方案详情

文

番茄酱是最常食用的调味品之一,由新鲜番茄或浓缩番茄泥和番茄酱制成。在番茄酱中加入香料和调味料,使其具有独特的风味。按照相关食品安全规定,食用胶体和淀粉也可以用作保水剂和增稠剂。虽然玉米淀粉因其成本低而通常是首选,但它可能会导致一些质量问题,如回生。因此,越来越多的研究都聚焦在将食用胶体加入番茄酱产品中,在番茄酱生产中使用食用胶体,可以得到较高的稠度和稳定性。然而,值得注意的是,某些国家不允许在番茄酱中使用非番茄基增稠剂,如淀粉和食用胶体。此外,消费者倾向于选择加入更少添加剂的食品。然而,另一种提高番茄酱稠度的方法是用均质技术对产品进一步加工。一般来说,在工业中采用两段均质化方法生产质地细腻的番茄酱产品。它通过分解番茄纤维来提高番茄酱的整体质量,降低平均粒径。微射流作为一种新型的均匀化技术正在得到广泛的应用,该技术作为一种新型的牛奶均质技术,在食品加工中得到了应用。大量研究表明,微射流处理的乳液和悬浮液具有一些独特的结构变化,进而影响整体产品特性。Behic Merit 利用LUMiSizer对微射流处理的番茄酱产品稳定性进行了相关测试研究。

方案详情

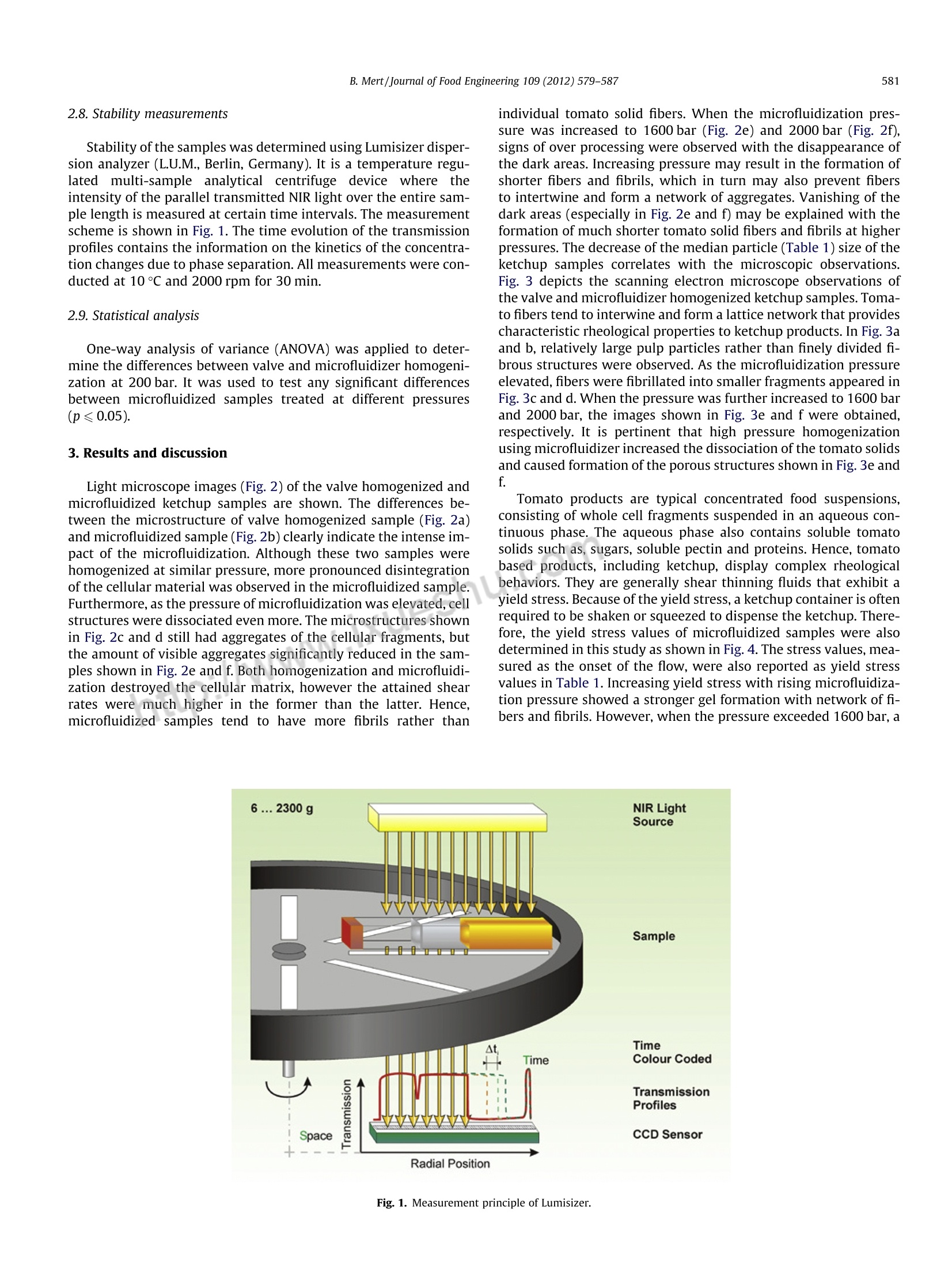

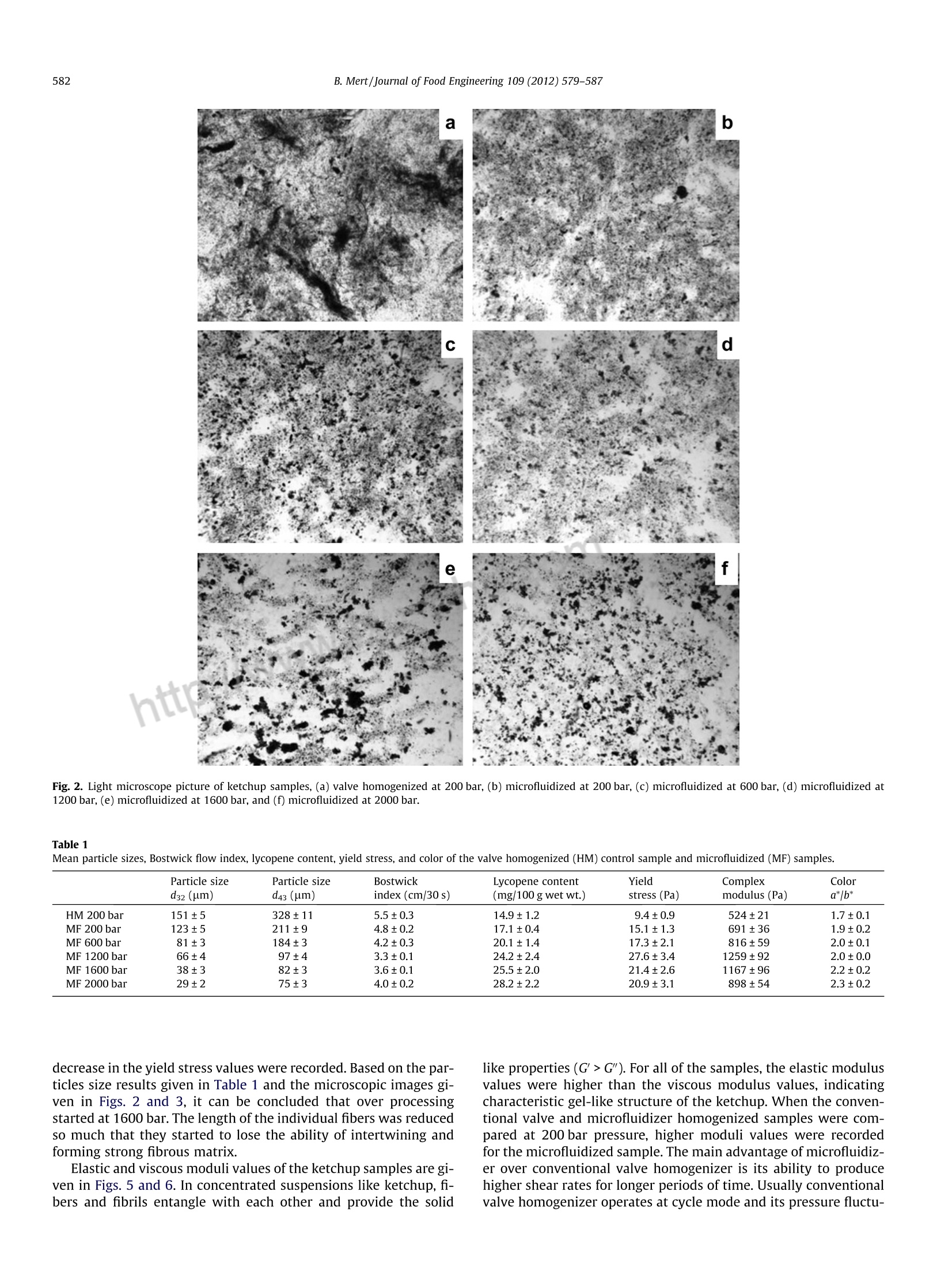

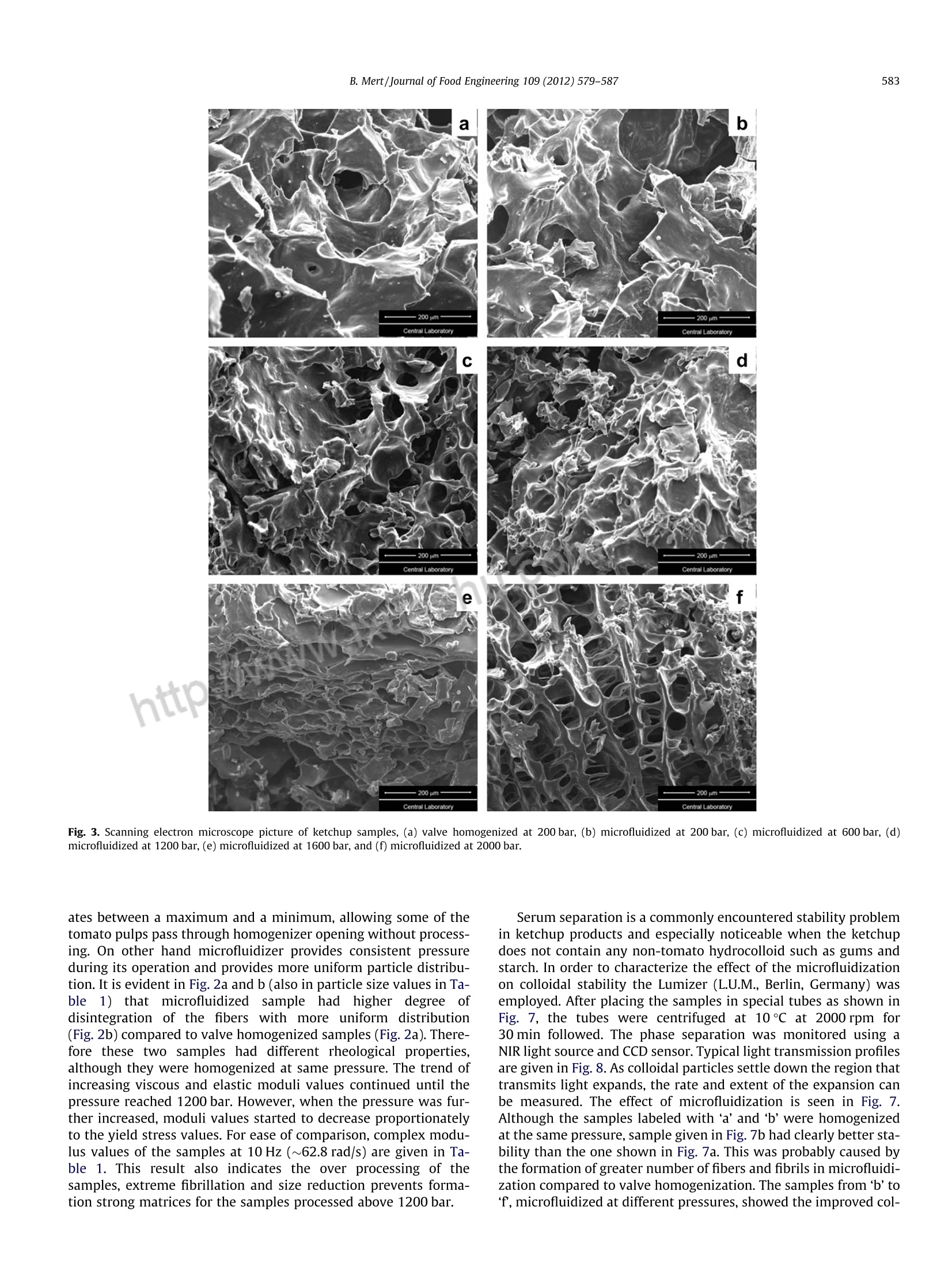

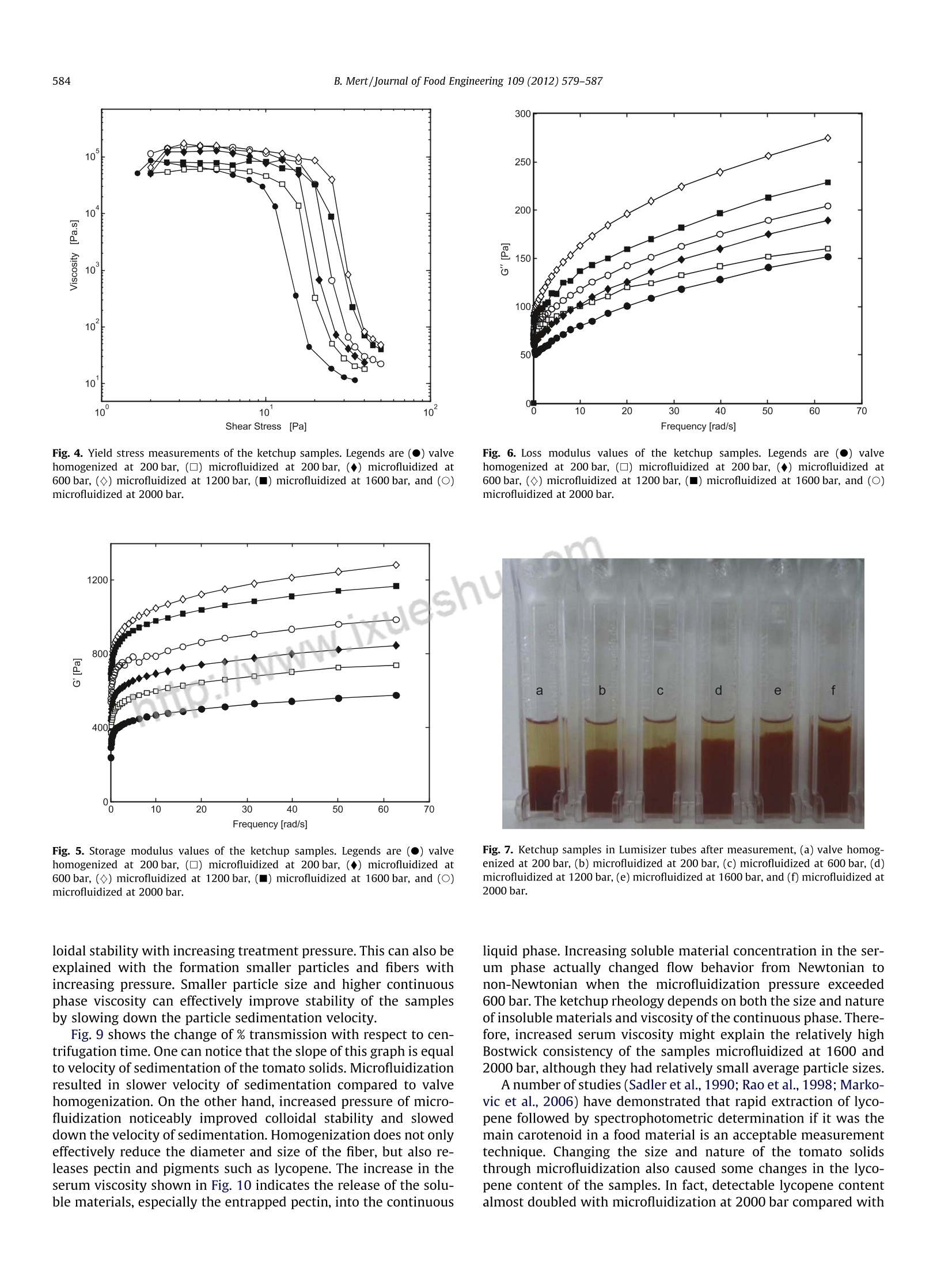

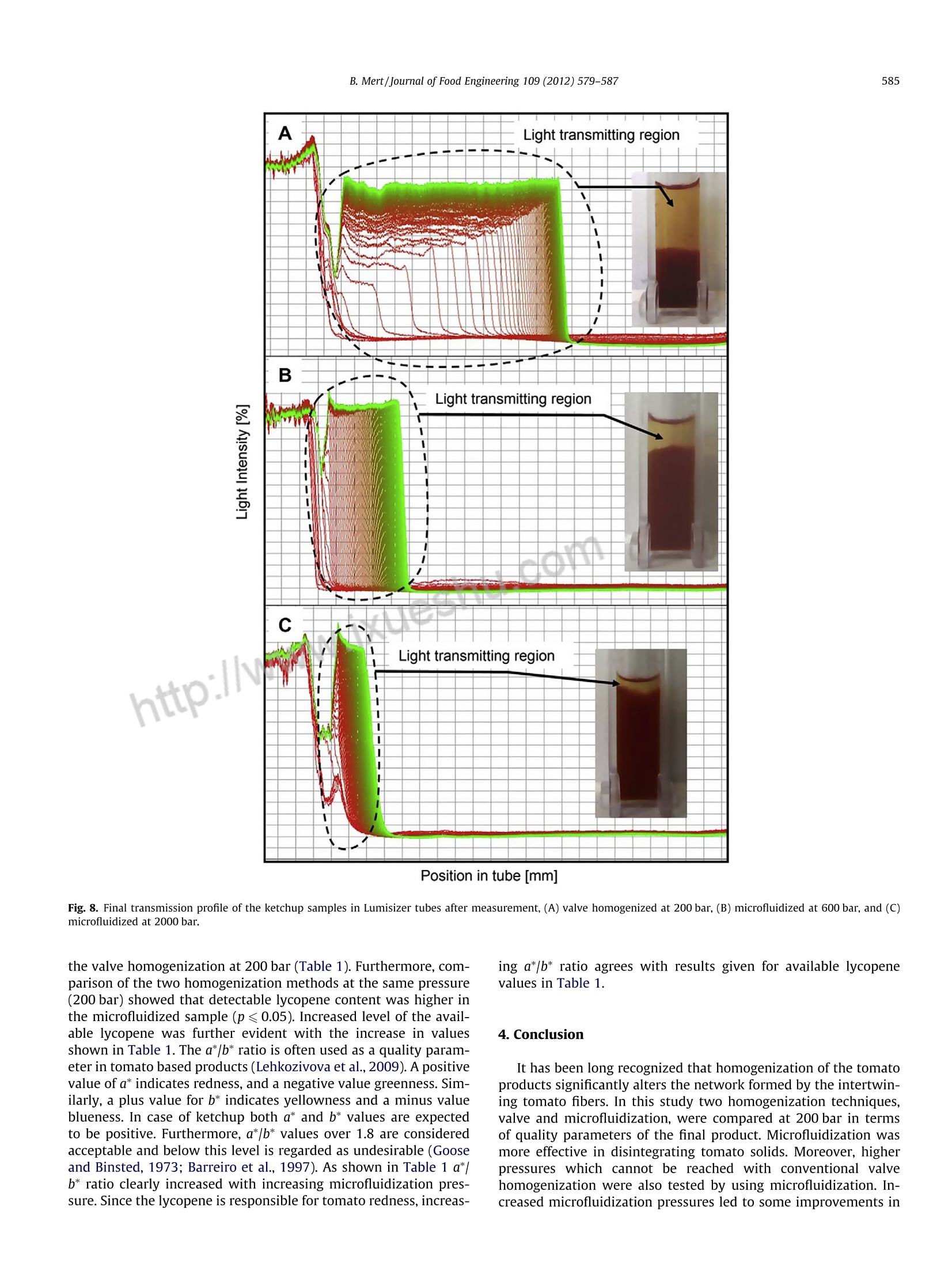

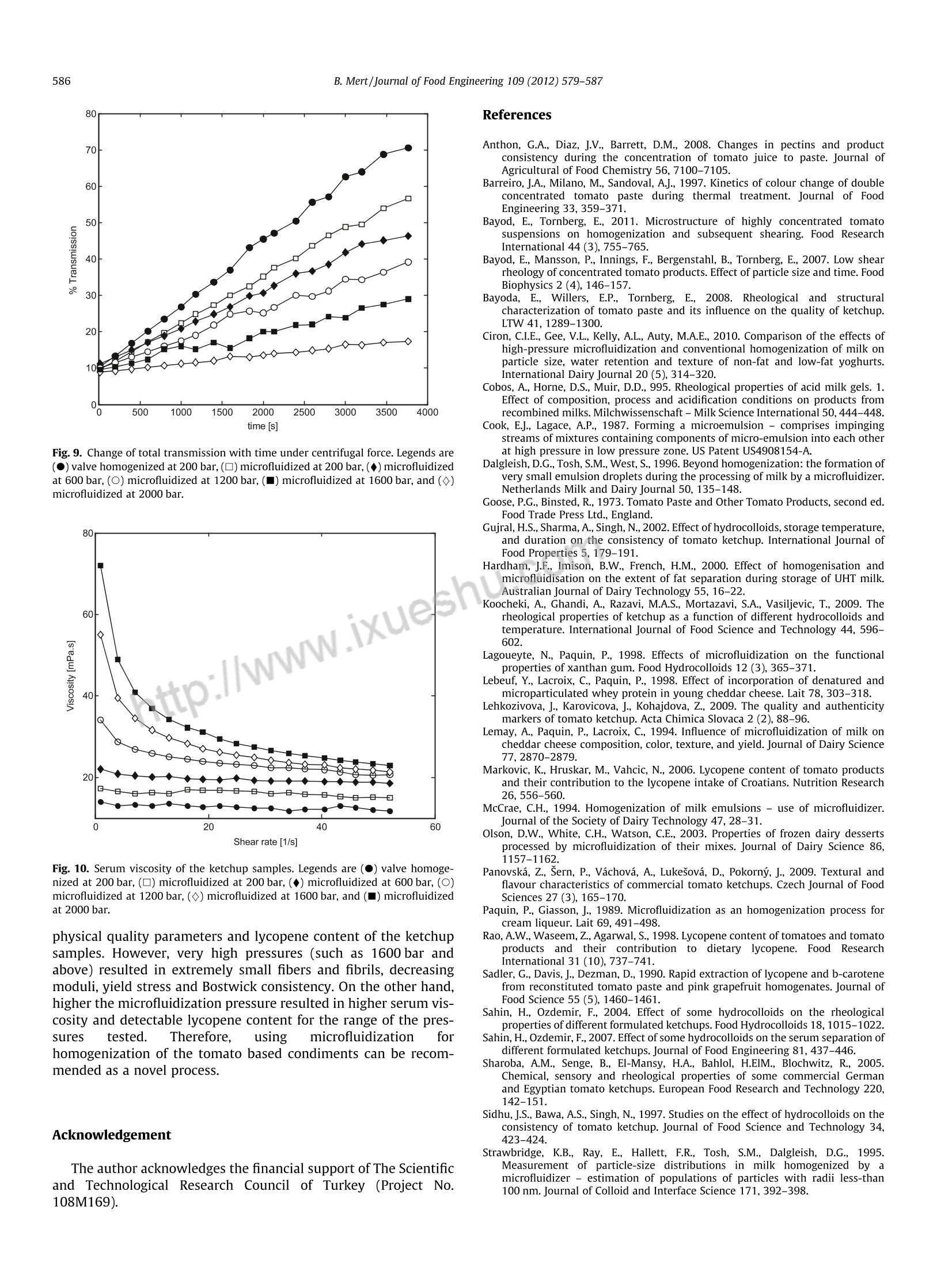

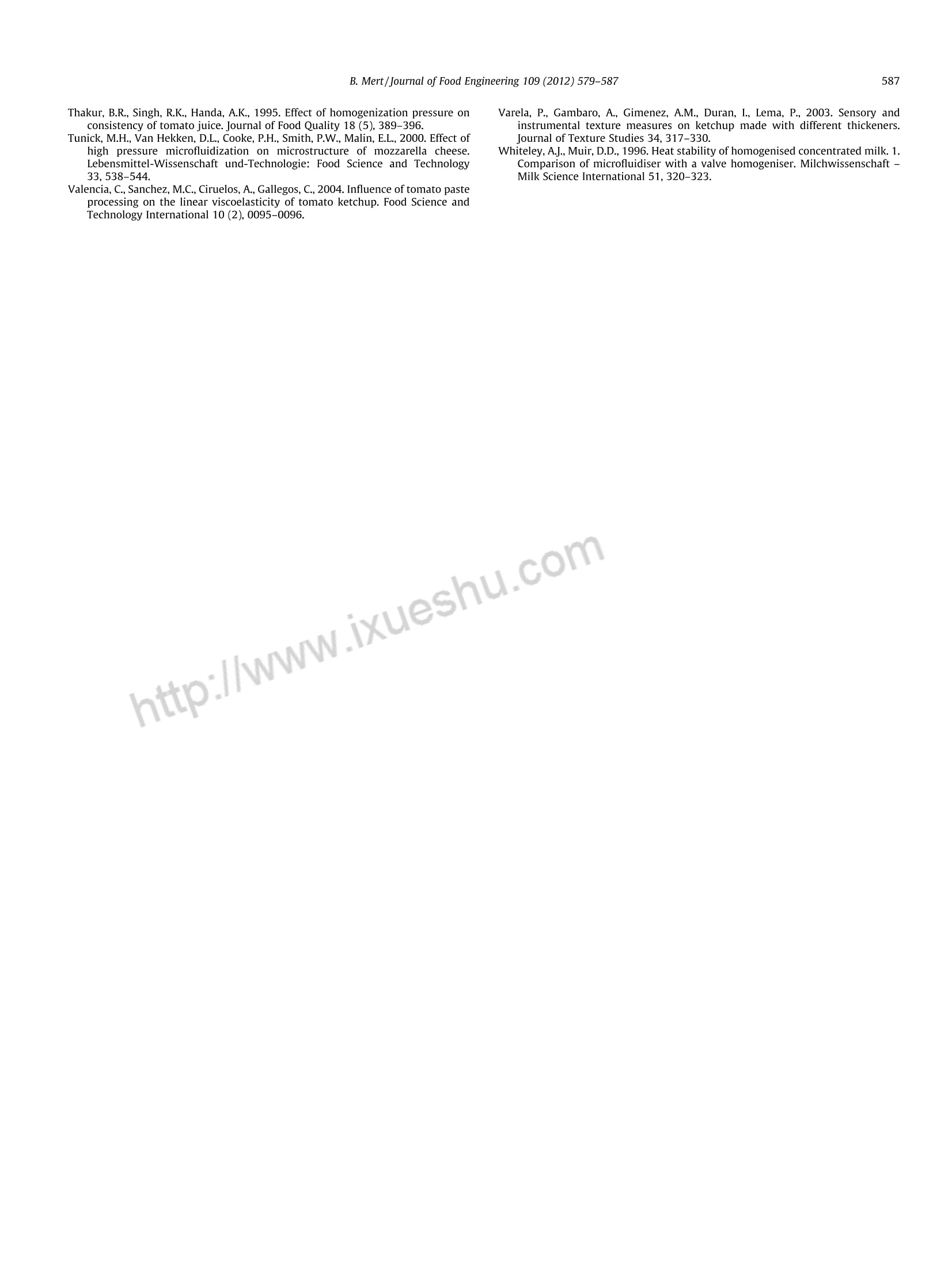

Journal of Food Engineering 109 (2012)579-587 580B. Mert/Journal of Food Engineering 109 (2012) 579-587 Contents lists available at SciVerse ScienceDirect journal of Food Engineering E LSEVIER journalhomepage: www.elsevier.com/locate/jfoodeng Using high pressure microfluidization to improve physical properties andlycopene content of ketchup type products Behic Mert* Food Engineering Department, Middle East Technical University, Ankara 06800, Turkey ARTIC L EIN F O ABSTRAC T Article history: This study evaluates the effects of high pressure microfluidization of ketchup mixes on the physical prop- Received 9 August 2011 erties and lycopene content. During the processing the pressure level ranged between 200 and 2000 bar, Received in revised form 16 October 2011 while the number of passes was kept constant. When the treatment pressure was increased from 200 to Accepted 20 October 2011 1200 bar, the yield stress, elastic modulus, storage modulus, and Bostwick consistency values of the Available online 29 October 2011ketchup samples improved. However, over-processing was observed for the samples treated at 1600 and 2000 bar. Light and scanning electron microscope images were used as visual means to observe Keywords: microfluidization induced structural changes. Colloidal stability measurement showed that increasing Microstructuremicrofluidization pressure improved physical stability of the samples. Reducing the size and changing Tomato Microfluidizationthe nature of tomato solids through high pressure microfluidization also increased the detectable lyco- Homogenization pene levels of the ketchup samples. Rheology@ 2011 Elsevier Ltd. All rights reserved. Fibers Ketchup otp://www.ixue Ketchup is one of most commonly consumed condiment madefrom either fresh tomatoes or from the concentrates such as tomatopurees and tomato pastes. The spice and seasonings are added to to-mato paste to give it thecharacteristic flavor. Depending on the localregulations gums and starches can be also used for their ability to actas water binding and bodyingagents.Although corn starch is usuallypreferred due to its low cost, it may cause some quality problemssuch as retrogradation (Varela et al., 2003). It is therefore pertinentthat numerous studies have focused on the incorporation of gumsinto ketchup products (Sidhu et al., 1997, Gujral et al., 2002; Varelaet al., 2003; Sahin and Ozdemir, 2004,2007; Koochekiet al.,2009). Ingeneral, it has been reported that a higher consistency and a lowerserum separation were observed when gums were used in ketchupproduction.However,it is important to note that usage of non-toma-to based thickeners in ketchup such as starches and gums is not per-mitted in certain countries. Furthermore, there is an increasingtrend for clean food labels and the consumers tend to prefer foodproducts with minimum additives. Color, flavor, and flow properties are the primary qualityparameters of ketchup.Rheological properties of ketchup stronglydepend on the amount of pectin, enzymatic degradation, pectin/protein fraction, pulp content, and homogenization process. The * Tel.: +90 312 2105634; fax: +90 312 2102767. ( E-mail address: bmert@ m etu.edu.tr ) ( 0260-8774/$ - see front matter C 201 1 Else v ier Ltd. All rights reserved. doi:10. 1 01 6 /j . jfoodeng.2011.10.02 1 ) consistency of ketchup is considered as a critical physical propertywhich is commonly monitored by most of the ketchup producersvia Bostwick Consistometers. Other rheological parameters suchas the linear viscoelastic properties and yield stress of ketchupare also regarded as important because they provide detailed infor-mation about the microstructure (Valencia et al., 2004). They arealso important for the handling, processing and storage (Sharobaet al., 2005). A number of studies have shown the relationship be-tween the rheological properties and quality parameters tomato-based products (Varela et al., 2003; Sahin and Ozdemir, 2004;Valencia et al., 2004; Anthon et al., 2008; Bayoda et al., 2008;Koo-cheki et al., 2009; Panovská et al., 2009). These studies often in-cluded some type of hydrocolloid1 to improve rheologicalproperties of ketchup.However, another way to enhance consis-tency of ketchup is processing with valve homogenization. Gener-ally, two stage, homogenization isutilizedin iiindustrialapplications to produce glossy and smooth ketchup products. Itimproves overall ketchup quality by breaking up the fibrous toma-to structure and reducing average particle size (Thakur et al., 1995;Bayod et al., 2007; Bayod and Tornberg, 2011). In conventionalhomogenization the ketchup is forced through a microscopic open-ing in the homogenizing valve. This creates high turbulence andshear, combined with compression, acceleration, pressure drop,cavitations, and impact. Consequently, disintegration and disper-sion of the tomato solids throughout the ketchup take place. Microfluidization as a novel mean of homogenization technol-ogy is gaining popularity. It consists of reaction chamber in which the fluid is forced to divide into two microstreams which then col-lide with each other at very high speeds (Cook and Lagace, 1987).Microstreams are not only exposed to high shear rate but also toextreme impact forces that cause the formation of fine particle(McCrae, 1994). This technique has gained popular use in pharma-ceutical and cosmetic industries. In food processing microfluidiza-tionhassbeenaapplied asanoveltechnique for milkhomogenization (Cobos et al., 1995; Dalgleish et al., 1996; Hard-ham et al., 2000; McCrae, 1994; Strawbridge et al.,1995; Whiteleyand Muir, 1996). Other products tested for the possibility of usingmicrofluidization include cheese (Lemay et al., 1994; Lebeuf et al.,1998; Tunick et al., 2000), yogurt (Ciron et al., 2010), cream li-queurs (Paquin and Giasson, 1989) and ice cream (Olson et al.,2003). Lagoueyte and Paquin (1998) analyzed the effects of micro-fluidization on functional properties of Xanthan gum and observeda reduction in thickening and stabilizing properties with an in-crease in pressure as well as the number of passes through thedevice. High intensity shearing and homogenization are often used infood processing. Number of studies showed that microfluidizationof emulsions and suspensions provides some unique structuralchanges which in turn affect the overall physical properties. Theintensity and duration of the shear rates are very high in microflu-idization compared to similar instruments. Although there manystudies about various applications of microfluidization, there arefew studies related to food treatment with microfluidization.Therefore,the objective of this study is to investigate the effectof high shear high microfluidization on microstructure, physicalproperties and available lycopene content of the ketchup product. 2. Materials and methods//www.ixuesl 2.1. Ketchup preparation Ketchup mixes were prepared in 1 kg batches prior to microflu-idization. 30°Brix tomato paste was obtained from a local pro-ducer. The ingredients typically used in ketchup preparationwere added into the mix in following quantities by weight, 35%water, 26.5% tomato paste (30 °Brix), 17.5% high fructose corn syr-up (42 DE), 8.5% corn syrup (84°Brix), 3% salt, 9% vinegar, 0.5%onion powder. Initially, the tomato paste was mixed (IKA RW 20,Germany) with water until all the lumps were disappeared. Thenother ingredients were slowly added and the mixture was heatedto 80°C with a constant agitation using a mixer (IKA RW 20).The heating step was conducted in an open stainless steel con-tainer placed in a water bath. After adding the evaporated waterback to the mixture (initial and final weights were measured),the homogenization (M-110Y Microfluidics, USA) step was per-formed. Finally, the microfluidized samples were sheared at1000 rpm for 3 min using a mixer (IKA RW 20, Germany) and filledinto 200 mLjars. Cooled samples were stored at ambient tempera-ture for one day before any further analysis. 2.2. Lycopene determination The ketchup samples (4±0.01 g) were weighed into a 200-mLflask and wrapped with aluminum foil to prevent exposure to light.One hundred milliliters mixture of hexane-acetone-ethanol solu-tion (2:1:1v/v) was added to the flask to solubilize carotenoids.The samples were agitated continuously for 10 min on a magneticstirrer plate after which 15 mL of distilled water was added withfurther agitation for 5 min before resting it. The solution separatedinto distinct polar and nonpolar layers, the hexane layer was sep-arated. The hexane layer containing lycopene was decanted and fil-tered through a 0.2-um filter paper. The filtrate was diluted with a hexane-acetone-ethanol solution (2:1:1 v|v). The colorless residueon the filter paper indicated rapid and complete the extraction oflycopene. Lycopene content of each sample was obtained by mea-suring the absorbance of lycopene hexane solution at 472 nm. Theextraction step was repeated twice and three measurements wereobtained from each extract and average values with standard devi-ations were reported. 2.3. Bostwick flow index Bostwick flow index of the products were determined using aBostwick Consistometer. At first the reservoir of the consistometerwas filled to top with 75 mL of the sample at 25C. Then the springloaded gate was opened and the distance that the sampled flowedin 30 s was recorded. This experiment was repeated 5 times foreach sample and the average values were reported. 2.4. Rheological measurements Dynamic rheological characterization of the ketchup sampleswas obtained using a controlled stress rheometer (TA 2000, Eng-land) at 25C. Parallel plate geometry with 40 mm plate diameterwas used. The stress sweep tests were performed at 1 Hz frequencyand minimum stress started from 1.5 Pa. The frequency sweeptests were carried out under linear conditions between 0.05 and66 rad/s. All the measurements were repeated three times andthe average values for each frequency were used to plot graphs.For the determination of the serum viscosity, the ketchup sampleswere centrifuged at 10,000 rpm for 15 min and the supernatant re-moved. Finally, steady shear experiments were performed usingcone and plate geometry. 2.5. Particle size measurement Average median particle sizes were determined using a laserscattering analyzer (Malvern Mastersizer 2000, England). Themean particle sizes of the surface-area-weighted (d32) and vol-ume-weighted (d43) distributions were calculated using the instru-ment's software. Samples of each treatment were run at least threetimes and average values were reported. 2.6. Scanning electron and light microscope observations Ketchup samples were centrifuged (10,000g) for 5 min, thesupernatant was discarded and the residual part was frozen byimmersion in liquid nitrogen. The frozen samples were furtherdried in a freeze drier using freeze drier. Finally, the samples wereanalyzed by a scanning electron microscope (QUANTA 400F FieldEmission SEM) following gold coating. Light microscope observations (Leica DM3000, Germany) werecarried out after diluting the samples with 50% (w/w) water under40x magnifications. Ten microlitres of each sample was placed ona slide and a cover glass was placed on the sample. The imageswere taken using a digital camera (Leica DFC290, Germany). 2.7. Color measurement The samples were filled into a clear glass Petri dish and colorparameters (a* and b*) were determined using a Minolta colorim-eter (CM-3600d, United Kingdom). The petri dish was placed onthe colorimeter sensor during measurements. Three measure-ments were taken for each sample and average values werereported. Stability of the samples was determined using Lumisizer disper-sion analyzer (L.U.M., Berlin, Germany). It is a temperature regu-lated multi-sample analytical centrifuge device where theintensity of the parallel transmitted NIR light over the entire sam-ple length is measured at certain time intervals. The measurementscheme is shown in Fig. 1. The time evolution of the transmissionprofiles contains the information on the kinetics of the concentra-tion changes due to phase separation. All measurements were con-ducted at 10°C and 2000 rpm for 30 min. 2.9. Statistical analysis One-way analysis of variance (ANOVA) was applied to deter-mine the differences between valve and microfluidizer homogeni-zation at 200 bar. It was used to test any significant differencesbetween microfluidized samples treated at different pressures(p≤0.05). 3. Results and discussion Light microscope images (Fig.2) of the valve homogenized andmicrofluidized ketchup samples are shown. The differences be-tween the microstructure of valve homogenized sample (Fig. 2a)and microfluidized sample (Fig.2b) clearly indicate the intense im-pact of the microfluidization. Although these two samples werehomogenized at similar pressure, more pronounced disintegrationof the cellular material was observed in the microfluidized sample.Furthermore, as the pressure of microfluidization was elevated, cellstructures were dissociated even more. The microstructures shownin Fig. 2c and d still had aggregates of the cellular fragments, butthe amount of visible aggregates significantly reduced in the sam-ples shown in Fig. 2e and f. Both homogenization and microfluidi-zation destroyed the cellular matrix, however the attained shearrates were much higher in the former than the latter. Hence,microfluidized samples tend to have more fibrils rather than individual tomato solid fibers. When the microfluidization pres-sure was increased to 1600bar (Fig. 2e) and 2000 bar (Fig. 2f),signs of over processing were observed with the disappearance ofthe dark areas. Increasing pressure may result in the formation ofshorter fibers and fibrils, which in turn may also prevent fibersto intertwine and form a network of aggregates. Vanishing of thedark areas (especially in Fig. 2e and f) may be explained with theformation of much shorter tomato solid fibers and fibrils at higherpressures. The decrease of the median particle (Table 1) size of theketchup samples correlates with the microscopic observations.Fig. 3 depicts the scanning electron microscope observations ofthe valve and microfluidizer homogenized ketchup samples. Toma-to fibers tend to interwine and form a lattice network that providescharacteristic rheological properties to ketchup products. In Fig. 3aand b, relatively large pulp particles rather than finely divided fi-brous structures were observed. As the microfluidization pressureelevated, fibers were fibrillated into smaller fragments appeared inFig.3c and d. When the pressure was further increased to 1600 barand 2000 bar, the images shown in Fig. 3e and f were obtained,respectively. It is pertinent that high pressure homogenizationusing microfluidizer increased the dissociation of the tomato solidsand caused formation of the porous structures shown in Fig. 3e andf. Tomato products are typical concentrated food suspensions,consisting of whole cell fragments suspended in an aqueous con-tinuous phase. The aqueous phase also contains soluble tomatosolids such as, sugars, soluble pectin and proteins. Hence, tomatobased products, including ketchup, display complex rheologicalbehaviors. They are generally shear thinning fluids that exhibit ayield stress. Because of the yield stress, a ketchup container is oftenrequired to be shaken or squeezed to dispense the ketchup.There-fore, the yield stress values of microfluidized samples were alsodetermined in this study as shown in Fig. 4. The stress values, mea-sured as the onset of the flow, were also reported as yield stressvalues in Table 1. Increasing yield stress with rising microfluidiza-tion pressure showed a stronger gel formation with network of fi-bers and fibrils. However, when the pressure exceeded 1600 bar, a Fig. 2. Light microscope picture of ketchup samples, (a) valve homogenized at 200 bar, (b) microfluidized at 200 bar,(c) microfluidized at 600 bar (d) microfluidized at1200 bar,(e) microfluidized at 1600 bar, and (f) microfluidized at 2000 bar. Table 1 Mean particle sizes, Bostwick flow index, lycopene content,yield stress, and color of the valve homogenized (HM) control sample and microfluidized (MF) samples. Particle size Particle size Bostwick Lycopene content Yield Complex Color d32(um) d43 (um) index (cm/30s) (mg/100 g wet wt.) stress (Pa) modulus (Pa) a*/b* HM 200 bar 151±5 328±11 5.5±0.3 14.9±1.2 9.4±0.9 524±21 1.7±0.1 MF 200 bar 123±5 211±9 4.8±0.2 17.1±0.4 15.1±1.3 691±36 1.9±0.2 MF 600 bar 81±3 184±3 4.2±0.3 20.1±1.4 17.3±2.1 816±59 2.0±0.1 MF 1200 bar 66±4 97±4 3.3±0.1 24.2±2.4 27.6±3.4 1259±92 2.0±0.0 MF 1600 bar 38±3 82±3 3.6±0.1 25.5±2.0 21.4±2.6 1167±96 2.2±0.2 MF 2000 bar 29±2 75±3 4.0±0.2 28.2±2.2 20.9±3.1 898±54 2.3±0.2 decrease in the yield stress values were recorded. Based on the par-ticles size results given in Table 1 and the microscopic images gi-ven in Figs. 2 and 3, it can be concluded that over processingstarted at 1600 bar. The length of the individual fibers was reducedso much that they started to lose the ability of intertwining andforming strong fibrous matrix. Elastic and viscous moduli values of the ketchup samples are gi-ven in Figs. 5 and6. In concentrated suspensions like ketchup, fi-bers and fibrils entangle with each other and provide the solid like properties (G’>G"). For all of the samples, the elastic modulusvalues were higher than the viscous modulus values, indicatingcharacteristic gel-like structure of the ketchup. When the conven-tional valve and microfluidizer homogenized samples were com-pared at 200 bar pressure, higher moduli values were recordedfor the microfluidized sample. The main advantage of microfluidiz-er over conventional valve homogenizer is its ability to producehigher shear rates for longer periods of time. Usually conventionalvalve homogenizer operates at cycle mode and its pressure fluctu- nttp Fig. 3. Scanning electron microscope picture of ketchup samples, (a) valve homogenized at 200 bar, (b) microfluidized at 200 bar, (c) microfluidized at 600 bar, (d)microfluidized at 1200 bar,(e) microfluidized at 1600 bar, and (f) microfluidized at 2000 bar. ates between a maximum and a minimum, allowing some of thetomato pulps pass through homogenizer opening without process-ing. On other hand microfluidizer provides consistent pressureduring its operation and provides more uniform particle distribu-tion. It is evident in Fig. 2a and b (also in particle size values in Ta-ble1) that microfluidized sample haddhigher degree ofdisintegration of the fibers with more uniform distribution(Fig.2b) compared to valve homogenized samples (Fig. 2a). There-fore these two samples had different rheological properties,although they were homogenized at same pressure. The trend ofincreasing viscous and elastic moduli values continued until thepressure reached 1200 bar. However, when the pressure was fur-ther increased, moduli values started to decrease proportionatelyto the yield stress values. For ease of comparison, complex modu-lus values of the samples at 10 Hz (~62.8 rad/s) are given in Ta-ble 1. This result also indicates the over processing of thesamples, extreme fibrillation and size reduction prevents forma-tion strong matrices for the samples processed above 1200 bar. Serum separation is a commonly encountered stability problemin ketchup products and especially noticeable when the ketchupdoes not contain any non-tomato hydrocolloid such as gums andstarch. In order to characterize the effect of the microfluidizationon colloidal stability the Lumizer (L.U.M., Berlin, Germany) wasemployed. After placing the samples in special tubes as shown inFig. 7, the tubes were centrifuged at 10℃ at 2000 rpm for30 min followed. The phase separation was monitored using aNIR light source and CCD sensor. Typical light transmission profilesare given in Fig. 8. As colloidal particles settle down the region thattransmits light expands, the rate and extent of the expansion canbe measured. The effect of microfluidization is seen in Fig. 7.Although the samples labeled with ‘a’and “b’were homogenizedat the same pressure, sample given in Fig. 7b had clearly better sta-bility than the one shown in Fig. 7a. This was probably caused bythe formation of greater number of fibers and fibrils in microfluidi-zation compared to valve homogenization. The samples from ‘b’to‘f, microfluidized at different pressures, showed the improved col- Shear Stress [Pa] Fig. 4. Yield stress measurements of the ketchup samples. Legends are (●) valvehomogenized at 200 bar, (口) microfluidized at 200 bar, (◆) microfluidized at600 bar, (◇) microfluidized at 1200 bar, (■) microfluidized at 1600 bar, and (O)microfluidized at 2000 bar. Fig. 5. Storage modulus values of the ketchup samples. Legends are (●) valvehomogenized at 200 bar, (口) microfluidized at 200 bar, (◆) microfluidized at600 bar,(◇) microfluidized at 1200 bar, (■) microfluidized at 1600 bar, and (O)microfluidized at 2000 bar. loidal stability with increasing treatment pressure. This can also beexplained with the formation smaller particles and fibers withincreasing pressure. Smaller particle size and higher continuousphase viscosity can effectively improve stability of the samplesby slowing down the particle sedimentation velocity. Fig. 9 shows the change of % transmission with respect to cen-trifugation time. One can notice that the slope of this graph is equalto velocity of sedimentation of the tomato solids. Microfluidizationresulted in slower velocity of sedimentation compared to valvehomogenization. On the other hand, increased pressure of micro-fluidization noticeably improved colloidal stability and sloweddown the velocity of sedimentation. Homogenization does not onlyeffectively reduce the diameter and size of the fiber, but also re-leases pectin and pigments such as lycopene. The increase in theserum viscosity shown in Fig. 10 indicates the release of the solu-ble materials, especially the entrapped pectin, into the continuous Fig. 6. Loss modulus values of the ketchup samples. Legends are (●) valvehomogenized at 200 bar, (口) microfluidized at 200 bar, (◆) microfluidized at600 bar, (◇) microfluidized at 1200 bar, (■) microfluidized at 1600 bar, and (O)microfluidized at 2000 bar. Fig. 7. Ketchup samples in Lumisizer tubes after measurement, (a) valve homog-enized at 200 bar, (b) microfluidized at 200 bar, (c) microfluidized at 600 bar, (d)microfluidized at 1200 bar,(e)microfluidized at 1600 bar, and (f) microfluidized at2000 bar. liquid phase. Increasing soluble material concentration in the ser-um phase actually changed flow behavior from Newtonian tonon-Newtonian when the microfluidization pressure exceeded600 bar. The ketchup rheology depends on both the size and natureof insoluble materials and viscosity of the continuous phase. There-fore, increased serum viscosity might explain the relatively highBostwick consistency of the samples microfluidized at 1600 and2000 bar, although they had relatively small average particle sizes. A number of studies (Sadler et al., 1990; Rao et al., 1998;Marko-vicet al., 2006) have demonstrated that rapid extraction of lyco-pene followed by spectrophotometric determination if it was themain carotenoid in a food material is an acceptable measurementtechnique. Changing the size and nature of the tomato solidsthrough microfluidization also caused some changes in the lyco-pene content of the samples. In fact, detectable lycopene contentalmost doubled with microfluidization at 2000 bar compared with http:/// the valve homogenization at 200 bar (Table 1). Furthermore, com-parison of the two homogenization methods at the same pressure(200 bar) showed that detectable lycopene content was higher inthe microfluidized sample (p<0.05). Increased level of the avail-able lycopene was further evident with the increase in valuesshown in Table 1. The a*/b* ratio is often used as a quality param-eter in tomato based products (Lehkozivova et al., 2009). A positivevalue of a* indicates redness, and a negative value greenness. Sim-ilarly, a plus value for b* indicates yellowness and a minus valueblueness. In case of ketchup both a* and b* values are expectedto be positive. Furthermore, a* b* values over 1.8 are consideredacceptable and below this level is regarded as undesirable (Gooseand Binsted, 1973; Barreiro et al., 1997). As shown in Table 1 a*/b* ratio clearly increased with increasing microfluidization pres-sure. Since the lycopene is responsible for tomato redness, increas- ing a*b* ratio agrees with results given for available lycopenevalues in Table 1. 4. Conclusion It has been long recognized that homogenization of the tomatoproducts significantly alters the network formed by the intertwin-ing tomato fibers. In this study two homogenization techniques,valve and microfluidization, were compared at 200 bar in termsof quality parameters of the final product. Microfluidization wasmore effective in disintegrating tomato solids. Moreover, higherpressures which cannot be reached with conventional valvehomogenization were also tested by using microfluidization. In-creased microfluidization pressures led to some improvements in Fig.9. Change of total transmission with time under centrifugal force. Legends are(●) valve homogenized at 200 bar, (口) microfluidized at 200 bar,(◆) microfluidizedat 600 bar, (O) microfluidized at 1200 bar, (■) microfluidized at 1600 bar, and (◇)microfluidized at 2000 bar. Fig. 10. Serum viscosity of the ketchup samples. Legends are (●) valve homoge-nized at 200 bar, (口) microfluidized at 200 bar, (◆) microfluidized at 600 bar,(O)microfluidized at 1200 bar, (◇) microfluidized at 1600 bar, and (■) microfluidizedat 2000 bar. physical quality parameters and lycopene content of the ketchupsamples. However, very high pressures (such as 1600 bar andabove) resulted in extremely small fibers and fibrils, decreasingmoduli, yield stress and Bostwick consistency. On the other hand,higher the microfluidization pressure resulted in higher serum vis-cosity and detectable lycopene content for the range of the pres-sures tested. Therefore. using microfluidization forhomogenization of the tomato based condiments can be recom-mended as a novel process. Acknowledgement The author acknowledges the financial support of The Scientificand TechnologicalResearch Council of Turkey (Project No.108M169). Anthon, G.A., Diaz, J.V., Barrett, D.M., 2008. Changes in pectins and productconsistency during the concentration of tomato juice to paste. Journal ofAgricultural of Food Chemistry 56,7100-7105. Barreiro, J.A., Milano, M., Sandoval, A.J., 1997. Kinetics of colour change of doubleconcentrated tomato paste during thermal treatment. Journal of FoodEngineering 33, 359-371. Bayod, E., Tornberg, E., 2011. Microstructure of highly concentrated tomatosuspensions on homogenization and subsequent shearing. Food ResearchInternational 44 (3),755-765. Bayod, E., Mansson, P., Innings, F., Bergenstahl, B., Tornberg, E., 2007. Low shearrheology of concentrated tomato products. Effect of particle size and time. FoodBiophysics 2 (4), 146-157. Baiyyoda, E., Willers, E.P., Tornberg, E., 2008. Rheological and structuralcharacterization of tomato paste and its influence on the quality of ketchup.LTW 41, 1289-1300. Ciron, C.I.E., Gee, V.L., Kelly, A.L., Auty, M.A.E., 2010. Comparison of the effects ofhigh-pressure microfluidization and conventional homogenization of milk onparticle size, water retention and texture of non-fat and low-fat yoghurts.International Dairy Journal 20 (5),314-320. Cobos, A., Horne, D.S., Muir, D.D.,995. Rheological properties of acid milk gels. 1.Effect of composition, process and acidification conditions on products fromrecombined milks. Milchwissenschaft -Milk Science International 50,444-448. Cook, E.J., Lagace, A.P., 1987. Forming a microemulsion- comprises impingingstreams of mixtures containing components of micro-emulsion into each otherat high pressure in low pressure zone. US Patent US4908154-A. Dalgleish,D.G., Tosh, S.M., West, S., 1996. Beyond homogenization: the formation ofvery small emulsion droplets during the processing of milk by a microfluidizer.Netherlands Milk and Dairy Journal 50, 135-148. Goose, P.G., Binsted, R., 1973. Tomato Paste and Other Tomato Products, second ed.Food Trade Press Ltd.,England. Gujral, H.S., Sharma, A., Singh,N., 2002. Effect of hydrocolloids, storage temperature,and duration on the consistency of tomato ketchup. International Journal ofFood Properties 5, 179-191. Hardham, J.F., Imison, B.W., French, H.M., 2000. Effect of homogenisation andmicrofluidisation on the extent of fat separation during storage of UHT milk.Australian Journal of Dairy Technology 55, 16-22. Koocheki, A., Ghandi, A., Razavi, M.A.S., Mortazavi, S.A., Vasiljevic, T., 2009. Therheological properties of ketchup as a function of different hydrocolloids andtemperature. International Journal of Food Science and Technology 44, 596-602. Lagoueyte, N., Paquin, P., 1998. Effects of microfluidization on the functionalproperties of xanthan gum. Food Hydrocolloids 12 (3), 365-371. Lebeuf, Y., Lacroix, C., Paquin, P., 1998. Effect of incorporation of denatured and microparticulated whey protein in young cheddar cheese. Lait 78, 303-318.Lehkozivova, J., Karovicova, J., Kohajdova, Z., 2009. The quality and authenticity markers of tomato ketchup. Acta Chimica Slovaca 2 (2), 88-96. Lemay, A., Paquin, P., Lacroix, C., 1994. Influence of microfluidization of milk oncheddar cheese composition, color, texture, and yield. Journal of Dairy Science77,2870-2879. Markovic, K., Hruskar, M., Vahcic, N., 2006. Lycopene content of tomato productsand their contribution to the lycopene intake of Croatians. Nutrition Research26,556-560. McCrae, C.H., 1994. Homogenization of milk emulsions - use of microfluidizer.journal of the Society of Dairy Technology 47, 28-31. Olson, D.W., White, C.H., Watson, C.E., 2003. Properties of frozen dairy dessertsprocessed by microfluidization of their mixes. Journal of Dairy Science 86,1157-1162. Panovska, Z., Sern, P., Vachova, A., Lukesova, D., Pokorny, J., 2009. Textural andflavour characteristics of commercial tomato ketchups. Czech Journal of FoodSciences 27 (3),165-170. Paquin, P., Giasson, J., 1989. Microfluidization as an homogenization process forcream liqueur. Lait 69, 491-498. Rao, A.W., Waseem, Z., Agarwal,S., 1998. Lycopene content of tomatoes and tomatoproducts and their contributionto0dietary lycopene. Food ResearchInternational 31 (10), 737-741. Sadler, G., Davis,J., Dezman, D.,1990. Rapid extraction of lycopene and b-carotenefrom reconstituted tomato paste and pink grapefruit homogenates. Journal ofFood Science 55 (5), 1460-1461. Sahin, H., Ozdemir, F., 2004. Effect of some hydrocolloids on the rheologicalproperties of different formulated ketchups. Food Hydrocolloids 18,1015-1022.Sahin,H.,Ozdemir, F., 2007. Effect of some hydrocolloids on the serum separation of different formulated ketchups. Journal of Food Engineering 81, 437-446. Sharoba, A.M., Senge, B., El-Mansy, H.AMar., Bahlol, H.ElM., Blochwitz, R., 2005.Chemical, sensory and rheological properties of some commercial Germanand Egyptian tomato ketchups.European Food Research and Technology 220,142-151. Sidhu, J.S., Bawa, A.S., Singh, N., 1997. Studies on the effect of hydrocolloids on theconsistency of tomato ketchup. Journal of Food Science and Technology 34,423-424. Strawbridge, K.B., Ray, E., Hallett, F.R., Tosh, S.M., Dalgleish, D.G., 1995.Measurement of particle-size distributions in milk homogenized by amicrofluidizer - estimation of populations of particles with radii less-than100 nm. Journal of Colloid and Interface Science 171,392-398. Thakur, B.R., Singh, R.K., Handa, A.K., 1995. Effect of homogenization pressure onconsistency of tomato juice. Journal of Food Quality 18(5),389-396. Tunick, M.H., Van Hekken, D.L., Cooke, P.H., Smith, P.W., Malin, E.L., 2000. Effect ofhigh pressure microfluidization on microstructure of mozzarella cheese.Lebensmittel-Wissenschaft und-Technologie: Food Science and Technology33,538-544. ( Valencia,C . , Sanchez,M. C ., Ciruelos, A., Gallegos,C., 2004. Influence of tomato paste processing on t h e l i near viscoelasticity o f t omato k e tchup. Fo o d Science and T echnology International 10 (2),0095-0096. ) Varela, P., Gambaro, A., Gimenez, A.M., Duran, I, Lema, P., 2003. Sensory andinstrumental texture measures on ketchup made with different thickeners.Journal of Texture Studies 34, 317-330. Whiteley, A.J., Muir, D.D., 1996. Heat stability of homogenised concentrated milk. 1.Comparison of microfluidiser with a valve homogeniser. Milchwissenschaft -Milk Science International 51,320-323. 知网查重限时7折最高可优惠120元 本科定稿,硕博定稿,查重结果与学校一致 免费论文查重:http://www.paperyy.com 3亿免费文献下载:]http://www.ixueshu.com 超值论文自动降重:: http://www.paperyy.com/reduce_repetition PPT免费模版下载: http://ppt.ixueshu.com 番茄酱料的稳定性分析研究 1. 介绍番茄酱是最常食用的调味品之一,由新鲜番茄或浓缩番茄泥和番茄酱制成。在番茄酱中加入香料和调味料,使其具有独特的风味。按照相关食品安全规定,食用胶体和淀粉也可以用作保水剂和增稠剂。虽然玉米淀粉因其成本低而通常是首选,但它可能会导致一些质量问题,如回生。因此,越来越多的研究都聚焦在将食用胶体加入番茄酱产品中,在番茄酱生产中使用食用胶体,可以得到较高的稠度和稳定性。然而,值得注意的是,某些国家不允许在番茄酱中使用非番茄基增稠剂,如淀粉和食用胶体。此外,消费者倾向于选择加入更少添加剂的食品。然而,另一种提高番茄酱稠度的方法是用均质技术对产品进一步加工。一般来说,在工业中采用两段均质化方法生产质地细腻的番茄酱产品。它通过分解番茄纤维来提高番茄酱的整体质量,降低平均粒径。微射流作为一种新型的均匀化技术正在得到广泛的应用,该技术作为一种新型的牛奶均质技术,在食品加工中得到了应用。大量研究表明,微射流处理的乳液和悬浮液具有一些独特的结构变化,进而影响整体产品特性。Behic Merit 利用LUMiSizer对微射流处理的番茄酱产品稳定性进行了相关测试研究。 2. 实验将统一制作的番茄酱产品分为六份,分别在200 bar压力下均质处理(a)、200 bar压力下微射流处理(b)、600 bar压力下微射流处理(c)、1200 bar压力下微射流处理(d)、1600 bar压力下微射流处理(e)和2000 bar压力下微射流处理(f)。所有测量均在10℃和2000 rpm下进行30分钟。测试条件:NIR近红外光源、2000 rpm,在10℃条件下测试30min。3. 结果与分析体系分层是番茄酱产品中经常遇到的稳定性问题,特别是当番茄酱不额外添加的胶体(如食用胶体和淀粉)时。为了表征微射流对胶体稳定性的影响,使用LUMiSizer进行相关测试,测试后样品形态如图1所示,指纹图谱如图2所示。当颗粒沉淀下来,透射光的区域变大,变大的速度和程度就可以测量得到准确数据。尽管标记有“a”和“b”的样品在相同压力下均质化,图1中b样品明显比a样品具有更好的稳定性。可能是由于微射流处理形成的纤维和纤维束数量比均质化的多。在不同压力下微射流处理的样品从b到f的胶体稳定性随着处理压力的增加而提高。换言之,更小的粒子和纤维随着压力的增加而形成。较小的颗粒尺寸和较高的连续相粘度可以减缓颗粒沉降速度,有效地提高样品的稳定性。 图1 LUMiSizer 测试后番茄酱样品的形态(a)200 bar压力下均质处理、(b)200 bar压力下微射流处理、(c)600 bar压力下微射流处理、(d)1200 bar压力下微射流处理、(e )1600 bar压力下微射流处理和(f)2000 bar压力下微射流处理图2测量后番茄酱样品在LUMiSizer试管中的谱图及状态对照(A)200 bar压力下均质处理、(B)600 bar压力下微射流处理以及(C)2000 bar压力下微射流处理。 图3为样品透光率在测试过程中随时间的变化。图中的斜率表示番茄固形物的沉降速度。微射流处理过的样品沉积速度慢于均匀化。另一方面,随着微射流压力的增加,胶体的稳定性显著提高,沉降速度减缓。4 总结LUMiSizer®分散体系分析仪,应用STEP®技术,为酱料类产品的稳定性分析提供了快捷有效的工具。不仅一次可以测试12个样本,而且可多波长(近红外865nm+蓝光410nm)灵活的应用于样品性能测试,为用户可提供更多更深入的分析信息,大大提高了用户的工作效率。

确定

还剩8页未读,是否继续阅读?

罗姆(江苏)仪器有限公司为您提供《番茄酱中稳定性检测方案(激光光散射仪)》,该方案主要用于酿造酱中理化分析检测,参考标准--,《番茄酱中稳定性检测方案(激光光散射仪)》用到的仪器有罗姆分散体分析仪LUMiSizer ® 650

相关方案

更多

该厂商其他方案

更多