方案详情

文

采用美国Artium公司的无光纤式集成化DPSSL半导体泵浦的固体激光器构成的相位多普勒干涉仪测量系统,测量高速空气流中两个空气雾化喷嘴的喷雾中的液滴粒径和速度,并研究了其相互作用规律。

方案详情

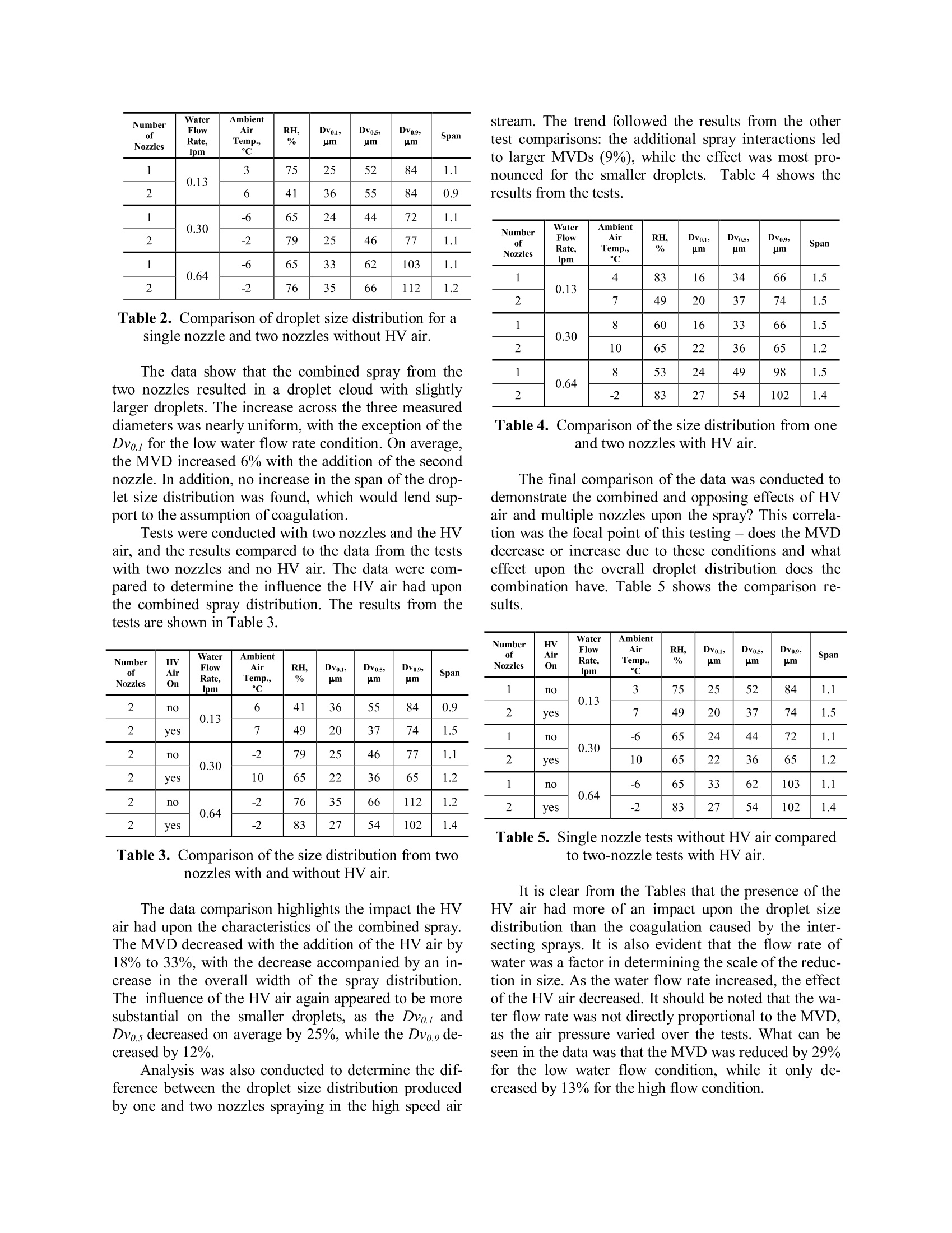

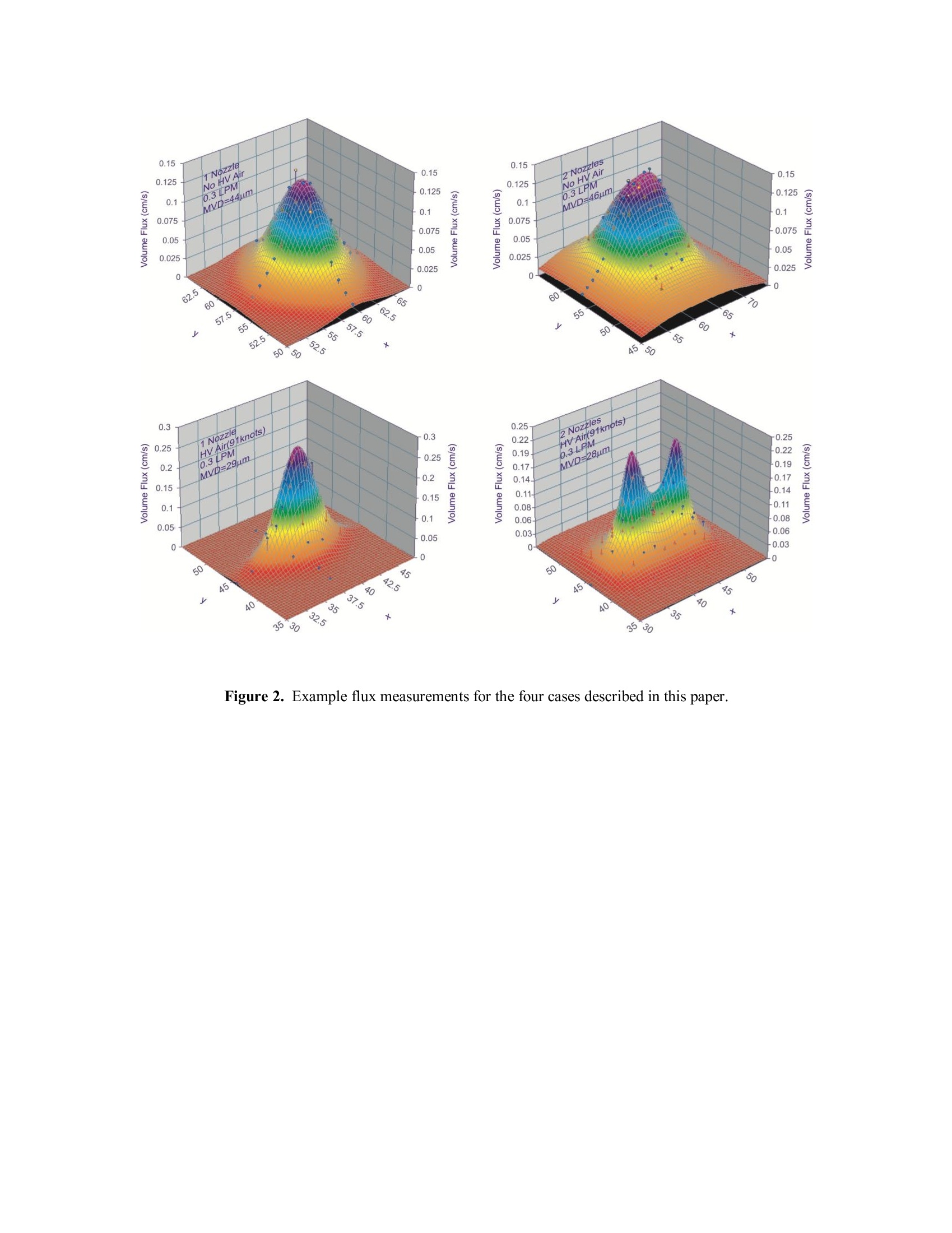

ILASS Americas, 25" Annual Conference on Liquid Atomization and Spray Systems, Pittsburgh, PA, May 2013 Spray Interaction of Two Air Atomizing Nozzles in High Velocity Air Richard J. Byers, Timothy E. Lane, and Brian R. Collett Battelle MemorialInstitute 505 King Avenue Columbus, OH 43201 USA Abstract Air atomizing nozzles are used to produce a polydisperse distribution of droplets. When droplets exiting a nozzlecollide with droplets from other sprays, they may either coagulate and grow in size or potentially undergo furtheratomization and reduce in size. The size and relative motion of the individual droplets will have a significant effecton the process. In addition, when the droplets are subjected to external velocities that result in turbulent flow, shearcoDaaggulation can have a substantial impact on the combined spray distribution, especially for larger droplets. For ourcurrent study, we are developing an array of air atomizing nozzles to produce airborne icing clouds, with medianvolume diameters (MVD) in the 20 to 50 pum range. The nozzles are spaced approximately 10 centimeters apart hor-izontally and subject to wind speeds ranging from 50 to 140 knots. The shearing effect created by the relative windspeed may reduce the initial droplet size by secondary atomization, while the droplet interactions may lead to coagu-lation. These competing phenomena were evaluated using an Artium Phase Doppler Interferometer (PDI) to charac-terize the size distribution of droplets undergoing simultaneous shear and coagulation. The data show that the airflowing past the nozzles had a significant effect upon the droplet size for individual nozzle sprays, reducing theMVD by 27% on average. The data also showed the combined spray from two nozzles had a 9% larger MVD thanthat from a single nozzle; however, with the reduction in droplet size due to the high velocity (HV) air flow, theoverall MVD was still reduced (24% on average). This paper further describes the test results for one and two noz-zles generating droplets in still air and with HV air flow, and how the droplet size and water flow rate appeared toinfluence the evaporation /coagulation ratio. ( C o r responding author: b yersr@battelle.org ) Introduction In-flight aircraft icing has contributed to multipleaviation accidents in recent years. The buildup of ice onaircraft surfaces can lead to reduced lift, increased drag,decreased maneuverability, and sensor malfunction,among other concernsS[1]. Icing clouds consist ofsurpercooled water droplets that remain in the liquidstate despite temperatures significantly below freezing.Upon impact with a surface, the droplets may instantlyfreeze or remain liquid and spread before turning to ice[1,2]. The characteristics of the ice largely depend uponthe environmental conditions and droplet size [3]. Dueto the potential hazards of ice formation on aircraft sur-faces, the Federal Aviation Administration (FAA) re-quires aircraft to be icing-certified in order to be able tooperate in icing conditions. The conditions are specifiedin Federal Aviation Regulations (FAR) Appendix C toPart 29 - Icing Certification, which describes continu-ous and intermittent maximum icing [4]. The defini-tions are based upon curves of liquid water content(LWC) and Mean Effective Diameter of the dropletsconstituting the cloud at different air temperatures. Thedroplet diameter is equivalent to the Median VolumeDiameter (MVD) for the supercooled water droplets. Inorder to be allowed to fly through an icing cloud with-out immediately exiting the cloud, the aircraft must becertified. In order to test aircraft anti-icing mechanisms inflight, a spray array system was developed and installedon a CH-47 helicopter. The Helicopter Icing Spray Sys-tem (HISS) has been used for four decades to certifyfixed- and rotary-wing aircraft [5]. The airborne spraytanker was developed for the U.S. Army in 1973 and isowned and operated by the Redstone Test Center’sAviation Flight Test Directorate (RTC-AFTD), Red-stone Arsenal, Alabama. The current HISS is capable ofproducing 11 m by 2.4 m icing clouds at altitudes up to3,000 m above ground level. In order to expand thetesting envelop in terms of cloud size, the Central Testand Evaluation Investment Program (CTEIP), throughthe U.S. Army Program Executive Office for Simula-tion, Training, and Instrumentation (PEO STRI), hasrequested an improved test system for performing in-flight icing testing for low-speed air vehicles [6]. Therequirements for the Objective Helicopter Icing SpraySystem (OHISS) call for an expanded cloud size (pro-files of 18.3 m by 2.4 m and 5.5 m by 6.1 m) that meetsthe cloud specifications in accordance with FAA Advi-sory Circular 29-2C, Figures 29.877-3 and 29.877-4[7]. Based on these specifications, the key performanceparameters call for droplets ranging from 20 to 50 umMVD and LWC levels of 0.7 to 1.5 g/m’[8]. Experimental Setup Multiple nozzles were previously tested to deter-mine the effectiveness of covering the range of droplet sizes and water flow rates. Two nozzles from SprayingSystems Company were selected to achieve the entirerange. In order to reduce the complexity of the OHISS,one nozzle will be used for a large majority of the test-ing - SS3 (PF60100/PA1401110), and that nozzle is thefocus of this paper. The SS3 nozzle was studied exten-sively in the laboratory, using the PDI to measure thedroplet size distribution of a single nozzle over a rangeof input conditions. The actual OHISS spray boom, a17.8 by 7.1 cm ellipse, will contain hundreds of noz-zles, with approximately 10 horizontal centimeters be-tween nozzle tips. The characteristics of the resultingspray are the focus of this paper. Droplet collisions may lead to secondary atomiza-tion or coagulation, with droplet size and relative mo-tion having a substantial influence on the resulting sizedistribution [9]. When the sprays are entrained in highspeed air flow, shear coagulation and droplet evapora-tion can affect the spray distribution [9,10]. For eventu-al OHISS deployment, the sprays will be subjected towind speeds ranging from 50 to 140 knots at tempera-tures between 0 and -24℃. Therefore, individual spraynozzle performance in a laboratory setting may not beindicative of the final spray characteristic. In order to evaluate the droplet interaction, Battelleused an Artium PDI to characterize the size distributionof droplets from single and dual nozzles at air speedsfrom 40 to 100 knots under ambient, uncontrolled envi-ronmental conditions [11]. A discussion of the PDI canbe found in the accompanying paper“Performance ofan Air-Assist Nozzle Using Heated Air”[12]. The boomsection and nozzles were mounted in a 38 cm duct at-tached to the outlet of a high speed blower. Figure 1shows the nozzles during a test and the location of thePDI. Figure 1. Dual spray nozzles under test with the PDI. The facility used for these tests was Battelle’s Am-bient Breeze Tunnel (ABT), which is a large, open-ended structure. This facility was used to shield theinstruments from the elements while also allowing test-ing to occur in cold weather. The test temperature rangewas -7℃ to 12℃, while the relative humidity rangedfrom 37% to 91%. An array of water flow rates wasused at varying air pressures to measure the droplet sizedistribution produced from both the single and dual nozzle setup with and without the high speed air. ThePDI data show the distribution of the droplets and howthe interaction of the sprays affected the overall spraycharacteristics. Tests were conducted at several flow rate and pres-sure settings in order to meet specific criteria for drop-let size and concentration at three air speeds. For eachtest, the droplet size distribution was measured and thetest conditions recorded. The droplet size data is pre-sented in terms of three cumulative sizes, denoted Dvo.i,Dvo.5 (MVD), and Dvo.9. These equate to the volume-based droplet diameter where 10, 50, and 90% of thedroplets are less than or equal to this size, respectively.A relative span value was also calculated based on thisdata to provide a point of comparison for the width ofthe size distribution. The span was calculated as [(Dvo.-Dvo.i)/ Dvo.s]. Because tests were performed at ambient condi-tions, the temperature and relative humidity variedthroughout testing. These variations were addressed,but not specifically taken into account in the data analy-sis. While a total of 60 tests were conducted with theSS3 nozzle, the data set is not sufficiently broad to cal-culate the effects temperature and relative humidity hadupon the spray characteristics. Results The focus of this paper is on the combined spraycharacteristics. In order to illustrate the behavior of thecombined spray, nozzles were tested with and withoutthe high speed blower operating, and individual nozzleswere tested as well. For the test results presented here,the water flow rate per nozzle ranged from approxi-mately 0.13 to 0.64 liters per minute (lpm). While threeair speeds were used during testing, there was no dis-cernible effect of increasing air speed upon the droplets.Droplet sizes from tests conducted at the low air speedsetting (approximately 45 knots) were not statisticallydifferent from those conducted at the high air speedsetting (approximately 100 knots). Figure 2 at the endof this paper shows example flux measurements fromthe four main test settings. Again, please refer to theaccompanying paper, “Performance of an Air-AssistNozzle Using Heated Air”, for a complete description ofhow the Dvo.1,Dvo.5, and Dvo.9 values were calculated. The nozzle data were analyzed by comparing theMVD in the following manner: one nozzle with andwithout HV air, two nozzles with and without HV air,one nozzle to two nozzles with HV air, and one nozzleto two nozzles without HV air. The data set was intend-ed to give a full representation of the processes affect-ing the spray characteristics. It should be noted that thedata in subsequent tables show that the air temperatureand relative humidity were variable throughout thecourse of these tests, but no clear trend in the dropletdistribution was seen. Also of note is that the results for the test data where the HV blower was operational wereaveraged over three tests, while the data for the testswhere the HV blower was not operating were from asingle test. The results from the single nozzle tests with andwithout the high speed blower are shown in Table 1.The data in the table include the environmental testconditions, the flow rate of water, and the resultingdroplet size characteristics. Number of Nozzles HVAiron WaterFlowRate.ipm AmbientAirTemp.,°C RH.% Dvo.1,um DVo.5,um DVo.9,m Span 1 no 0.13 3 75 25 52 84 1.1 1 yes 4 83 16 34 66 1.5 1 no 0.30 -6 65 24 44 72 1.1 1 yes 8 60 16 33 66 1.5 1 no 0.64 -6 65 33 62 103 1.1 1 yes 8 53 24 49 98 1.5 Table 1. Single nozzle tests with and without HV air. The reduction in MVD due to the addition of theair is evident from the data. The HV air reduced theMVD by 21 to 35%, with the largest decrease seen atthe lowest water flow rate. What can also be seen fromthe data is that the span results show that the HV airbroadens the distribution of the spray while decreasingthe droplet size. The air flow has less of an effect on thelarger droplets (shown by the Dvo. data), and the mostinfluence on the smallest droplets (Dvo.i). This wouldtend to imply that the HV air increases evaporation,thus reducing the overall droplet size, as opposed toenhancing droplet shear. If shear were the predominantfactor, the larger droplets would be most affected, withthe smaller droplets showing the least amount of im-pact. To assess the impact of multiple nozzle sprays onthe combined droplet distribution, the data collected fora single nozzle operating without the HV air was com-pared to the droplet data for two nozzles without HVair. The tests were conducted to provide a baseline forcomparison with the tests with the HV air. Table 2shows the results from the six tests. NumberofNozzles WaterFlowRate.ipm AmbientAirTemp.,°C RH.% Dvo.1,um DVo5,pm DV0.9,m Span 1 0.13 3 75 25 52 84 1.1 2 6 41 36 55 84 0.9 1 0.30 -6 65 24 44 72 1.1 2 -2 79 25 46 77 1.1 1 0.64 -6 65 33 62 103 1.1 2 -2 76 35 66 112 1.2 Table 2. Comparison of droplet size distribution for asingle nozzle and two nozzles without HV air. The data show that the combined spray from thetwo nozzles resulted in a droplet cloud with slightlylarger droplets. The increase across the three measureddiameters was nearly uniform, with the exception of theDvo.1 for the low water flow rate condition. On average,the MVD increased 6% with the addition of the secondnozzle. In addition, no increase in the span ofthe drop-let size distribution was found, which would lend sup-port to the assumption of coagulation. Tests were conducted with two nozzles and the HVair, and the results compared to the data from the testswith two nozzles and no HV air. The data were com-pared to determine the influence the HV air had uponthe combined spray distribution. The results from thetests are shown in Table 3. NumberofNozzles HVAirOn WaterFlowRate,Ipm AmbientAirTemp.,°C RH,% DVo.1,m DV0.5,m Dv0.9,pm Span 2 no 0.13 6 41 36 55 84 0.9 2 yes 7 49 20 37 74 1.5 2 no 0.30 -2 79 25 46 77 1.1 2 yes 10 65 22 36 65 1.2 2 no 0.64 -2 76 35 66 112 1.2 2 yes -2 83 27 54 102 1.4 Table 3. Comparison of the size distribution from twonozzles with and without HV air. The data comparison highlights the impact the HVair had upon the characteristics of the combined spray.The MVD decreased with the addition of the HV air by18% to 33%, with the decrease accompanied by an in-crease in the overall width of the spray distribution.The influence of the HV air again appeared to be moresubstantial on the smaller droplets, as the Dvo. andDvo.5 decreased on average by 25%, while the Dv0. de-creased by 12%. Analysis was also conducted to determine the dif-ference between the droplet size distribution producedby one and two nozzles spraying in the high speed air stream. The trend followed the results from the othertest comparisons: the additional spray interactions ledto larger MVDs (9%), while the effect was most pro-nounced for the smaller droplets. Table 4 shows theresults from the tests. NumberofNozzles WaterFlowRate,Ipm AmbientAirTemp.,°C RH.% Dvo.1,pm Dvo.5,pm DV09,m Span 1 0.13 4 83 16 34 66 1.5 2 7 49 20 37 74 1.5 1 0.30 8 60 16 33 66 1.5 2 10 65 22 36 65 1.2 1 0.64 8 53 24 49 98 1.5 2 -2 83 27 54 102 1.4 Table 4. Comparison of the size distribution from oneand two nozzles with HV air. The final comparison of the data was conducted todemonstrate the combined and opposing effects of HVair and multiple nozzles upon the spray? This correla-tion was the focal point of this testing - does the MVDdecrease or increase due to these conditions and whateffect upon the overall droplet distribution does thecombination have. Table 5 shows the comparison re-sults. Discussion The main focus of this testing was to determine theeffects high velocity air and non-laboratory test condi-tions have upon the selected icing cloud nozzle sprays.It was predicted that there would be several competingphenomena occurring coagulation, secondarybreakup, shear, and evaporation. The variability of theambient conditions did not allow for an estimate of theeffect of temperature and relative humidity upon theresults; however, the influence HV air had upon thenozzle spray characteristics was evident. Tests with the single nozzle created a baseline fromwhich the variables of air flow and number of nozzlescould be assessed. The addition of the HV air signifi-cantly reduced the MVD and simultaneously increasedthe width of the size distribution. This preferential re-duction in size can be attributed to evaporation inducedby the air flow. Since the larger droplets were not great-ly reduced in size, shear created by the turbulent airflow did not appear to have an impact on the spray. Hadshear been evident, it would be expected that the largerdroplets would have undergone the largest reduction insize. Another aspect of this testing showed that the actu-al wind speed did not have a significant effect upon thedroplet size distribution. While this data is not present-ed here, no clear pattern emerged with respect to MVDor span in relation to the wind speed. Tests with two nozzles spaced approximately 10cm apart were conducted without the HV wind as well.These tests showed that the interaction of the twosprays increased the overall median droplet size, but byless than 6%.The width of the distribution was not af-fected by the interaction of the two sprays. It is likelythat the momentum for each spray was reduced signifi-cantly prior to the spray plumes colliding such that theforce of the droplet impactions was not sufficient tocause the droplets to coalesce or cause secondarybreakup on a large scale. The key aspect of these tests was to determine howthe interactions between nozzles in the presence of ahigh velocity air alter the spray characteristics com-pared to a single nozzle in still air. This information isneeded to be able to predict the icing cloud propertiesand to understand how changes in test conditions canaffect the cloud quality. The results showed that thecompeting effects of bulk air flow and coagulation arenot completely balanced, with enhanced evaporationdue to the air flow outweighing droplet coagulation. A20% reduction in the MVD was observed when com-paring the sprays from two nozzles with HV air to asingle nozzle without HV air. Also, the reduction indroplet size is more pronounced with lower flow ratesof water through the nozzles and for smaller droplets.Table 6 shows a summary of the findings for each pointof comparison. Test Condition Effect 1 nozzle withand without HVair 27% reduction in MVD due to airflow; effect diminished with higherwater flow rate and larger droplets 1nozzle vs.2nozzles 6% increase in MVD due to dualspray interaction; no difference dueto water flow rate or droplet size 1 nozzle vs. 2nozzles withHV air 9% increase in MVD due to dualspray interaction; no difference dueto water flow rate or droplet size 2 nozzles withand without HVair 24% reduction in MVD due to airflow; effect diminished with higherwater flow rate and larger droplets 1 nozzle with-out HV air vs. 2nozzles withHV air 20% reduction in MVD due to airflow; effect diminished with higherwater flow rate and larger droplets Table 6. Summary of effects observed. The results show evaporation due to air flow wasthe key driver in the modified droplet size distribution.This effect was lessened as the droplets increased insize, as would be expected. In addition, the amount ofwater flowing through the nozzles also decreased theeffect of evaporation. This can likely be attributed tothe higher vapor concentration surrounding the individ-ual droplets, thus suppressing the evaporation rate. The effects of coagulation were demonstrated inthe increase in droplet size with the addition of the se-cond nozzle spray; however, the effect only increasedthe MVD 6% to 9%. Also, secondary breakup of drop-lets due to high velocity impaction or shear was notseen in the data. All the data do show that at the impac-tion point of the nozzle sprays, the increase in dropletsize due to coalescence was less significant than windinduced evaporation. Acknowledgements The authors would like to thank Darrell Wright andLuis Pineiro of PEOSTRI for encouraging and support-ing this work. References 1. Steuernagle,J., Roy, K., and Wright, D., eds, Air-craft Owners and Pilots Association Air SafetyFoundation, Safety Advisor: Weather No.1, Freder-ick, Maryland,2008. 2. Hanks,K.W.,“Atmospheric Conditions Conduciveto Aircraft Icing,”Auburn University Research Pa-per, 2000. 4. Code of Federal Regulations, Title 14, Aeronauticsand Space, Federal Aviation Regulation (FAR) Part29, Airworthiness Standards: Transport CategoryRotorcraft, Appendix C, current edition. 5. Belte, D., “Helicopter Icing Spray System (HISS)Nozzle Improvement Evaluation,”United StatesArmy Aviation Engineering Flight Activity FinalReport 79-02-02,1981. 6. Project Manager for Instrumentation, Targets, &Threat Simulators,“Objective Helicopter IcingSpray System (OHISS),” Press Release updated No-vember 2012. 7. Federal Aviation Administration (FAA) AdvisoryCircular 29-2C,“Certification of Transport Catego-ry Rotorcraft,”1999. 8. Pineiro, L.A., and Vuong, F.R.,“Performance Spec-ification for Objective Helicopter Icing Spray Sys-tem (OHISS) Cloud Generation System,”PRF-PT-00511,W900KK-10-R-0016,28 March 2010. 9. Seinfeld, J. H., and Pandis, S. N., AtmosphericChemistry and Physics: From Air Pollution to Cli-mate Change, John Wiley & Sons, Inc., New York,1998, p. 656-664. 10. Hinds, W. C., Aerosol Technology: Properties, Be-havior, and Measurement of Airborne Particles,John Wiley & Sons, Inc., New York, 1999, p. 240-246;265-271. 11.Artium Technologies, Inc., PDI-200 MD User Man-ual, 2012, Sunnyvale, CA. 12.Lane, T. E., Collett, B. R., Byers,R. J.,“Perfor-mance of an Air-Assist Nozzle Using Heated Air,”25th Annual Conference on Liquid Atomization andSpray Systems, Pittsburgh, PA, May 2013. 62.5 57.5 52.5 979 929 979 Volume Flux (cm/s) ON MVD=29um 品 8Volume Flux (cm/s) s O Volume Flux (cm/s)0B831 14 0.3LPA 5 MVD=28umL EL9 t79 06 品 T000.O.1.14Volume Flux (cm/s) 8 Air atomizing nozzles are used to produce a polydisperse distribution of droplets. When droplets exiting a nozzle collide with droplets from other sprays, they may either coagulate and grow in size or potentially undergo further atomization and reduce in size. The size and relative motion of the individual droplets will have a significant effect on the process. In addition, when the droplets are subjected to external velocities that result in turbulent flow, shear coagulation can have a substantial impact on the combined spray distribution, especially for larger droplets. For our current study, we are developing an array of air atomizing nozzles to produce airborne icing clouds, with median volume diameters (MVD) in the 20 to 50 m range. The nozzles are spaced approximately 10 centimeters apart hor-izontally and subject to wind speeds ranging from 50 to 140 knots. The shearing effect created by the relative wind speed may reduce the initial droplet size by secondary atomization, while the droplet interactions may lead to coagu-lation. These competing phenomena were evaluated using an Artium Phase Doppler Interferometer (PDI) to charac-terize the size distribution of droplets undergoing simultaneous shear and coagulation. The data show that the air flowing past the nozzles had a significant effect upon the droplet size for individual nozzle sprays, reducing the MVD by 27% on average. The data also showed the combined spray from two nozzles had a 9% larger MVD than that from a single nozzle; however, with the reduction in droplet size due to the high velocity (HV) air flow, the overall MVD was still reduced (24% on average). This paper further describes the test results for one and two noz-zles generating droplets in still air and with HV air flow, and how the droplet size and water flow rate appeared to influence the evaporation /coagulation ratio.

确定

还剩5页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《空气雾化喷嘴中喷雾液滴粒径和速度,喷雾相互作用检测方案(激光干涉仪)》,该方案主要用于其他中喷雾液滴粒径和速度,喷雾相互作用检测,参考标准--,《空气雾化喷嘴中喷雾液滴粒径和速度,喷雾相互作用检测方案(激光干涉仪)》用到的仪器有激光相位多普勒干涉仪LDV,PDI,PDPA,PDA

相关方案

更多

该厂商其他方案

更多