方案详情

文

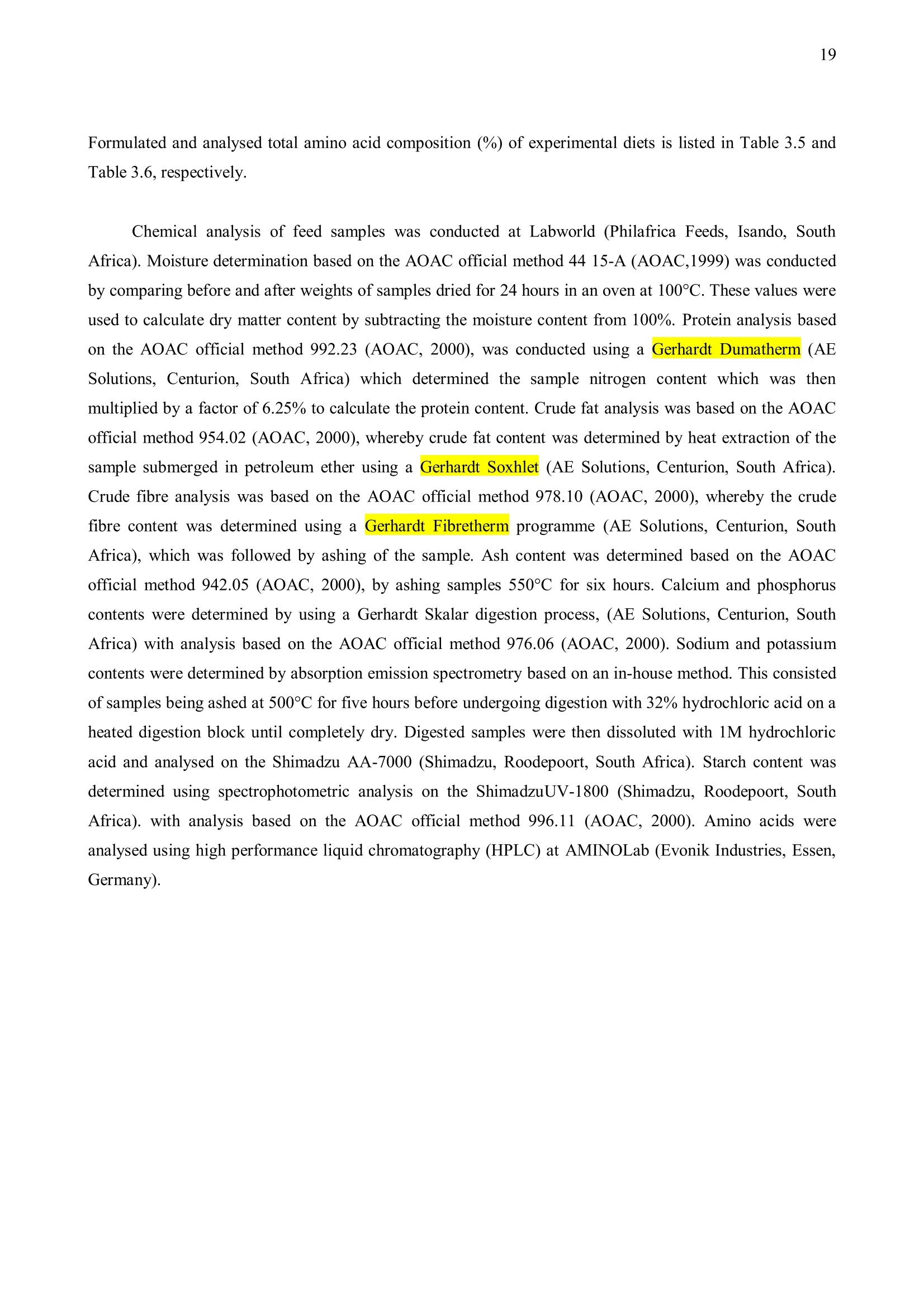

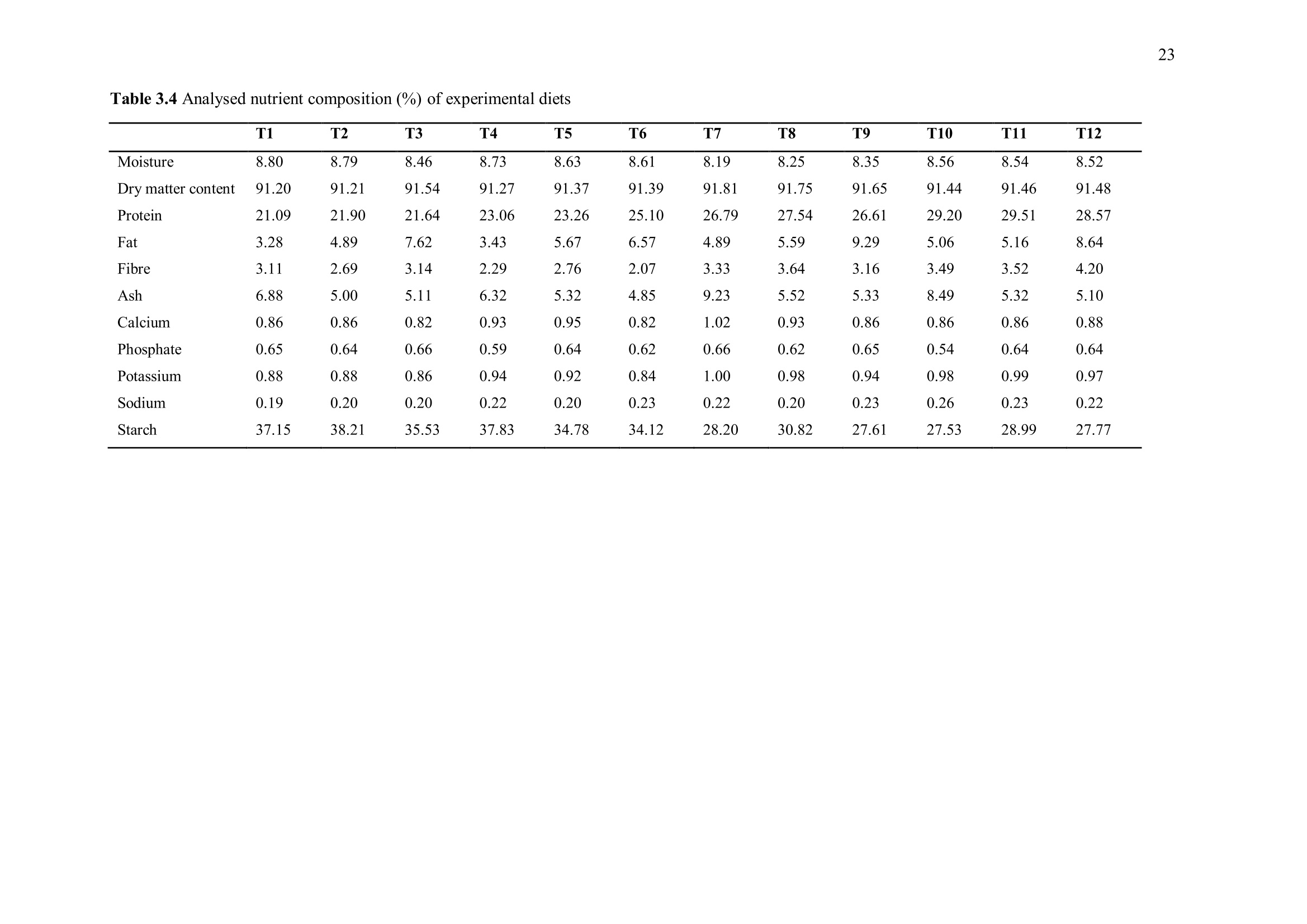

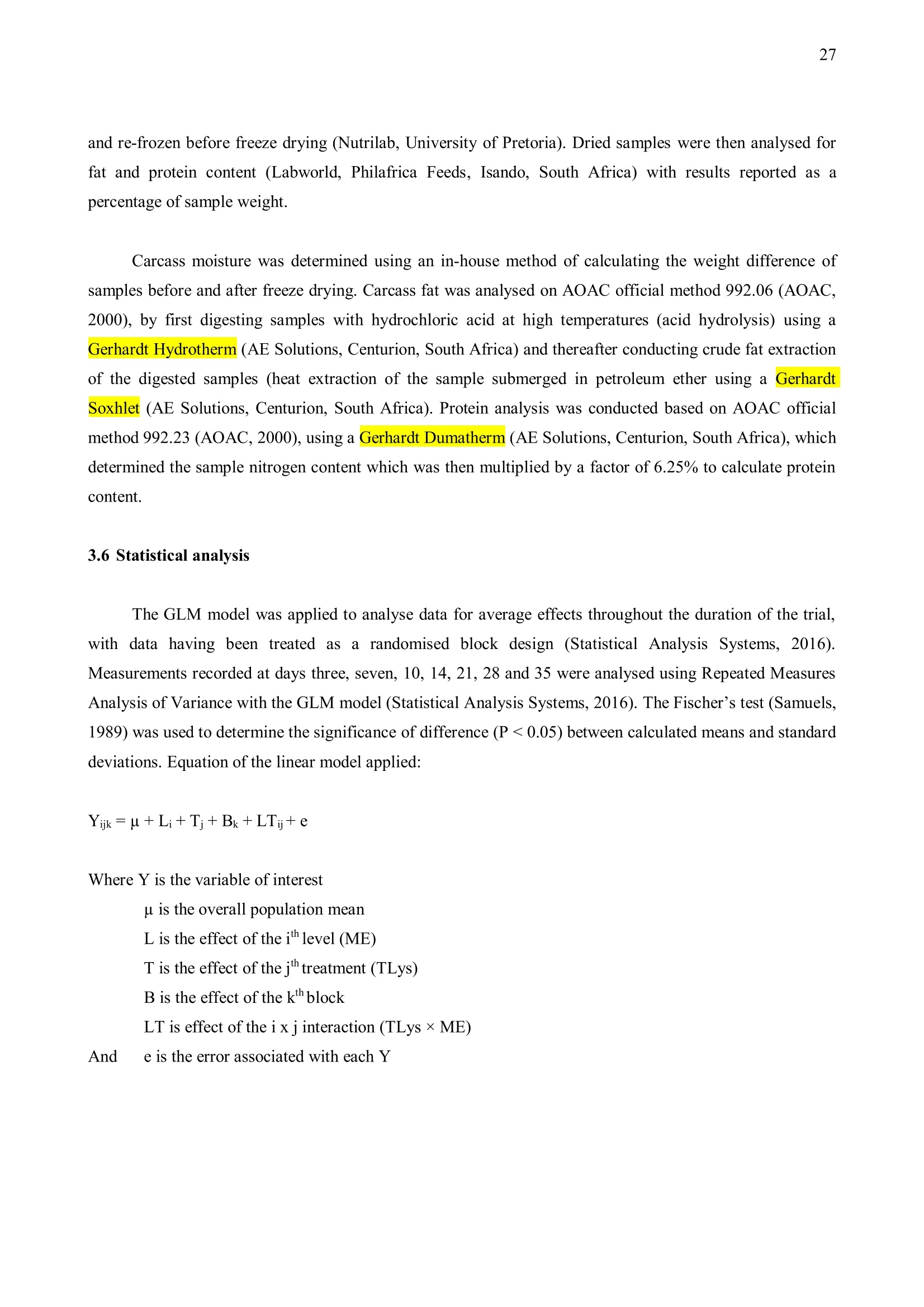

使用格哈特公司杜马森Dumatherm N pro杜马斯定氮仪测定饲料、肉鸡蛋白质含量,使用格哈特公司海卓森Hydrotherm全自动超级酸水解结合索克森Soxtherm全自动快速索氏提取仪测定饲料、肉鸡总脂肪含量,使用格哈特公司费博森Fibretherm全自动纤维测定仪测定饲料粗纤维含量。

方案详情