金属材料中微观结构检测方案(其它元素分析仪)

Abstract. This study investigates the changes in radial micro-texture via Kearn’s f-factors during single cold pilger reduction

of a titanium Ti-3-2.5 alloy as a result of strain path changes from tooling modifications. EBSD results confirm that the

texture intensity as well as the radial f-factors can be increased by modifications of pilgering tooling. In addition a switch

between the secondary prism planes which lie normal to the pilger direction in the starting tube to primary prism planes

after pilgering has been observed.

Material and Experimental

The tubes investigated were made from Ti alloy 3Al 2.5V, they were manufactured via hot extrusion and then cold pilgered.

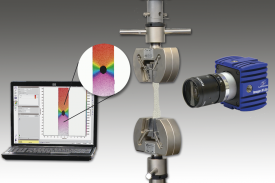

The cold pilger process configuration is schematically shown in Figure 1. Two strain paths, shown in the ‘Q‘ factor chart in

Figure 2, were used in the manufactiure: texture minimised and texture maximised. They were annealed at 750oC before

being cold pilgered and for this investigation they were stress relieved at 530oC for 2 hours prior to EBSD examination.

Specimens were extracted from two regions either side of the reduced tube as shown in the schematic Figure 2, mounted

in conductive Bakelite and polished mechanically for EBSD examination. The final polish was carried out using vibratory

polishes using a mixture of 5:2 colloidal silica, hydrogen peroxide mixture. EBSD examination was conducted using a

FEGSEM and OI EBSD Nordlys detector and AZtec Software.

检测样品:

其他

检测项:

理化分析

牛津仪器科技(上海)有限公司

查看联系电话

前往展位

化合物半导体核壳结构纳米金属线中低加速电压SEM/STEM观察/EDX分析检测方案(扫描电镜)

半导体纳米金属线,因其物理特性可控,所以未来有望应用于光学器件上。尤其是异相聚合机构或者核壳结构的材料,富有多重物理特性,应用范围也会变得更广泛。图1是化合物半导体核壳结构纳米金属线的SE/STEM观察结果。图1(a)是二次电子图像显示了纳米金属线的表面形貌。图1(b)(c)的BF-STEM/DF-STEM图像,可以清楚观察到纳米金属先端的内部构造,可以确认核,内壳层和外壳层的三层结构。

图2是化合物半导体核壳结构纳米金属线的EDX面分布。核壳层和外壳层检测到Ga和As,内壳层检测到Al和As,能够清楚地分离出三层的结构的各种成分分布。SU9000与大立体检测角的X-MaxN 100TLE相结合,可实现超高空间分辨率的EDX面分布。

检测样品:

其他

检测项:

理化分析

日立科学仪器(北京)有限公司

查看联系电话

前往展位

金属粉末中表面形状检测方案(扫描电镜)

3D打印(3 Dimensional Printing)又名增材制造(material additive manufacturing),是一种使任何形状的三维固体物品通过数字模型得以快速实现的过程。3D打印的实质是通过计算机辅助设计软件,将某种特定的加工样式进行一系列的数字切片编辑,从而生成一个数字化的模型文件,然后按照模型图的尺寸以某些特定的添加剂作为粘合材料,运用特定的成型设备即3D打印机,用粉末态、液态、丝状等的固体金属粉或可塑性高的物质进行分层加工、叠加成型使原料将这些薄型层面逐层熔融增加,从而最终“打印”出真实而立体的固态物体。通俗一点就是类似于挤牙膏,只不过挤出来的牙膏是按照一定程序规则堆叠成一个特定的形状结构。3D 打印技术被称为“具有工业革命意义的制造技术”,是制造业领域正在迅速发展的一项新兴技术,已成为现代模型、模具和零部件制造的有效手段,在航空航天、生物医学、材料科学等领域得到了一定应用。

检测样品:

其他

检测项:

理化分析

复纳科学仪器(上海)有限公司

查看联系电话

前往展位

仪器信息网行业应用栏目为您提供5篇其他检测方案,可分别用于,参考标准主要有等