方案详情

文

电子纺织品在个人保健、运动监测、可穿戴通信和人机交互等领域具有潜在的应用,电源单元是其中关键的组成部分之一。为了满足下一代电子纺织品的要求,理想的电源应该具有高柔性与一维结构,能够通过传统的纺织技术如缝纫、编织和织造轻松地嵌入日常服饰中。生物体液是一种天然电解质,可以作为生物相容的能量来源,生物流体基能量装置分为两类:生物燃料电池(BFC)和汗液活化电池(SAB)。与BFC将生物体液中的化学能转化为电能不同,SAB使用汗液作为电解质,通过电极之间的氧化还原反应产生稳定的电输出。近年来,通过将纤维状超级电容器与SAB和BFC的混合系统相结合,可以建立高效的能量存储和高功率输出的混合能量供应系统。将超级电容器与基于棉纱的SAB集成起来,可以产生足够的能量以满足汗液激活的电子纺织品系统中各种便携式和可穿戴电子设备的需求。

方案详情

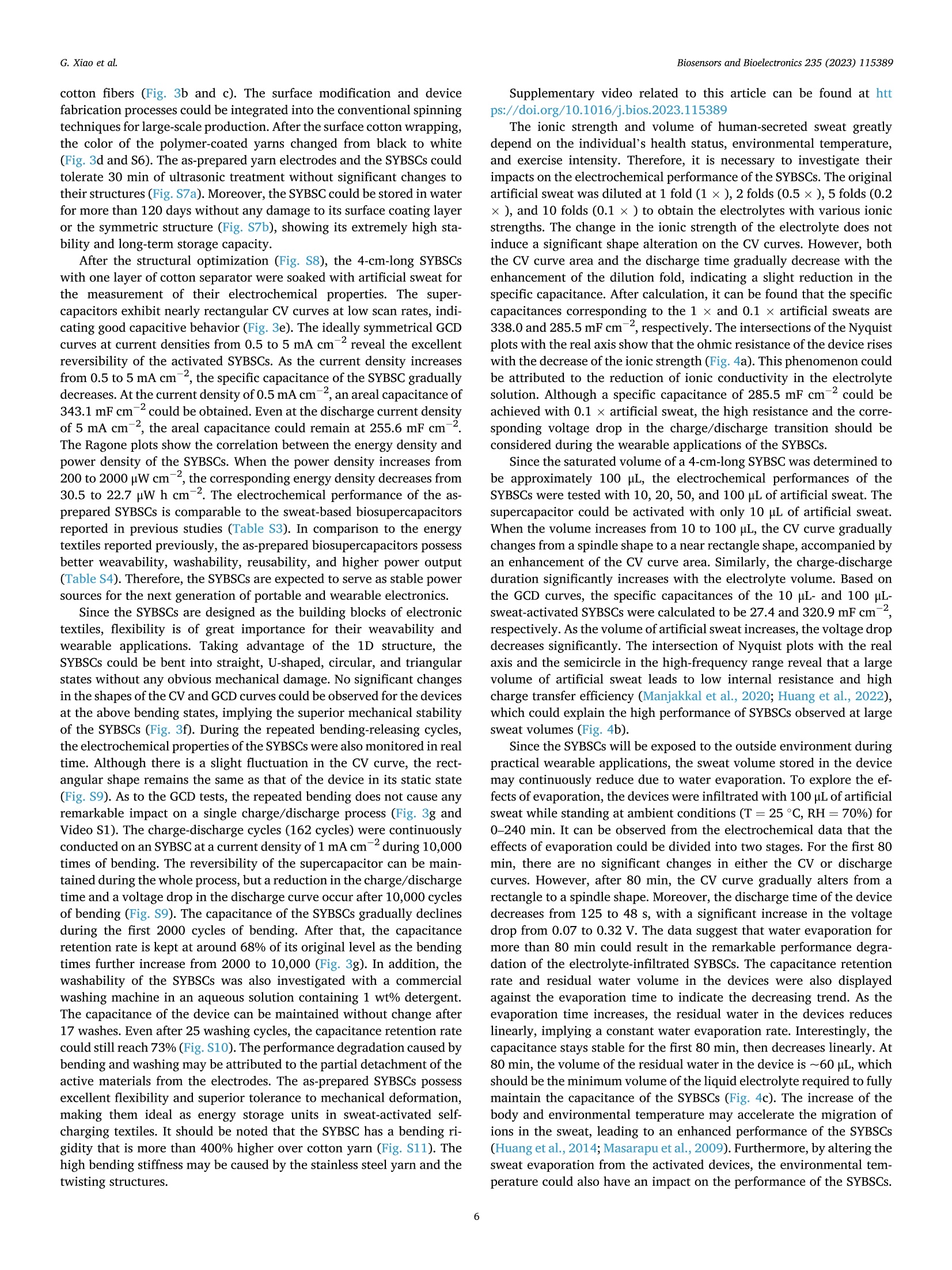

电子纺织品在个人保健、运动监测、可穿戴通信和人机交互等领域具有潜在的应用,电源单元是其中关键的组成部分之一。为了满足下一代电子纺织品的要求,理想的电源应该具有高柔性与一维结构,能够通过传统的纺织技术如缝纫、编织和织造轻松地嵌入日常服饰中。生物体液是一种天然电解质,可以作为生物相容的能量来源,生物流体基能量装置分为两类:生物燃料电池(BFC)和汗液活化电池(SAB)。与BFC将生物体液中的化学能转化为电能不同,SAB使用汗液作为电解质,通过电极之间的氧化还原反应产生稳定的电输出。近年来,通过将纤维状超级电容器与SAB和BFC的混合系统相结合,可以建立高效的能量存储和高功率输出的混合能量供应系统。将超级电容器与基于棉纱的SAB集成起来,可以产生足够的能量以满足汗液激活的电子纺织品系统中各种便携式和可穿戴电子设备的需求。图1. 纱线基汗液激发超级电容器的构建,及其集成到自充电、自供能、生物传感的电子织物中。近期,西南大学鲁志松教授、乔琰副教授课题组开发了一种柔性、可编织和大规模制备的纱线基汗液激发超级电容器(CYSAB),具有对称型的双电极结构,其中不锈钢纱线、导电聚合物和汗液分别作为集流体、活性材料和电解质。通过将聚合物PPy和PEDOT:PSS逐层沉积在不锈钢纤维制成的纱线上,以提高电容量。棉纤维包覆在聚合物功能化的不锈钢纱线上作为分离层,用于吸湿和贮存汗液。由于其极佳的柔韧性、可清洗性和可编织性,SYBSC可以与基于棉纱线的自供电电池(SABs)集成,构建混合自供电能源系统。混合自供电系统、无线数据采集芯片和碳纳米管纤维基汗液pH传感器集成,形成汗液激发自供电传感纺织品以分析锻炼过程中分泌的汗液,充分展示了该系统在实际应用中的潜力。相关工作以“Weavable yarn-shaped supercapacitor in sweat-activated self-charging power textile for wireless sweat biosensing”为题,发表在《Biosensors and Bioelectronics》上(原文链接:https://doi.org/10.1016/j.bios.2023.115389)。西南大学材料与能源学院鲁志松教授与乔琰副教授为共同通讯作者,2019级博士生肖刚和2020级硕士生巨俊为本文的共同第一作者。图2. 柔性、可编织和大规模制备的纱线基汗液激发超级电容器(CYSAB)构建。图3. 基于编织工艺构建自充电汗液激发超级电容器SYBSC和汗液激发电池CYSAB的集成织物。图4. 使用自充电织物的对人体汗液pH进行实时分析。 原文链接:https://doi.org/10.1016/j.bios.2023.115389本文中进行电化学测试的仪器为荷兰PalmSens,型号:PalmSens4便携式电化学分析仪,由雷迪美特中国有限公司提供。Biosensors and Bioelectronics 235 (2023) 115389Biosensors and Bioelectronicsjournal homepage: www.elsevier.com/locate/bios G. Xiao et al.Biosensors and Bioelectronics 235 (2023) 115389 Contents lists available at S c i enc e Direct Weavable yarn-shaped supercapacitor in sweat-activated self-charging power textile for wireless sweat biosensing Gang Xiao a b ,c ,1, Jun Ju a ,b ,c 1, Min Li a ,b ,c , Huajun Wu a b ,c , Yihao Jian a b,c , Wei Sun ,Wei Wang , Chang Ming Li , Yan Qiao a ,b ,c ,**, Zhisong Lu a ,b,c ,* a Institut e for Clean Energy & Advanced Materials, School of Materials & Energy, Southwest University, Chongqing, 400715, PR China DSino-Singapore Joint Laboratory of Materials and Technologies for Proactive Health Monitoring, School of Materials & Energy, Southwest University, Chongqing,400715, PR China Experimental Cente r for Virtual Simulation of Sports and Health, Southwest University, Chongqing, 400715, PR China “Key Laboratory of Laser Technology and Optoelectronic Functional Materials of Hainan Province, College of Chemistry and Chemical Engineering, Hainan Normal University, Haikou, 571158, PR China eSingapore Institut e of Manufacturing Technology, 138669, Singapore School of Mater i als Science and Engineering, Suzhou University of Science and Technology, Suzhou, 215011, PR China ARTICLEINFO ABSTRACT Keywords:Sweat-activated biosupercapacitor Yarn-shaped device Weavabi l ity Self-charging text i le Sensors The yarn-based sweat-activated battery (SAB) is a promising energy source for textile electronics due to its excellent skin compatibility, great weavabil i ty, and stable electric output. However, its power density is too low to support real -time monitoring and wireless data transmission. Here, we developed a scalable, high-performance sweat -based yarn biosupercapacitor (SYBSC) with two symmetrically aligned electrodes made by wrapping hydrophilic cotton fibers on polypyrrole/poly (3,4-ethylenedioxythiophene):poly (styrenesulfonate)-modified stainless steel yarns. Once activated with art i ficial sweat, the SYBSC could offer a high areal capacitance of 343.1mF cma t 0.5 mA cm. After 10,000 times of bending under continuous charge-discharge cycles and 25 cycles of machine washing, the device could retain the capacitance at rates of 68% and 73%, respectively. The SYBSCs were integrated with yarn-shaped SABs to produce hybrid sel f -charging power units. The hybrid units, pH sensing fibers, and a mini-analyzer were woven into a sweat-activated all-in-one sensing textile, in which the hybrid, self -charging units could power the analyzer for real-time data collection and wireless transmission. The al l -i n-one electronic textile could be successfully employed to real-time monitor the pH values of the volunteers’sweat during exercise. This work can promote the development of self-charging electronic textiles for monitoring human healthcare and exercise intensity. 1. Introduction Electronic textiles (e-text i les) have made great strides over the past decade for potential applications in personal healthcare (C h en et a l.2021a ,2022b ), sports monitoring (Xu e e t a l ., 2021; M e ng e t a l., 2022),wearable communication (Yan g e t a l ., 2021), and human-machine interaction (Chen e t a l., 2021b ; Ma et a l., 2022; Z h a o et a l ., 2021).The power supply unit has been regarded as one of the key components in e-textiles due to its critical role in maintaining the operation of electronic systems (Ch en e t a l ., 2022a; Liu et a l., 2018). To address the requirements of next-generation e-text i les, an ideal power source should be highly flexible and one-dimensionally structured, enabling easy integration in fabrics with conventional text i le techniques such as sewing, knitting, and weaving for daily wearable applications (Ma et a l .,2021; Do n g e t a l ., 2020; Li ao et a l ., 2022; Li n e t a l., 2022; Hua n g et al .,2020; Lib a no r i e t a l ., 2022). Various fiber-shaped energy storage devices have been developed and integrated into fabrics as flexible power sources to support mini-electronic components. As one of the vital constituents, organic, acidic, and alkaline polymeric electrolytes have been incorporated into the devices to achieve high performance * Corresponding author. Institute for Clean Energy & Advanced Materials, School of Materials & Energy, Southwest University, Chongqing 400715, PR China. ** Corresponding author. Sino-Singapore Joint Laboratory of Materials and Technologies for Proactive Health Monitoring, School of Materials & Energy, Southwest University, Chongqing, 400715, PR China. E-mail addresses: y an qi a o @swu .ed u.c n (Y.Qiao), zs l u@swu .ed u.cn (Z. Lu). Gang Xiao and Jun Ju contributed equally to this work. ht tps://d oi .or g/10.1016/j .bio s .2023.115389 Received 17 February 2023; Received in revised form 29 Apri l 2023; Accepted 12 May 2023 Available online 12 May 2023 (Bando d k a r et al ., 2020; Wu et al., 2020). However, they are normally corrosive and toxic, greatly hindering the involvement of those devices in skin-contact applicat i ons, in particular e-text i le-based wearable systems. Recently, biofluids excreted from the human body (such as sweat or urine) have been utilized as natural electrolytes to prepare biocompat-ible energy sources due to their high ion contents (M a n j ak ka l e t a l.,2021; Wei e t a l ., 2021; Zha ng e t a l., 2021). Biofluid-based energy de-vices can be mainly divided into two categories: biofuel cells (BFCs) (C a i e t al ., 2022; Kwon et a l., 2018; S u n e t al .,2021) and sweat-activated batteries (SABs) (Li u et a l ., 2022a , 2022b; L v et al ., 2021a ;O r t e g a et al ., 2019). Both of them have been successfully manufactured in a yarn shape to construct biocompatible, wearable, self-powered e-textiles with traditional sewing and weaving techniques (G ao et a l ., 2020; J u et a l ., 2023; Xi a o e t a l., 2022). Unlike BFCs, which convert chemical energy contained in biofluids, SABs use sweat as the electrolyte to initiate a redox reaction between the electrodes, result i ng in a stable electric output . In our previous work, a cotton-yarn-based SAB consist-ing of t thecarbon-black-modified 1cathodee,,salt bridge,and Zn-foi l-wrapped anode was fabricated as a scalable and weavable energy source for smart textiles (Xia o et a l ., 2022). Although the yarn-based SAB has demonstrated its capability to power low-power consumption devices, i ts practical applications are still greatly limited by its low power density (33.1 pW cm-), which cannot meet the energy re-quirements of mult i functional skin electronics, particularly wireless data analyzers, even when connected in a series-parallel configuration.Thus, it is highly des i rable to develop a yarn-based sweat-activated energy supply system with a high-power output for future i ntegration in sweat-triggered all-in-one e-text i les. Supercapacitors are a type of attractive energy storage device for high power output applications owing to thei r outstanding advantages of high power density, fast charging/discharging rates, and long cycle lives (Ma n ja k k al et a l ., 2020; L i et al ., 2018; Yu e t al., 2022; He et al.,2022; L ima e t a l ., 2020; To ng et a l ., 2022; Va g h a s iya e t al., 2022).Flexible, lightweight supercapacitors have been produced to build a hybrid energy supply system with SABs/BFCs for efficient energy stor-age and high-power outputs (L u o e t a l., 2019, 2021; L v e t a l ., 2018,2021b ; Y i n e t a l ., 2021a , 2021b ; Ga o e t a l ., 2022). In comparison to the SABs/BFCs, the output performances of the hybrid systems could be significantly improved, enabling the powering of the watchband (Luo e t a l., 2021), microcontroller unit (Y in et al., 2021b), display device (Yin e t a l ., 2021a ), and sensor-display system (Ga o e t a l ., 2022). Therefore,the integration of yarn-based SABs with supercapacitors could be a very promising solution to generating sufficient power for various portable and wearable electronics in sweat-activated e-textile systems. In t he previously reported sweat-based hybrid energy systems, t he supercapacitors were built on flexible 2-dimensional (2D) substrates,including papers (L uo et a l ., 2021), textiles (L v e t a l., 2018; S el va m an d Y im, 2023), or polymeric f i lms (L v et al ., 2021b ; S e l vam et a l ., 2022),with polyvinyl alcohol (PVA)-based hydrogels as quasi-solid electrolytes (see T able S1 in the ESI). The poor mechanical properties of PVA hydrogels may impede the merits of hybrid energy systems since wearable applications usually require repeated bending and twisting.The addition of alkalies or acids to the PVA hydrogels may also pose safety risks to the wearers. Moreover, the 2D architecture is incompat-ible with the weaving techniques, l i mi ti ng its integration with 1D yarn-shaped SABs to produce sweat-based self-charging e-texti l es. As an ideal high-output energy storage device matched with yarn-based SABs and e-textiles, the supercapacitor should meet the following re-quirements: (1) possessing a highly flexible, one-dimensional (1-D)structure, which could be easily adapted to the conventional textile techniques together with the yarn-based SABs; (2) consisting of skin-conforming and biocompatible materials, which could directly contact human skin for wearable electronics . In t his study, we developed a scalable, flexible, and weavable sweat-based yarn biosupercapacitor (SYBSC) with a symmetrically two- electrode structure , in which stainless steel f iber-based yarns, conduc-tive polymers, and sweat were employed as the current collectors, active materials, and electrolyte, respectively. Polypyrrole (PPy) and poly (3,4-ethylenedioxythiophene)/poly (styrenesulfonate) (PEDOT: PSS) were deposited layer-by-layer on a stainless-steel yarn to i ncrease the loading amount for high capacitance. Cotton fibers were wrapped on the polymer-functionalized stainless-steel yarn as the separating layer for sweat wicking and storage. Due to their great flexibility, washability,and weavabi l ity, the SYBSCs could be i ntegrated with the cotton-yarn-based SABs to construct a hybrid sel f -charging energy system. The SABs and SYBSCs in the system could be activated by human sweat to realize automatic self-charging in real time, achieving a significantly enhanced power output. Since sweat has been used as a non-invasive sample for health monitoring, the sweat-ac t ivated self-charging energy system is quite sui t able to power a wireless analyzer for the construction of an all -in-one sweat-sensing textile. To fully demonstrate the potential in practical applications, a hybrid self-charging system, a wireless data acquisition chip, and carbon nanotube fiber-based sweat pH sensors were integrated to form a sweat-activated self-charging sensing textile for the analysis of sweat secreted during exercise (Fig . 1). 2. Experimental section 2.1. Materials Pyrrole and dimethyl sulfoxide (DMSO) were purchased from Shanghai Adamas Reagent Co., Ltd . Ferric chloride (FeCl3·6H2O), ani-line, hydrochloric acid (HCl), sulfuric acid (H2SO4), lactic acid, urea,ammonium chloride (NH4Cl ), and acetic acid (CH3COOH) were bought from Shanghai Aladdin Biochemical Technology Co. Polyvinyl butyral (PVB) and the poly (3,4-ethylenedioxythiophene):polystyrenesulfonate (PEDOT:PSS, 1.3 wt%) solution were the products of Sigma-Aldrich (Shanghai, China). P-Toluenesulfonic acid (PTS) and the silver ink (density: 2.1-2.4 kg L -, viscosity: 16,000 mPa s) were purchased from Guangdong Kangde New Energy Technology, China and Chongqing Yousheng Print i ng Equipment Co., respectively. Three-ply stainless-steel yarns and carbon nanotube (CNT) fibers were obtained from Guangdong Aoshun New Material Co. and Chinese Academy of Sciences Chengdu Organic Chemical Co., respectively. Cotton yarns (diameter: ~0.35mm)were commercially purchased from a local market in Chongqing, China. 2.2. Electrode preparation PPy and PEDOT :PSS were repeatedly deposited on the stainless steel yarns to form a mult i layered f ilm. Each round of bilayer i mmobilization includes a vapor deposition of PPy and a dip-coating of PEDOT:PSS.Before surface modification, the stainless-steel yarns were ultrasonical l y cleaned with water and dried in ambient conditions for further use . In a PPy vapor deposition procedure, the yarns were slowly immersed in an oxidant solution containing 0.1092 g mL - of FeCl3 and 0.0772 g mL -of PTS. Subsequently, the oxidant solution-infiltrated yarn I s S were Fig. 1. Construction of a yarn-shaped sweat-activated supercapacitor and its integration ir a sweat-activated all-in-one e-textile for wireless sweat monitoring. exposed to a vacuum cylinder fi l led with pyrrole vapor for 1 h. After being washed with water, the PPy-coated yarns were dried at 60°C for 1h. As to the PEDOT:PSS immobilization, the yarns were soaked in a 1.3wt% PEDOT:PSS ink containing 5 wt% DMSO to absorb suf f icient conductive polymers, followed by a 60°C drying for 4 h. The above procedures were repeated several times to enable the layer-by-layer immobi l ization of PPy and PEDOT:PSS. The mass change of the elec-trode after the polymer deposi t ion was obtained with an electronic balance. The mass difference was divided by the yarn’s surface area to determine the polymer density. All supercapacitor tests were performed with a homemade artificial sweat containing 20 g L- NaCl, 17.5 g L-1NH4Cl, 5.0 g L -l urea, 5.0 g L - CHgCOOH, and 15.0 g L -l lactate. The pH of arti f icial sweat was adjusted to 6.0 using 0.1 mM NaOH. 2.3. Assembly of a symmetrical yarn biosupercapacitor Cotton yarns were immersed in a boiled Na2CO3 solution (10 mg mL -) for 5 min, followed by water rinsing. The Na2COs treatment and water washing were repeated three t i mes to i mprove the hydrophilicity of the cotton yarns. The hydrophilic cotton yarns were dried in a vacuum oven at 60 °C for 3 h and stored in a zip-bag unti l further use. The hydrophi l ic cotton yarns were wrapped around the as-prepared conductive polymer-coated stainless steel yarns in a clockwise spiral to form electrodes. Two electrodes were arranged in parallel and wrapped with a layer of cotton yarn to form a symmetrical yarn bio-supercapacitor. The surface-wrapped cotton yarns could prevent rela-tive s lippage between the two electrodes. The saturated and residual volumes of the supercapacitors were measured with an electronic bal-ance according to our previously reported method (Xia o et a l., 2022). 2.4. CNT fiber-based pH sensing system An electrochemical polymerization was conducted in an electrolyte solution containing 0.1 M ani l ine and 0.5 M H2SO4 via cyclic voltam-metry to enable the i mmobi l ization of PANI on the CNT fibers. The potential was scanned from -0.2 to 1.0 V for 25 cycles at 100 mVs with the CNT fiber, platinum wire, and Ag/AgCl electrode as the working, counter , and reference electrodes, respectively. After the electrochemical deposition, the functionalized CNT fibers were rinsed with water several times and dried at 40 °C for 20 min. The PANI-coated CNT fibers were used as the fiber-shaped pH sensors. The CNT fiber-based reference electrode was prepared as follows: First, 5-cm-long CNT fibers were uniformly coated with a layer of conductive silver ink, curing at 60 °C for 1 h. Then, chlorination was performed via cyclic voltammetry (CV) between -0.15 and 1.05 V for 4 cycles at a scan rate of 50 mVs -i n an electrolyte solution containing 0.1 M HCl and 0.01 M KCl. A layer of polyvinyl butyral (PVB) was deposited on the chlorinated electrode to minimize the potential drift. 2.5. Cotton-yarn-based sweat-activated battery (CYSAB) The CYSABs were fabricated according to our reported method (Xiao e t a l ., 2022). A cotton yarn was divided into carbon-black-coated cath-ode, sal t bridge , and Zn foil-wrapped anode segments with lengths of 0.5 cm, respectively. Zn foils were cut into smal l rectangular pieces with a length of 1.0 cm and a width of 0.5 cm. The rectangular-shaped Zn foil is t ightly wrapped in the anode region. A 150-pL carbon black suspen-sion (2.5 mg mL -) and a 150-uL bovine serum albumin (BSA, 0.5 wt%)solution were dropped onto the cathode region successively for the construction of the anode. 2.6. Characterization and measurements The morphologies of the capacitor electrodes and the CNT-f iber-based pH sensors were characterized using field-emission scanning electron microscopy (FESEM; JEOL, Tokyo, Japan). The hydrophilicity of the cotton yarns and the supercapacitor electrodes were investigated us i ng a contact angle i nstrument (Model JC 2000D, Shanghai Zhong-cheng Industr i al Corp., China). The Raman spectra of the stainless steel yarns with/without the polymer coat i ngs were measured using a Raman microscope (LabRAM HR Evolution, Horiba Jobin Yvon, France) under an excitation source of 532 nm. CV curves, galvanostatic charge-discharge (GCD) curves, and Nyquist plots were obtained us i ng a CHI660E electrochemical workstation (Chenhua, Shanghai, China). A typical three-electrode system containing a saturated calomel reference electrode and a platinum counter electrode was used to characterize the electrochemical properties of the yarn electrode with artificial sweat as the electrolyte. The long-term GCD cycles of the supercapacitors were tested using a battery testing system (Land CT3002A, Wuhan LAND Electronics. Ltd., China). The areal capacitance (CA, mF cm-) of the yarn electrode was calculated from the GCD curve with the following equation (Hu an g et al., 2022): where I is the discharge current (mA), At is the discharge time (S), AV is the potential window (V), and A is the effective area of the electrode (cm). The surface energy density (EA) and power density (PA) of the devices were calculated according to the following equations: The yarn supercapacitors were subjected to a washing test in a washing machine with water containing 1 wt% detergent at room temperature for 10 min. After being rinsed thoroughly with plenty of water, the yarn supercapacitors were naturally air-dried. After infil-trating a saturated volume of artificial sweat, the supercapacitor was maintained in a test chamber with a temperature of ~25°C and a RH of ~70%. Every 40 min, the CV and GCD were tested with a portable electrochemical workstation with a wireless signal output (PalmSens 4,PalmSens, Netherlands). As to the flexibility test, the yarn super-capacitors were fixed on a flexibil i ty tester (FT 2000, Prtronic, Shanghai MiFang Electronic Technology Co., Ltd., China) for repeated bending assays at a frequency of 0.5 Hz. 2.7. Sweat-activated, self-charging all-in-one sensing textile The CYSAB, SYBSC,CNT-fiber-based pH sensor, and CNT-fiber-based reference electrode were woven into a plain-structured text i le as wefts on a loom. To avoid the shortage of neighboring battery packs, super-hydrophobic cotton yarns were woven as spacers in the self-charging region to separate the battery packs. The CYSABs and SYBSCs were connected in a series-parallel configuration to power a mini wireless electrochemical analyzer (BioSYS-P15E, Refresh Inc., China) for data collection and t ransmission f rom the pH sensing system. The pH sensing were measured using the BioSYS-P15E under an OCPT mode with a sampling interval of 0.2 s. A DC-DC power supply boost module was used to convert a 0.9-5 V output voltage to 5 V. 2.8. On-body demonstration The on-body tests were approved by the SWU human research ethics committee. Al l participants provided written, informed consent before participation. Three volunteers, including a female adult, a male adult,and a 6-year-old child, were recruited for the on-body demonstration.The sweat-activated, self-charging sensing textile was integrated into the back of a T-shirt, worn by a volunteer. The volunteer started to ex-ercise on a spinning bicycle at a speed of 7.5-8.0 km/h in an environ-ment with a temperature ranging from 32 to 36°C and a RH of~70%. The whole testing process was recorded in real time by a video camera.The sweat secreted by the volunteer could activate the self-charging units to power the mini electrochemica l analyzer for sweat pH moni-toring. The signals were transmitted wirelessly to a mobile phone to real-time exhibit the change in the sweat pH value. 3. Results and discussion As a 1-D conductive substrate wi t h superior mechanical strength,stainless steel yarn has been widely employed to construct a yarn-shaped triboelectric nanogenerator. In the present work, it was used as the current collector to immobil i ze active materials in yarn-based super-capacitors. Conductive polymers have been chosen as the active mate-rials to construct the sweat-based yarn biosupercapacitors owing to the excellent electrical conductivity, high theoretical capacitance, wide potent i a l window, good biocompatibi l ity, and expected flexible features (Te n g e t al., 2020; W an g e t a l ., 2022). To achieve a high capacitance, the electrochemical deposition of PPy and the dip-coating of PEDOT:PSS were repeated (F ig . 2a and S1). The yarn coated with a bilayer of PPy/PEDOT:PSS exhibits a speci f ic capacitance of 180.5 mF cm,which is much higher than those obtained from the yarns modified with three layers of PPy or PEDOT:PSS only (Fi g. S2). The PPy/PEDOT:PSS electrode shows a higher quasi-rectangular CV curve (F ig . S 2e ) when compared to electrodes modified with PPy or PEDOT:PSS alone, indi -cating that it has a greater electrical double capacitance. Therefore, the electrochemical double layer charging step may be impacted by the combination of PPy and PEDOT:PSS. Given that the PPy/PEDOT:PSS electrode’s surface is significantly rougher than t hat of the PEDOT:PSS electrode (Fi g s. S 2b a nd S 2d ), the increased specific surface area may be responsible for the significantly higher electrical double capacitance of the PPy/PEDOT:PSS electrode. I n the bilayered fi l m, the PPy and PEDOT:PSS chains may i nteract with each other to forma double-network structure (Fi g. S3). In comparison to the non-porous materials, the micrometer-scale channels between the twisted fibers could spontaneously wick electrolytes and i nks for highly ef f icient modification of the polymers in the yarns (Fig . 2b). The cross-sectional FESEM and EDS elemental mapping images of the yarn coated with 4bilayers of PPy/PEDOT:PSS show the existence of sulfur (S) and nitrogen (N) elements, which could be attributed to PEDOT:PSS and PPy,respectively (Fi g. 2c). Differently from the regular scratches on the pristine stainless steel fibers, a lot of micro-scale spots could be observed on the modified ones (F ig . 2d). Moreover, the Raman spectrum of the modified yarn (F ig. 2e) displays the characteristic peaks for both PPy (1005, 1084, and 1607 cm-) and PEDOT:PSS (1468cm-). The data verify the successful immobilization of the active materials on the conductive yarns via layer-by-layer deposition. To evaluate the capaci t ive behaviors of the PPy/PEDOT:PSS-coated yarns, the CV, GCD curves, and Nyquist plots were measured in a three-electrode system with art i ficial sweat as the electrolyte (F ig . 2f , g,and S4). The quasi-rectangular CV curves at a scan rate of 5 mV s -and the symmetrically triangular GCD curves at a current density of 1 mA cm-2 i ndicate the good capacitive performance and excellent revers-ibility of the polymer-f unctionalized yarns, respectively (F igs . S4a a n d S 4b ). As the bilayer number increases, a higher speci f ic capacitance could be achieved. The Nyquist plots show a straight line with a large slope i n the low-f requency region and a short Warburg region i n the medium-frequency range, suggest i ng the superior capacitive properties of the yarns and the fast charge transfer rate at the active material- a electrolyte interfaces, respectively (Fi g . S4c ). After 4 rounds of layer-by-layer i mmobilization , the polymer density and the specific capacitance could r each 1.9 mg cm-" and 746.2 mF cm-, respectively. Since the enhancement of specific capacitance slows down after 3 rounds of modif i cation, the yarns coated with 4 bi l ayers of PPy/PEDOT:PSS were chosen as the optimal electrodes for the preparation of bio-supercapacitors. The shape of the CV curve of a 4-bilayer-polymer-modi-fied yarn is gradually distorted from the rectangle to the spindle as the scan rate i ncreases from 10 to 100 mVs - (F ig. 2f ). The GCD curves of the polymer-coated yarn exhibit ideal l y symmetrical triangles at current densities ranging from 0.5 to 5 mA cm, implying the high Coulombic efficiency and the great reversible Faraday response. Notably, an areal capacitance of up to 775.6 mF cm-2 could be achieved at a current density of 0.5 mA cm-2. Even when t he current density increases to 5mA cm-2, the value could be maintained at 518.1 mF cm-²(66.8%)(Fi g . 2g). The above resul t s indicate that the yarn modified with 4 bilayers of PPy/PEDOT:PSS possesses excellent capacitive properties in artificial sweat and could be uti li zed as a 1-D electrode for fabricating yarn-shaped sweat-activated biosupercapacitors. Two PPy/PEDOT:PSS-coated stainless steel yarns were assembled in a symmetric structure with hydrophi l ic cotton f ibers as the separating layer to prepare a sweat-based yarn-shaped supercapacitor (Fi g. 3a).First, a thin layer of hydrophilic cotton yarn was densely wrapped around an active material-modified yarn to produce a 1-D electrode.Then, two electrodes aligned in parallel were wrapped with another layer of hydrophilic cotton for the construction of a symmetric super-capacitor. The cotton fibers in t he supercapacitors could spontaneous l y infiltrate and store the electrolyte solution for efficient activation of the devices (Fi g .S 5). They may also greatly improve the skin affinity of the yarn-shaped supercapacitors for body-contact wearable applications.The twisting angle (a) between the cotton yarn and the electrode core was controlled to be less than 15° to ensure the dense wrapping of the Fig. 3. Electrochemical properties of the SYBSCs. (a) Scalable fabrication. (b) I l lustration of a spirally twisted cotton yarn. (c) Cross-sectional photograph of an SYBSC. (d) From PPy/PEDOT -modified yarns to SYBSCs. (e) CV curves (i), GCD curves (ii), specific capacitances (iii ), and Ragone plots (iv) of the SYBSCs. (f )Photographs (i), CV curves (ii), GCD curves (ii i ), and specific capacitances (iv) of an 8-cm-long device in the l i near, U-shaped, c i rcular, and tr i angular states (T he data obtained from three independent experiments are presented as the mean±standard deviations). (g) (i) An 8-cm-long device at the releasing and bending states; (i i )GCD curve of an SYBSC under repeated bending; (i i i) Capacitance retention and Coulomb efficiency of an SYBSC during 10,000 cycles of bending. cotton fibers (Fi g . 3b and c). The surface modification and device fabrication processes could be integrated into the conventional spinning techniques for large-scale production. After the surface cotton wrapping,the color of the polymer-coated yarns changed from black to white (Fi g . 3d and S6). The as-prepared yarn electrodes and the SYBSCs could tolerate 30 min of ultrasonic treatment without significant changes to their structures (F i g. S 7a ). Moreover, the SYBSC could be stored in water for more than 120 days without any damage to its surface coating layer or the symmetric structure (F ig. S7b ), showing its extremely high sta-bi l ity and long-term storage capacity. After the structural optimization (Fi g. S8), the 4-cm-long SYBSCs with one layer of cotton separator were soaked with artificia l sweat for the measurement of their electrochemical properties. The super-capacitors exhibit nearly rectangular CV curves at low scan rates, indi-cating good capacitive behavior (F ig .3e). The ideally symmetrical GCD curves at current densities from 0.5 to 5 mA cm-reveal the excellent reversibil i ty of the activated SYBSCs. As the current density increases from 0.5 t o 5 mA cm, the specific capacitance of the SYBSC gradually decreases. At the current density of 0.5 mA cm-, an areal capacitance of 343.1 mF cm-2 could be obtained. Even at the discharge current density of 5 mA cm-2, the areal capacitance could remain at 255.6 mF cm-2.The Ragone plots show the correlation between t he energy density and power density of the SYBSCs. When the power density increases from 200 to 2000 pW cm-, the corresponding energy density decreases from 30.5 to 22.7 pW h cm-. The electrochemical performance of the as-prepared SYBSCs is comparable to the sweat-based biosupercapacitors reported i n previous studies (T ab le S3). In comparison to the energy textiles reported previously, the as-prepared biosupercapacitors possess better weavability, washability, reusability, and higher power output (T a bl e S 4). Therefore, the SYBSCs are expected to serve as stable power sources for the next generation of portable and wearable electronics. Since the SYBSCs are designed as the building blocks of electronic textiles, flexibility is of great importance for their weavability and wearable applications. Taking advantage of the 1D structure, the SYBSCs could be bent i nto straight, U-shaped, circular, and triangular states without any obvious mechanical damage. No significant changes in the shapes of the CV and GCD curves could be observed for the devices at t he above bending states, i mplying the superior mechanical stability of the SYBSCs (F ig . 3f). During the repeated bending-releasing cycles,the electrochemical properties of the SYBSCs were also monitored in real time. Although there is a slight fluctuation in the CV curve, the rect-angular shape remains the same as that of the device in its static state (Fi g . S 9). As to the GCD tests, the repeated bending does not cause any remarkable impact on a single charge/discharge process (Fig. 3g and Video S1). The charge-discharge cycles (162 cycles) were continuously conducted on an SYBSC at a current density of 1 mA cm-2during 10,000times of bending. The reversibility of the supercapacitor can be main-tained during the whole process, but a reduction in the charge/discharge t i me and a voltage drop in the discharge curve occur after 10,000 cycles of bending (F i g. S9). The capacitance of the SYBSCs gradually declines during the first 2000 cycles of bending. After that, the capacitance retention rate i s kept at around 68% of its original level as the bending times further increase from 2000 to 10,000 (F ig. 3g). In addition, the washability of the SYBSCs was also investigated with a commercial washing machine in an aqueous solution containing 1 wt% detergent.The capacitance of the device can be maintained without change after 17 washes. Even after 25 washing cycles, the capacitance retention rate could still reach 73%(F ig. S 10). The performance degradation caused by bending and washing may be attributed to the partial detachment of the active materials from the electrodes. The as-prepared SYBSCs possess excellent flexibility and superior tolerance to mechanical deformation,making them ideal as energy storage units in sweat-activated self-charging textiles. It should be noted that the SYBSC has a bending ri-gidity that is more than 400% higher over cotton yarn (F i g . S11). The high bending stiffness may be caused by the stainless steel yarn and the twisting structures. Supplementary video related to this article can be found at htt p s://d o i .o rg /10.1016/j.b io s.2023.115389 The ionic strength and volume of human-secreted sweat greatly depend on the individual's health status, environmental temperature,and exercise intensity . Therefore, it is necessary to investigate their impacts on the electrochemical performance of the SYBSCs. The original artificial sweat was diluted at 1 fold (1×), 2 folds (0.5×), 5 folds (0.2x), and 10 folds (0.1 ×) to obtain the electrolytes with various ionic strengths. The change in the ionic strength of the electrolyte does not induce a significant shape alteration on the CV curves. However, both the CV curve area and the discharge t ime gradually decrease with the enhancement of the dilution fold, indicating a slight reduction in the speci f ic capacitance. After calculation, i t can be found that the speci f ic capacitances corresponding to the 1 × and 0.1 × art i ficia l sweats are 338.0 and 285.5 mF cm-, respectively. The intersections of the Nyquist plots with the real axis show that the ohmic resistance of the device rises wi t h the decrease of the ionic strength (F ig . 4a). This phenomenon could be attributed to the reduction of ionic conductivity in the electrolyte solution. Although a specific capacitance of 285.5 mF cm-2could be achieved with 0.1 x art i ficial sweat, the high resistance and the corre-sponding voltage drop in the charge/discharge transition should be considered during the wearable applications of the SYBSCs. Since t he saturated volume of a 4-cm-long SYBSC was determined to be approximately 100 pL, the electrochemical performances of the SYBSCs were tested with 10, 20,50, and 100 uL of artificial sweat. The supercapacitor could be activated with only 10 pL of artificial sweat.When the volume increases from 10 to 100 uL, the CV curve gradually changes from a spindle shape to a near rectangle shape, accompanied by an enhancement of the CV curve area. Similarly, the charge-discharge 8duration significant l y increases with the electrolyte volume. Based on the GCD curves, the specific capacitances of the 10 pL- and 100 pL-sweat-activated SYBSCs were calculated to be 27.4 and 320.9 mF cm-2.respectively. As the volume of artificial sweat increases, the voltage drop decreases significantly. The intersection of Nyquist plots with the real axis and the semicircle i n the high-frequency range reveal that a large volume of artificial sweat leads to low internal resistance and high charge transfer efficiency (Man j akk al e t a l ., 2020; H u a n g et a l ., 2022),which could explain the high performance of SYBSCs observed at large sweat volumes (F ig. 4b). Since the SYBSCs will be exposed to the outside environment during practical wearable applications, the sweat volume stored in the device may continuously reduce due to water evaporation. To explore the ef-fects of evaporation, the devices were infi l trated with 100 pL of ar t ificial sweat while standing at ambient condi t ions (T=25°℃,RH=70%) for 0-240 min. It can be observed from the electrochemical data that the effects of evaporation could be divided into two stages. For the f i rst 80min, there are no significant changes in either t he CV or discharge curves. However , after 80 min, the CV curve gradual l y alters from a rectangle to a spindle shape. Moreover, the discharge t i me of the device decreases from 125 to 48 s, with a significant increase in the voltage drop from 0.07 to 0.32 V. The data suggest that water evaporation for more than 80 min could result in the remarkable performance degra-dation of the electrolyte-infiltrated SYBSCs. The capacitance retention rate and residual water volume in the devices were also displayed against the evaporation time to indicate the decreasing trend. As the evaporation time increases, the residual water in the devices reduces l i nearly, implying a constant water evaporation rate. Interestingly, the capacitance stays stable for the first 80 min, then decreases linearly. At 80 min, the volume of the residual water in the device is ~60 pL, which should be the minimum volume of the l iquid electrolyte required to ful l y maintain the capacitance of the SYBSCs (F i g. 4c). The increase of the body and environmental temperature may accelerate the migration of ions in the sweat , leading to an enhanced performance of the SYBSCs (Hu ang e t a l ., 2014; M a s ara p u e t a l ., 2009). Furthermore, by altering the sweat evaporation from the activated devices, the environmental tem-perature could also have an i mpact on the performance of the SYBSCs. Fig. 4. Effects of the sweat changes on the SYBSC performance. (a) CV curves (i), GCD curves (ii), and Nyquist plots (iii ) of the SYBSCs activated with the 1.0x, 0.5x,0.2x, and 0.1x artificial sweat. Inset in (i i ) shows the speci f ic capacitances at different dilution ratios. (b) CV curves (i), GCD curves (i i), and Nyquist plots (i i i ) of the SYBSCs activated with different volumes of artificial sweat. Inset in (ii) shows the specific capacitances at different volumes of artificial sweat. (c) CV curves (i),discharge curves (i i), as well as residual volume and capacitance retention (iii) of the artif i cial sweat-soaked devices after evaporation for different t imes. Based on the results, it can be concluded that the evaporation of the yarn-absorbed electrolyte could significantly affect the SYBSCs’ perfor-mance and needs to be considered i n thei r practica l applications. To power flexible electronic devices for healthcare and motion monitoring, a high-performance textile-based self-charging system is extremely des i rable. The recently reported cotton yarn-based sweat-activated battery (CYSAB) was combined with the as-prepared SYBSC in the present study to create a textile-based sweat-activated self-charging system (F ig . 5a). When the discharge currents of 50 and 100 uA were used, the output voltages of the sweat-activated CYSABs could be kept at constant values (F ig . S13). The batteries could be parallel-connected to enhance the power output and working current. The maximum power of a pack with t hree parallel-connected batteries is 0.43 mW, which i s three times higher than that of a single CYSAB (F ig . 5b). When an SYBSC is series-connected with a single CYSAB in the presence of sufficient arti-ficial sweat, its voltage immediately rises and finally reaches the plateau of 0.63 V after 1000 s, showing the successful charging of the super-capacitor with the sweat-activated battery. However, if an SYBSC was charged with a battery pack containing 2 or 3 parallel-connected CYSABs, the voltage could rapidly increase to 0.7 V within 372 or 301 s, respectively (F i g. 5c). The battery pack could charge an SYBSC more efficiently than a single battery. Taking the capacitor performance,charging time , and cost into account, two paral l el-connected CYSABs were chosen to charge one SYBSC i n the design of a texti l e-based hybrid energy system. The pulse-type discharge tests (Lv et a l.,2021b ) were conducted at currents ranging from 0.2 to 3.0 mA to show the output performance of the energy supply units. The 2 parallel-connected CYSABs could repeatedly discharge at currents of 0.2 and 0.5 mA with the corre-sponding output voltages of 0.72 and 0.39 V, respectively. However,when the current i ncreases to 1.0 mA, the discharge voltage declines to less than 0.1 V, and the discharge process stops at the 6th cycle. At discharge currents higher than 1.0 mA, the battery pack cannot work properly (Fig .5d). The high internal resistance of the CYSABs may result in poor output performance, which greatly hinders their applications in triggering high-power electronic devices. As shown in Fi g . 5e, the pulse-type discharge patterns greatly change when an SYBSC is series-connected with the battery pack to form a self-charging energy unit. The discharge could be performed at currents ranging from 0.2 to 3.0 mA, last i ng for 8 circles. The output voltages at 0.2,0.5, and 1.0 mA are 0.71, 0.55, and 0.40 V, respectively, which are much higher than those obtained from the battery pack. In addition, each discharge step was followed by a gradual recovery of the voltage, verifying the suc-cessful charging of the SYBSC by the CYSABs. Although the voltage cannot go back to the original levels of 2.0 and 3.0 mA, the unit could sti ll support the next round of discharge. The results show that the sweat-activated self-charging units containing 1 SYBSC and 2 CYSABs are capable of supporting high-current discharge and high-power out-puts. To further demonstrate the feasibi li ty, the battery pack and the sel f -charging unit were connected with a voltage regulat i ng module (operating current > 100 uA) to i lluminate an LED (operating voltage:2-2.2V,respectively. The battery P pack containing two paral l e l-connected CYSABs cannot power the LED due to i ts low output.However, after 6 min of charging, the self-charging unit could trigger the LED to emit a very strong light (Fi g. 5f and Video S2). Supplementary video related to this article can be found at htt p s ://doi .o rg /10.1016/j.bi os .2023.115389 The SYBSCs could be connected in series-parallel configurations to meet the requirements of practical applications in electronic textiles. In comparison to a single SYBSC, the series connection of the SYBSCs provides a higher output voltage, while their paral l el connection leads to a lower internal resistance (F i g .S 12). Therefore, the f lexible 1-D CYSABs and SYBSCs could be integrated into the textiles via the conventional weaving technique to create sweat-activated, self-charging energy fab-rics. As shown in F ig . 5g, 16 CYSABs and 8 SYBSCs were employed as the wefts to weave a plain-structured band together with cotton yarns. The Fig.5. Integration of the SYBSCs with the CYSABs for sweat-activated self-charging. (a) Circuit diagram of the integrated self-charging system. (b) Power data of the CYSABs connected i n parallel . (c) Voltage changes of the SYBSCs during the charging process. (d) Discharging performance of two parallel -connected CYSABs at currents of 0.2, 0.5, 1, 2, and 3 mA, respectively. (e) Discharging performance of an integrated power unit containing 2 parallel-connected CYSABs and 1 SYBSC at currents of 0.2, 0.5, 1, 2, and 3 mA, respectively. (f) LEDs powered by two parallel/series -connected CYSABs and the integrated se lf -charging system. (g) Construction of a sel f -charging text i le containing the SYBSCs and CYSABs via the weaving technique. as-prepared band has four power supply units, each with four parallel-connected CYSABs and two parallel-connected SYBSCs coupled in se-ries (F ig . S14a ). By tailoring the hydrohylicity and the structure of the yarns, the sweat-transport rate may be increased. The hydrophilic and hydrophobic regions on the fabrics could be engineered to faci l itate the accumulation of sweat i n the designed area for efficient activation of the hybrid energy system (Fi gs . S 14c a n d S14d ). The series-connected power supply units are separated by hydrophobic regions to prevent short-circuiting in the presence of excessive sweat. The hybrid energy band was used to power a mini electrochemical analyzer for real-time human sweat sensing in the following on-body tests. Sweat pH is an indicator of the salt-water balance of the human body during exercise (Xu et a l ., (2021). In the on-body tests, 1-D pH sensors were prepared by electrodepositing a l ayer of polyaniline (PANI), a proton-selective material, on the carbon nanotube (CNT) fibers. The Ag/AgCl-modified CNT fibers were also fabricated as the reference electrodes (F ig. 6a, b, and S13b). During the sensing process, the pro-tonation and deprotonation of PANI lead to a change in the open circuit potential (OCP) versus the reference electrode (F i g. 6c). A l i near cor-relation between the OCP and pH could be achieved i n the pH range of 4.0-8.0 with a sensitivity of 65.89 mV pH-(F i g. S16), which is slightly higher t han the Nerst limit. This phenomenon may be caused by the use of a“quas i -reference”electrode , an Ag/AgCl wire, in the system. The pH change of the solution may induce the potential variation of the “qua-si -reference"electrode, further resulting in the sensitivity beyond the Nerst l i mit. The recovery rates of the sensors varied from 98.8% to 107.6% (T ab le S2). The f iber-shaped pH sensor and Ag/AgCl reference electrode were sewed into the above-mentioned hybrid energy band to form an all-i n-one electronic textile, in which the sweat-activated ,self-charging energy units power the mini-analyzer for sweat pH sensing and wireless data transmission (F ig . 6d, e, S13 and Video S3). In comparison to the conventional rigid systems, the conformable and skin-f riendly all-in-one e-texti l e could be easily integrated into a T-shirt for the self-powered real-time analysis of the pH of the volunteers'sweat during exercise (F ig . 6a). A metal magnetic button was f i xed on the T-shirt as a switch to control the discharge of the supercapacitors for Fig. 6. On-body demonstration of a sweat-activated, self-charging textile for sweat pH sensing. (a) A female volunteer with a sweat-activated, sel f -charging sensing text i le on her back under the test. (b) A mini-analyzer powered by t he sweat-activated, sel f -charging units after cycling for 10 min. (c) Working principle of the yarn-shaped pH sensor. (d ) Circuit diagram of the mini-analyzer and the sel f -charging units. (e) Working flow of the swea t -activated, self-charging sensing system. (f)Changes in the sweating rate and the charging/discharging cycles during the ent i re on-body test i ng process. (g) Real-t i me monitoring of the sweat pH of three volunteers during exercise. powering the mini-analyzer (Fig . S 17). At the states of Bluetooth connection and measurement initiation, the operating current should be about 3 mA. However , at the standby and continuous measurement states, the operat i ng current should be altered in the range of 0.06-0.5mA (Fig . S15). As shown in F ig. 5d, the CYSABs could not deliver a current greater than 2 mA. Thus, the SYBSCs should play a dominant role i n the hybrid system at the states of analyzer triggering and mea-surement initiation. In the rest states, the CYSABs may maintain the working of the analyzer . Three volunteers wearing the all-in-one system were asked to exercise on a spinning bicycle at a speed of 7.5-8.0km/h for 25 min in an environment with a temperature ranging from 32 to 36°C and a relative humidity of 70%. All volunteers started to perspire within 4 min. As the cycling duration increased, the volunteers sweated more heavily. The body-secreted sweat could be absorbed by the all-in-one electronic band to activate the CYSABs and SYBSCs for the init i alization of the self-charging process. When the switch was turned on, the energy stored in the supercapacitors could be ut il ized to trigger the mini-analyzer for real-t ime sweat pH monitoring and wireless data transmission to a smartphone (F ig. S 19). After several minutes of operation, the switch was turned off, enabl i ng the next round of self-charging. The charging-monitoring cycle was repeated to achieve intermittent sweat pH analysis. Interestingly, the sweat pH could stil l be sensed with the all-in-one system when the volunteers stopped the ex-ercise. This phenomenon may be attributed to the perspiration sustained after the high-intensity exercise and the sweat stored in the hydrophilic textile (F ig . 6f). Supplementary video related to this article can be found at ht t ps://d o i.o rg/10.1016/j.bios.2023.115389 During the monitoring, the pH of volunteer No. 1’s sweat gradually increases, with average pH values of 5.3, 5.4, and 5.9 for the three measurements, respectively. However, in the real-time sensing process,volunteers No. 2 and No. 3 show a decreasing trend in sweat pH. The final pH values for volunteers No. 2 and No. 3 were 5.7 and 5.4,respectively. The measured pH values are all within the normal physi-ological pH range of human sweat , which is consistent with the data reported previously (W ang e t a l., 2018; T e r se -Thak o or e t a l., 2020). The variation in pH among the volunteers’ sweat may be caused by their fatigue degree and health status. The results strongly prove that the sweat-activated all-in-one sensing textile could be successfully used as a very promising wearable tool to monitor sweat pH and wirelessly transmit data in real-time for the timely evaluation of human exercise intensity. To e evaluate tthe biocompatibility of the as-prepared bio-supercapacitors, the L-929 f ibroblast cells were co-cultured with a PEDOT :PSS/PPy-modi f ied electrode and a SYBSC for 5 days, respec-tively. The transparency and color of the culture media do not signifi -cantly change during the culture process (F i g. S20a ). The cel l viabili t ies of the electrode-and SYBSC-treated samples could be kept at levels close to 100% compared to the control group (F ig. S 20b). The fluorescent images (Fi g . S20c ) demonstrate that the treated samples’cel l densi t ies are similar to those of the control group. Additionally, the in vivo on-skin tests show that the sel f -charging text i le containing the CYSABs and SYBSCs does not result in overt irritation during the observation period (F ig .S21). 4. Conclusions We have developed a 1-D, biocompatible, and sweat-activated bio-supercapacitor as an alternative to conventional energy storage devices for the construction of a sweat-activated, self-charging sensing textile.The SYBSC was assembled with two cotton-fiber-wrapped PPy/PEDOT:PSS-modified stainless-steel yarns in a symmetric mode. The SYBSC exhibits a high areal capacitance (343.1 mF cm-2 at 0.5 mA cm-3),balanced energy density (30.5-22.7 pW h cm), and power density (200-2000 pW cm-2). The device capacitance could be retained at sat i sfactory levels after 10,000 times of bending with continuous charge-discharge cycles (68%) and 25 cycles of machine washing (73%). The SYBSCs could be connected with the CYSABs to create sweat-activated hybrid energy units, in which the SYBSCs could be charged by the activated batteries to deliver a high power output. The SYBSCs, the CYSABs, and the pH sensing fibers were woven into a plain, structured textile in the presence of a mini-analyzer to achieve a sweat-activated,self-charging pH sensing system. In the on-body tests, the sweat secreted by the volunteers under cycling could activate the body-attached al l -in-one sensing text i le, in which the analyzer was powered by the self-charging units to initiate real-time data collection and wireless transmission, to realize the sweat pH monitoring during exer-cise. The as-prepared yarn-based systems are more compatible with practical applications as compared to the previously reported sweat-based hybrid self-charging systems because of their excellent weav-abi l ity, washabil i ty, and reusability (T a b le S 1). This work may not only develop a yarn-shaped sweat-activated supercapacitor as a weavable energy storage device in textile electronics but also provide a design of textile-based all-in-one sensing systems for wearable applications. CRediT authorship contribution statement Gang Xiao: contributed equally to this work, conceived the idea and designed the experiments, conducted al l the characterization and mea-surements, performed the data analysis, prepared the manuscript. Jun Ju: contributed equally to this work, conducted all the characterization and measurements, prepared the manuscr i pt. Min Li: helped with on-body demonstrations and support i ng movie recordings. Huajun Wu:helped with on-body demonstrations and supporting movie recordings.Yihao Jian: helped with on-body demonstrations and supporting movie recordings. Wei Sun: provided valuable suggestions during the whole project. Wei Wang: provided valuable suggestions during the whole project . Chang Ming Li: provided valuable suggestions during the whole project. Yan Qiao: supervised the project, prepared the manu-script. Zhisong Lu: conceived the idea and designed the experiments,supervised the project, performed the data analysis, prepared the manuscript. Declaration of competing interest The authors declare that they have no known compet i ng financial interests or personal relationships that could have appeared to influence the work reported in this paper. Data availability Data wil l be made available on request. Acknowledgements This work was f inancially supported by the Innovation Research 2035 Pilot Plan of Southwest University (Grant No. SWU-XDPY22014),the National Natural Science Foundation of China (Grant No.22272130), and the Specific Research Fund of Innovation Platform for Academicians of Hainan Province (Grant No. YSPTZX202126), and the Innovation Platform for Academicians of Hainan Province. Appendix A. Supplementary data Supplementary data to this article can be found online at ht t p s ://do i .o r g/10.1016/j .bio s.2023.115389. References Band odk a r, A.J., L ee, S .P., H u ang, I ., L i , W., Wa n g, S ., Su , C.J ., Jean g, W.J ., H a n g, T.,Meht a, S., Ny be rg, N., G ut r u f, P ., C hoi , J ., Koo , J., Reed e r, J.T., T s e ng , R., G h a ff ari, R ., R ogers, J .A., 2020. Na t . E l ec t ron. 3 (9), 554-562. Ca i , S ., Xu, C., Ji ang , D., Y uan , M., Z hang, Q. Li , Z ., Wang , Y ., 2022. Na n o Ene r gy 93,106904. C he n , G ., Zhao ,X., And al ib, S., Xu , J., Zhou , Y ., Ta t , T ., Lin , K., Che n ,J ., 2021a . M at t er 4(11),3725-3740. C he n , G ., Au, C ., Ch e n , J ., 2021b. T r e nds Biotech n ol . 39 (10),1078-1092. Ch en , C., Fe n g, J., L i , J ., Gu o , Y ., S hi , X., P eng , H ., 2022a. C h em . R ev. 122(3),3259-3291. C h en , G ., Xiao , X ., Zhao, X ., Tat , T ., B i ck, M., Che n , J ., 2022b. Chem. Rev . 122 (3),3259-3291. D o n g, K., P e n g, X ., Wa n g, Z.L ., 2020. A d v. Ma te r . 32 (5), 1902549. Gao, Y ., Ch o, J .H., Ry u , J ., C h oi , S., 2020. Na n o En e rgy 74, 104897. G a o , Y., Reza i e , M., Ch oi , S ., 2022. N a n o E ne r g y 104, 107923. He , C ., Cheng , J., Wu, C., W ang, B., 2022. Adv . Fiber Ma t er. 5, 130-137. H u an g , N ., K ir k, D .W., T h o r pe , S.J ., Li an g, C., X u, L ., Zh ang , S ., L i, W., S un , M., 2014. EC S Tra ns. 61(18), 9.9,H u a n g , Q ., Wa n g, D ., Hu , H ., S h a n g, J ., C hang, J ., X i e, C ., Yang, Y ., Lepro , X ., Bau g hm an, R .H ., Zheng, Z., 2020. Ad v . F un c t. Ma t er . 30 (27),1910541. H u an g, H., Zh ao,Y ., C o n g, T ., L i , C ., We n , N ., Zuo, X., Guo,Y ., Zh an g , H., Fan , Z ., Pa n , L ., 2022. Adv. F u n ct . Ma te r . 32 (22), 2110777.J u , J ., X i ao, G ., Jian, Y ., Wu , L ., Su n, W., Wang, W., L i, C .M ., Q iao, Y ., Lu , Z.,2023.Nano Ener gy 109, 108304. Kwon, C.H ., Ko, Y ., S h in, D ., Kwon, M., Park, J ., Bae , W.K., Lee , S.W., Cho ,J ., 2018.Na t .Commun .9(1),4479. L i , X., L i u , R., X u , C ., B a i , Y ., Zhou , X., Wa n g, Y., Yu a n, G., 2018. Adv . F u nc t . Ma te r . 28(22),1800064. L i ao , M., Wa n g, C ., H o ng, Y., Zha n g, Y., Ch e ng, X., S u n , H., Hu a ng, X., Ye , L., Wu, J .,Sh i , X., Ka ng , X ., Z ho u , X., Wa n g , J ., Li, P ., S un , X ., Ch en , P., Wang , B ., Wang, Y .,Xia, Y ., C h en g, Y., Pe ng, H ., 2022. Nat. N a n o t e ch no l . 17 (4), 372-377. ,Z H L i ma , N., Bap t ista , A .C ., Fa u stino, B.M.M., T a bord a , S., M a r q u es , A., Fe rr e i r a , I.,2020.S c i . Re p. 10 (1),7703. L i ba n o ri, A ., C h e n, G ., Z hao , X ., Z h o u, Y ., Ch e n, J ., 2022. N a t. E lec tr o n. 5 (3), 142-156. L i n, R., Kim , H.-J ., Ac h avanan th adi t h, S ., Xiong, Z., Lee , J .K.W ., K ong, Y.L., H o, J .S.,2022. N a t . C ommu n .13 (1),2190. L iu , Z ., Mo , F ., L i , H ., Z h u, M., W a n g, Z ., L i ang, G., Zh i , C., 2018. Smal l Met ho d s 2 (11),1800124. L i u , Y ., H uang, X., Z ho u , J ., L i, J., Ne j ad, S .K ., Yi u, C.K., Li , H ., Wong , T .H., Pa rk , W., Y ao , K ., Zhao, L., Shi , R., Wang , Y., D ai , Z., Yu, X., 2022a . Na n o En e rgy 92, 106755.Liu , Y., Huan g, X ., Zhou, J ., Yi u , C.K., Song , Z., Huan g , W., N e j a d , S.K., Li , H ., Wo n g , T. H., Y a o , K., Zhao , L ., Y oo, W., P ark, W., Li , J ., Hu an g, Y., Lam, H .R., S o n g, E .,Gu o , X ., Wang, Y., Da i, Z., C hang, L ., Li, W.J ., Xi e , Z ., Yu , X., 2022b. A d v . Sci. 9 (9),2104635. Luo , Z., Li u, C ., Fan , S., 2019. J . M a t er . Che m. 7 (8), 3642-3647. L u o , Z., Wan g, Y ., K o u , B ., Li u, C ., Zh a n g, W., Ch en , L ., 2021. E n e rgy Sto r age Ma t e r. 38,9-16. Lv , J ., J ee r a pa n , I , T e h ran i , F ., Yin, L ., Si l va -Lop e z, C .A ., Jang , J.-H ., Josh uia , D .,Sh ah , R ., Lia n g , Y ., X ie, L ., Soto , F., C h en , C., Ka r s h alev , E ., Ko n g, C., Yang , Z.,Wan g, J ., 2018. En ergy E n v i ro n . Sci . 11 (12),3431-3442. Lv, J ., T h angavel, G ., L i , Y., Xiong, J ., Gao, D ., C io u, J ., Tan, M.W.M., Aziz, I., Chen, S.,Chen , J., Zho u , X ., P o h , W.C ., L ee, P.S., 2021a . Sci . Ad v . 7 (29), e a bg 8433. L v, J., Yi n, L ., C h en , X., Jee r a p an , I ., S i l v a, C .A ., L i , Y., L e , M., L i n , Z., Wang, L ., Tr i fo no v, A ., Xu , S ., C osnier , S., Wa ng , J ., 2021b. A dv . Fun c t. M a t er . 31(38),2102915. Ma, W., Z h ang , Y., Pa n , S., Ch en g, Y., Shao , Z ., X iang , H., C he n , G ., Z hu , L., Weng , W.,Bai, H ., Zhu , M., 2021. C h e m. Soc. R ev . 50 (12), 7009-7061. M a, S., Wa n g, X., L i, P., Y ao , N., Xi a o , J., L i u , H., Zhang, Z., Yu , L ., Tao, G ., L i , X., Tong, L., Z h ang , L ., 2022. Ad v . F iber Ma ter. 4 (5),1108-1117.Manja kk al, L., P u l l a n chiyodan , A ., Yogeswaran , N., Hosseini , E .S .,Da hiya,R ., 2020. Ad v .Mater. 32 (24),1907254. Manja k ka l , L ., Y i n , L ., N a than, A., Wa n g, J ., D ahi ya, R ., 2021. Adv. Ma t er. 33 (35),2100899. Masarapu , C., Ze ng, H .F ., H u ng, K .H ., W ei , B., 2009. ACS Na no 3 (8), 2199. Men g , K., X i ao, X ., Wei , W., C he n , G., N as h al i an, A., S h en , S ., X i ao, X., C he n , J., 2022.Ad v . Ma te r . 34(21),2109357. O rtega, L., Ll o r e l l a, A ., E sq u ive l, J .P., Sa b ate,N., 2019. Mic r o s ys . N a n oen g. 5 (1), 3.Se l vam, S., Y i m , J .-H., 2023. J . P owe r So ur ces 556, 232511. Se l va m , S., Pa r k, Y .-K ., Y i m, J .-H., 2022. Adv. Sc i . 9 (25),2201890. Sun , M ., Gu, Y ., Pei , X., Wang , J ., Li u , J., Ma , C., Bai , J ., Zhou , M ., 2021. Nano Energy 86,106061. Te ng , W ., Z ho u , Q ., Wang , X ., C he, H., Hu , P., Li , H., W a n g,J ., 2020. C he m . E ng . J. 390,124569. T ers e -Th ak oor , T., Pu n jiya , M., M a th a ru , Z., L y u, B., Ahmad , M ., G i les , G .E ., O wyeu n g , R ., A l a i mo , F., Sh ojaei Bag hi ni , M ., B r un ye, T .T ., So n kusale , S ., 2020. Npj F l ex. El e ct ron . 4(1),18. T o n g, X., Sh eng , G ., Y an g , D., L i , S ., Li n, C.-W., Zha n g, W., C h en , Z ., We i , C ., Y a n g , X.,Sh e n, F ., Sh ao, Y., W ei , H., Zh u , Y., Su n, J., Kaner , R.B ., Shao , Y ., 2022.Mater . Horiz.9(1),383-392. V agha s iya , J .V ., Mayorga -Mart i nez, C.C ., Vys k oc i l , J ., Pumera , M., 2022. Biose n s. Bioelect r on . 205,114092. Wang, L., Wa n g, L., Z h a n g, Y., P an , J., Li , S., Sun , X., Z h ang, B., Pen g , H., 2018. Ad v .Fun c t . Ma ter. 28 (42),1804456. Wang, P., Men g, Z., Wang, X ., Zhao , Z., W a n g, Y., Qu an , F., T i an , W ., Yang , C ., Zh an g, K.,X i a , Y ., 2022. J . M a t er . Ch e m. 10 (16), 8948-8957. Wei, X., Z h u, M ., L i , J., Li u , L ., Y u , J., L i , z., D ing, B., 2021. N ano E ne rg y 85, 106031.W u , H., Xu , L., Wang, Y., Zh an g,T ., Z ha n g, H ., Bowen , C.R., Wang , Z .L ., Ya n g, Y., 2020.ACS E n e rgy Le tt . 5 (12), 3708-3717. Xiao, G ., J u , J ., L u, H ., S h i , x ., Wan g , X ., Wang, W., Xia , Q., Z h ou , G ., Sun , W., L i , C .M.,Q i ao, Y., Lu, Z ., 2022. Adv. Sci . 9 (7), 2103822. Xu , J ., F ang , Y ., C h en , J ., 2021. Bio sen sors 11 (8),245,2021. Xue, L ., Fan , W ., Yu , Y ., D on g, K., L i u , C ., S u n, Y ., Zhang , C., C h en , W., L e i , R., Ron g, K .,Wa n g , Q ., 2021. A d v. F i b e r M a ter . 3 (4), 239-250. Y a n g, Y., We i, X ., Zhang , N ., Z h e n g , J., Ch e n, X., Wen , Q., L uo , X., Lee, C .-Y., Li u , X., Zh an g, X ., C he n , J ., Tao , C ., Z h a n g , W., F a n , X., 2021. N a t . Co m m un . 12(1),4876. Y i n, L ., Kim, K.N ., L v, J ., Teh r an i , F ., Li n , M ., L i n , Z., Mo on , J .-M., Ma, J ., Yu , J ., X u, S.,Wa n g,J ., 2021a. Na t . Co m m u n. 12 (1),1542. Yin, L., Mo o n, J.-M., Sem pi ona t to , J .R., L i n, M., Ca o ,M., Tri fo nov, A., Z h ang, F ., Lou, Z.,Je on g, J .-M ., Le e , S.-J ., Xu , S., Wan g , J ., 2021b. Jou l e 5 (7),1888-1904. Y u, Y ., Pan , D ., Z h a o , L ., Hu ang , S ., Li n, P., Wa n g , Z., J i a, Y ., Wa n g, H ., Wan g, L ., 2022.Adv. Fi be r Mater. 4 (5), 1246-1255. Zh an g, J ., L i u , J ., Su , H., Su n , F ., Lu , Z., Su , A., 2021. Sen s o r s Actuat. B-C h em. 341,130046. Z hao , X ., Z h o u , Y., X u, J ., Ch e n, G ., F a n g, Y ., Ta t , T ., X i ao , X ., S o ng, Y ., Li, S., C h en , J .,2021. Na t. C ommu n. 12 (1),6755.

确定

还剩9页未读,是否继续阅读?

雷迪美特中国有限公司为您提供《【PalmSens4电化学应用】西南大学鲁志松教授、乔琰副教授团队Biosensor. Bioelectrn.:可编织与自充电的汗液激发纱线电容器》,该方案主要用于其他中物理指标检测,参考标准--,《【PalmSens4电化学应用】西南大学鲁志松教授、乔琰副教授团队Biosensor. Bioelectrn.:可编织与自充电的汗液激发纱线电容器》用到的仪器有PalmSens4便携式电化学工作站

该厂商其他方案

更多