentations -a review. Food ResearchInternational, 89, 39-47. Zhu, D. S., Ren, X. J., Wei, L. W., Cao, X. H., Ge, Y. H., Liu, H., & Li, J. R. (2020).Collaborative analysis on difference of apple fruits flavour using electronic nose andelectronic tongue. Scientia Horticulturae, 260,108879. 摘要:研究了不同钠代物对干发酵香肠物理性质、风味特性和感官评价的影响。试验采用3种不同的盐配方,分别为对照(C:100%NaCl)、S1(70%NaCl+30%KCl)和S2(70%NaCl+20%KCl+10%风味增强剂),与对照相比,NaCl替代处理的水分含量和乳酸菌数量增加,pH值和葡萄球菌数量降低(p﹤0.05)。在香肠中检测到62种挥发性物质,根据气味活性值确定26种化合物为关键挥发性物质。电子舌实验结果和感官评价结果表明,S2处理的味觉轮廓与对照处理相似;而电子鼻、挥发性化合物结果和分级聚类分析表明,钠替代品对气味剖面的影响更为显著。总的来说,S2是一种理想的低钠替代品,可以减少30%的NaCl,并为发酵香肠提供更好的风味。关键词:钠替代品;风味增强剂;干发酵香肠;风味剖面;电子鼻;电子舌

确定

还剩8页未读,是否继续阅读?

产品配置单

北京盈盛恒泰科技有限责任公司为您提供《干发酵香肠中风味检测方案(感官智能分析)》,该方案主要用于熟肉制品中理化分析检测,参考标准--,《干发酵香肠中风味检测方案(感官智能分析)》用到的仪器有电子舌、日本INSENT味觉分析系统(电子舌)

相关方案

更多

该厂商其他方案

更多