方案详情

文

动态成像颗粒分析系统具有行业领先成像质量和自动识别统计的软件,是检测,表征和定量各种油气行业应用的有效工具。

• 每分钟分析数以万计的颗粒 – 能够快速统计相关结果

• 能够对所成像的每个颗粒进行40多种物理参数测量

• 能够准确地获得颗1 µm到600 µm颗粒的计数和形态

• 高质量的图片可以将实时数据核实可视化 – 非凡的图像质量可以准备地进行基于图像的颗粒测量。

• 使用自动化的,可建模的,基于自动识别统计软件,可将不同的颗粒进行分门别类,从而节省时间。

方案详情

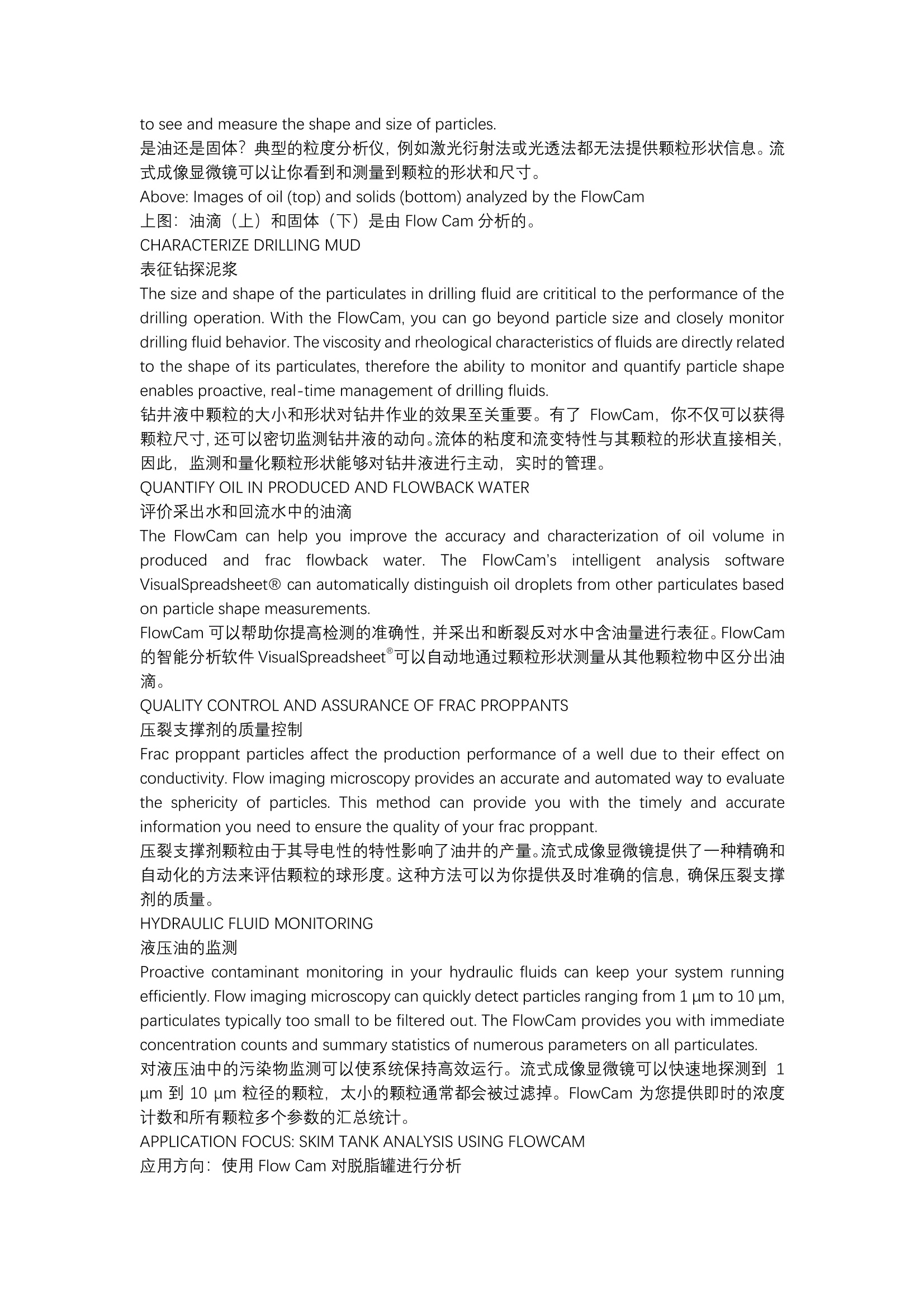

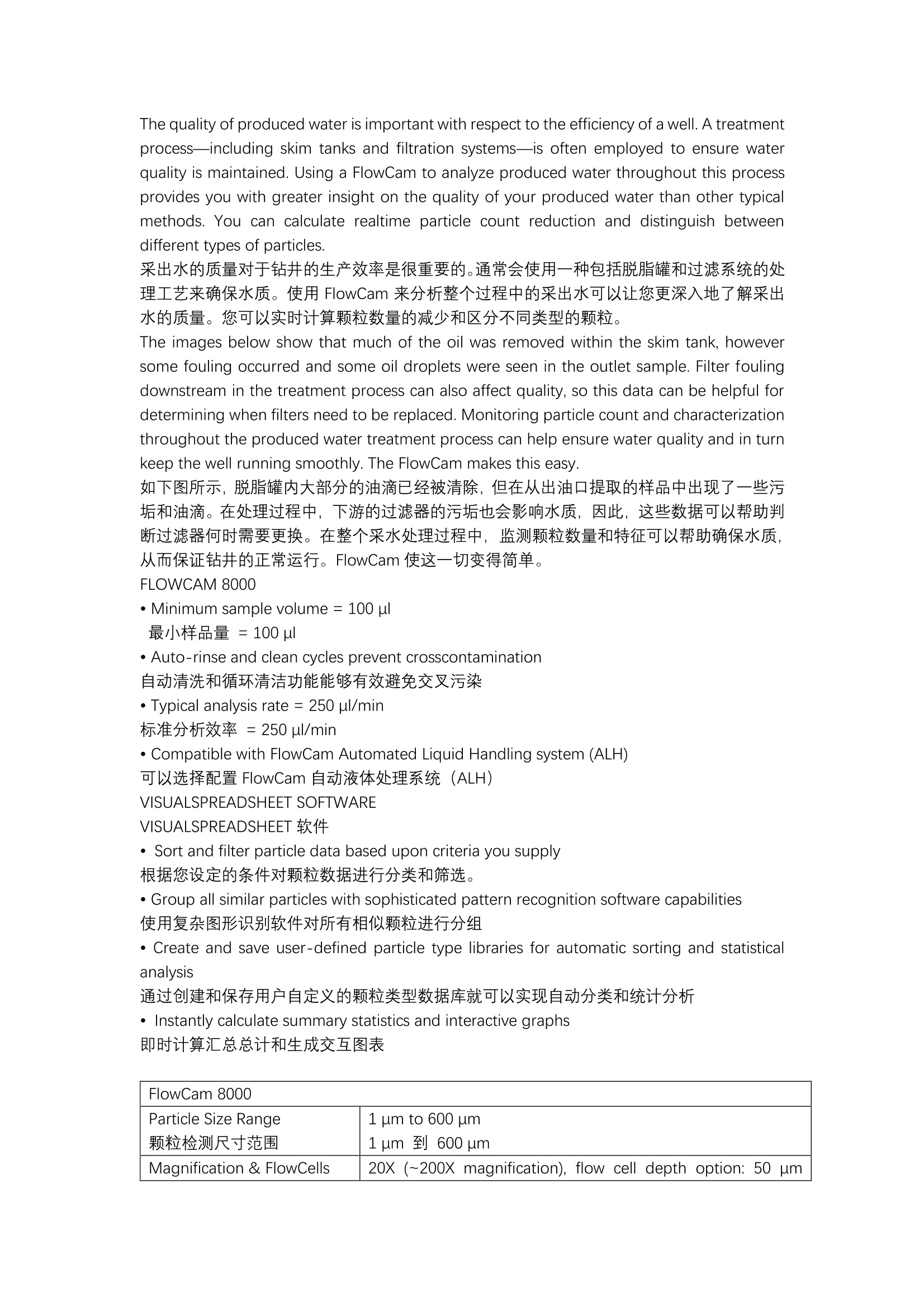

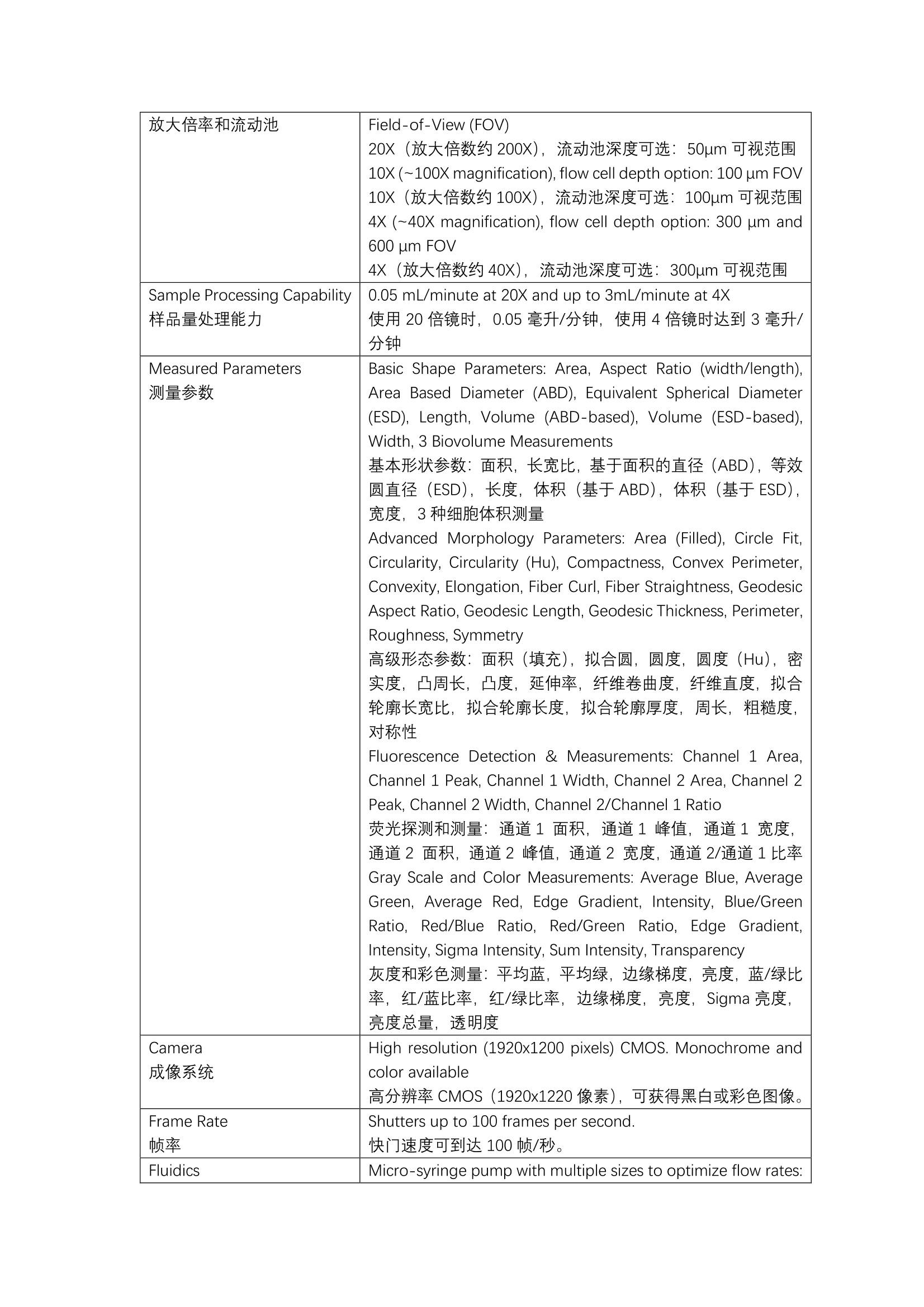

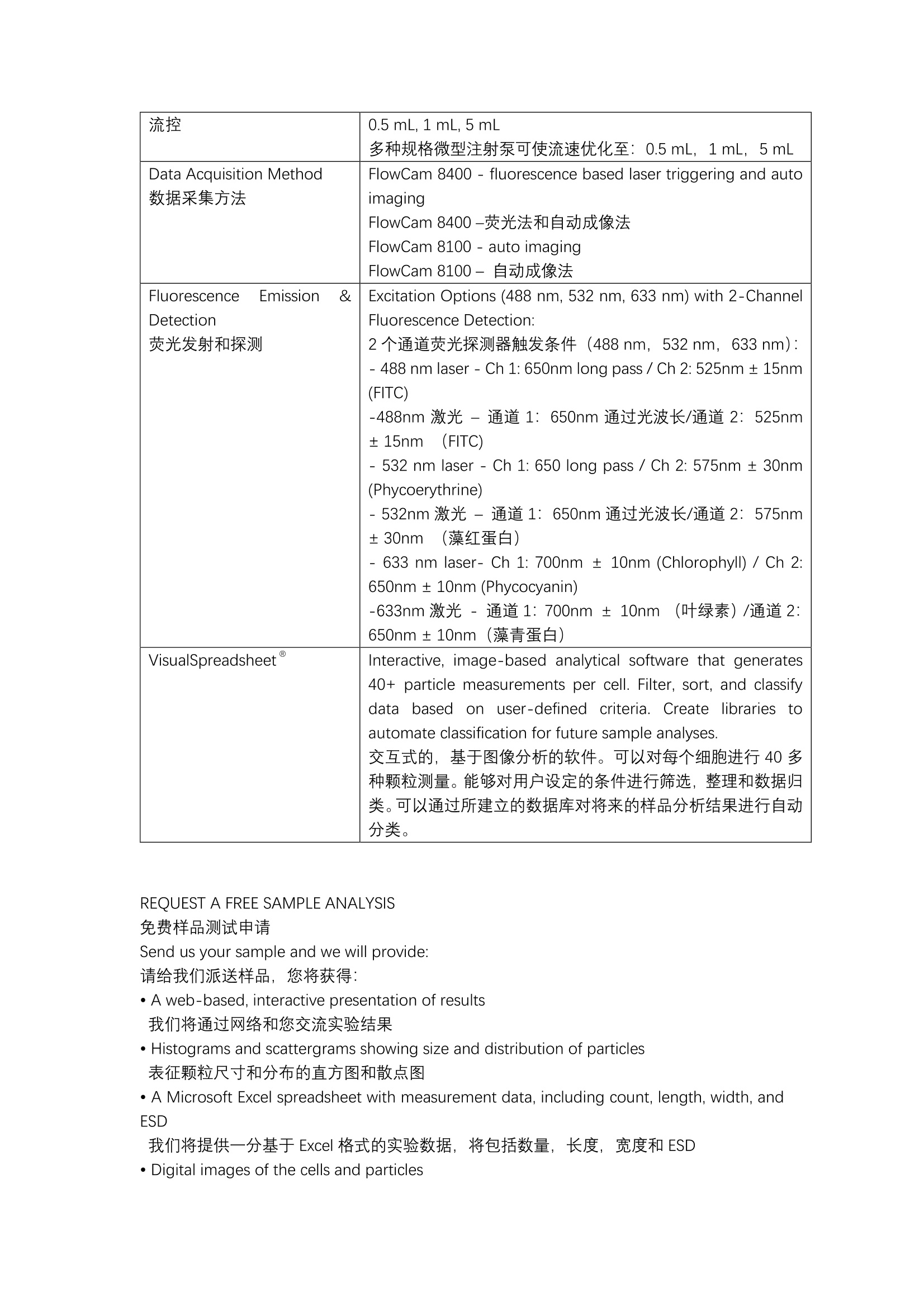

IMAGING PARTICLE ANALYSIS SYSTEM 颗粒成像分析系统 Oil and Gas Applications 用于蛋白质治疗的流式成像显微镜 OVERVIEW 产品概述 With industry-leading image quality combined with automated statistical pattern recognitionsoftware, the FlowCam dynamic imaging particle analysis system is a valuable tool fordetecting, characterizing, and quantifying particles in a variety of oil and gas applications. FlowCam 动态成像颗粒分析系统具有行业领先成像质量和自动识别统计的软件,是检测,表征和定量各种油气行业应用的有效工具。 ·Analyze tens of thousands of particles per minute - get statistically relevant results quickly每分钟分析数以万计的颗粒-能够快速统计相关结果 ·Measure over 40 physical parameters for each imaged particle 能够对所成像的每个颗粒进行40多种物理参数测量 · Get accurate counts for particle counts and morphological measurements for particles 1 umto 600 um 能够准确地获得颗1 um 到600 um 颗粒的计数和形态 · Visually verify your data in real-time with high-quality images-superior image quality leadsto superior image-based particle measurements 高质量的图片可以将实时数据核实可视化-非凡的图像质量可以准备地进行基于图像的颗粒测量。 ·Save time by using automated, trainable,statistically-based pattern recognition softwareto isolate different particles types into categories and sub-populations 使用自动化的,可建模的,基于自动识别统计软件,可将不同的颗粒进行分门别类,从而节省时间。 APPLICATIONS 应用 Drilling mud material characterization 钻探泥浆表征 十 Produced and flowback water analysis 采出水和会流水分析 十 Frac proppant QA/QC 压裂支撑剂的质量控制 十 Hydraulic fluid monitoring 液压油的监测 十 Fuel particle analysis for catfines 燃油中有害残留催化剂的分析 ls it oil or solids? Typical volumetric-based particle analyzers, such as laser diffraction or lightobscuration, do not provide particle shape information. Flow imaging microscopy allows you to see and measure the shape and size of particles. 是油还是固体?典型的粒度分析仪,例如激光衍射法或光透法都无法提供颗粒形状信息。流式成像显微镜可以让你看到和测量到颗粒的形状和尺寸。 Above: Images of oil (top) and solids (bottom) analyzed by the FlowCam 上图:油滴(上)和固体(下)是由 Flow Cam 分析的。 CHARACTERIZE DRILLING MUD 表征钻探泥浆 The size and shape of the particulates in drilling fluid are crititical to the performance of thedrilling operation. With the FlowCam, you can go beyond particle size and closely monitordrilling fluid behavior. The viscosity and rheological characteristics of fluids are directly relatedto the shape of its particulates, therefore the ability to monitor and quantify particle shapeenables proactive, real-time management of drilling fluids. 钻井液中颗粒的大小和形状对钻井作业的效果至关重要。有了 FlowCam,你不仅可以获得颗粒尺寸,还可以密切监测钻井液的动向。流体的粘度和流变特性与其颗粒的形状直接相关,因此,监测和量化颗粒形状能够对钻井液进行主动,实时的管理。 OUANTIFY OIL IN PRODUCED AND FLOWBACK WATER 评价采出水和回流水中的油滴 The FlowCam can help you improve the accuracy and characterization of oil volume inproduced aand fracflowbackwater.TheFlowCam'sSintelligent analysisIssoftwareVisualSpreadsheetQ can automatically distinguish oil droplets from other particulates basedon particle shape measurements. FlowCam 可以帮助你提高检测的准确性,并采出和断裂反对水中含油量进行表征。FlowCam的智能分析软件 VisualSpreadsheet可以自动地通过颗粒形状测量从其他颗粒物中区分出油滴。 QUALITY CONTROL AND ASSURANCE OF FRAC PROPPANTS 压裂支撑剂的质量控制 Frac proppant particles affect the production performance of a well due to their effect onconductivity. Flow imaging microscopy provides an accurate and automated way to evaluatethe sphericity of particles. This method can provide you with the timely and accurateinformation you need to ensure the quality of your frac proppant. 压裂支撑剂颗粒由于其导电性的特性影响了油井的产量。流式成像显微镜提供了一种精确和自动化的方法来评估颗粒的球形度。这种方法可以为你提供及时准确的信息,确保压裂支撑剂的质量。 HYDRAULIC FLUID MONITORING 液压油的监测 Proactive contaminant monitoring in your hydraulic fluids can keep your system runningefficiently. Flow imaging microscopy can quickly detect particles ranging from 1 um to 10 um,particulates typically too small to be filtered out. The FlowCam provides you with immediateconcentration counts and summary statistics of numerous parameters on all particulates. 对液压油中的污染物监测可以使系统保持高效戏行。流式成像显微镜可以快速地探测到1um 到 10 um 粒径的颗粒,太小的颗粒通常都会被过滤掉。FlowCam 为您提供即时的浓度计数和所有颗粒多个参数的汇总统计。 APPLICATION FOCUS: SKIM TANK ANALYSIS USING FLOWCAM 应用方向:使用 Flow Cam 对脱脂罐进行分析 The quality of produced water is important with respect to the efficiency of a well. A treatmentprocess-including skim tanks and filtration systems-is often employed to ensure waterquality is maintained. Using a FlowCam to analyze produced water throughout this processprovides you with greater insight on the quality of your produced water than other typicalmethods. You can calculate realtime particle count reduction and distinguish betweendifferent types of particles. 采出水的质量对于钻井的生产效率是很重要的。通常会使用一种包括脱脂罐和过滤系统的处理工艺来确保水质。使用 FlowCam 来分析整个过程中的采出水可以让您更深入地了解采出水的质量。您可以实时计算颗粒数量的减少和区分不同类型的颗粒。 The images below show that much of the oil was removed within the skim tank, howeversome fouling occurred and some oil droplets were seen in the outlet sample. Filter foulingdownstream in the treatment process can also affect quality, so this data can be helpful fordetermining when filters need to be replaced. Monitoring particle count and characterizationthroughout the produced water treatment process can help ensure water quality and in turnkeep the well running smoothly. The FlowCam makes this easy. 如下图所示,脱脂罐内大部分的油滴已经被清除,但在从出油口提取的样品中出现见一些污垢和油滴。在处理过程中, 下游的过滤器的污垢也会影响水质,因此,这些数据可以帮助判断过滤器何时需要更换。在整个采水处理过程中,监测颗粒数量和特征可以帮助确保水质,从而保证钻井的正常运行。FlowCam 使这一切变得简单。 FLOWCAM 8000 · Minimum sample volume = 100 pl 最小样品量=100 ul ·Auto-rinse and clean cycles prevent crosscontamination 自动清洗和循环清洁功能能够有效避免交叉污染 ·Typical analysis rate = 250 ul/min 标准分析效率 = 250 ul/min ·Compatible with FlowCam Automated Liquid Handling system (ALH) 可以选择配置 FlowCam 自动液体处理系统(ALH) VISUALSPREADSHEET SOFTWARE VISUALSPREADSHEET 软件 · Sort and filter particle data based upon criteria you supply 根据您设定的条件对颗粒数据进行分类和筛选。 · Group all similar particles with sophisticated pattern recognition software capabilities 使用复杂图形识别软件对所有相似颗粒进行分组 ·Create and save user-defined particle type libraries for automatic sorting and statisticalanalysis 通过创建和保存用户自定义的颗粒类型数据库就可以实现自动分类和统计分析 · Instantly calculate summary statistics and interactive graphs 即时计算汇总总计和生成交互图表 FlowCam 8000 Particle Size Range颗粒检测尺寸范围 1 um to 600 um 1um 到 600 um Magnification & FlowCells 20X(~200X magnification), flow cell depth option: 50um 放大倍率和流动池 Field-of-View (FOV) 20X(放大倍数约200X),流动池深度可选:50um可视范围10X(~100X magnification), flow cell depth option: 100 um FOV10X (放大倍数约100X),流动池深度可选:100um可视范围4X (~40X magnification), flow cell depth option: 300 um and600 um FOV 4X(放大倍数约40X),流动池深度可选:300um可视范围 Sample Processing Capability样品量处理能力 0.05 mL/minute at 20X and up to 3mL/minute at 4X使用20倍镜时,0.05毫升/分钟,使用4倍镜时达到3毫升/分钟 Measured Parameters测量参数 Basic Shape Parameters: Area, Aspect Ratio (width/length),Area Based Diameter (ABD), Equivalent Spherical Diameter(ESD), Length, Volume (ABD-based), Volume (ESD-based), Width, 3 Biovolume Measurements基本形状参数:面积,长宽比,基于面积的直径(ABD), 等效圆直径(ESD),长度,体积(基于ABD),体积(基于ESD),宽度,3种细胞体积测量 Advanced Morphology Parameters: Area (Filled), Circle Fit,Circularity, Circularity (Hu), Compactness, Convex Perimeter,Convexity, Elongation, Fiber Curl, Fiber Straightness, GeodesicAspect Ratio, Geodesic Length, Geodesic Thickness, Perimeter,Roughness, Symmetry 高级形态参数:面积(填充),拟合圆,圆度,圆度(Hu),密实度,凸周长,凸度,延伸率,纤维卷曲度,纤维直度,拟合轮廓长宽比,拟合轮廓长度,拟合轮廓厚度,周长,粗糙度,对称性 Fluorescence Detection & Measurements: Channel 1 Area,Channel 1 Peak, Channel 1 Width, Channel 2 Area, Channel 2 Peak, Channel 2 Width, Channel 2/Channel 1 Ratio荧光探测和测量:通道1面积,通道1峰值,通道1宽度,通道2面积,通道2峰值,通道2宽度,通道2/通道1比率Gray Scale and Color Measurements: Average Blue, AverageGreen, Average Red, Edge Gradient, Intensity, Blue/GreenRatio, Red/Blue Ratio, Red/GreenRatio, Edge Gradient,Intensity, Sigma Intensity, Sum Intensity, Transparency灰度和彩色测量:平均蓝,平均绿,边缘梯度,亮度,蓝/绿比 率,红/蓝比率,红/绿比率,边缘梯度,亮度, Sigma 亮度, 亮度总量,透明度 Camera 成像系统 High resolution (1920x1200 pixels) CMOS. Monochrome andcolor available 高分辨率CMOS (1920x1220像素),可获得黑白或彩色图像。 Frame Rate帧率 Shutters up to 100 frames per second. 快门速度可到达100帧/秒。 Fluidics Micro-syringe pump with multiple sizes to optimize flow rates: 流控 0.5 mL, 1 mL, 5 mL 多种规格微型注射泵可使流速优化至:0.5mL, 1 mL, 5 mL Data Acquisition Method数据采集方法 FlowCam 8400 - fluorescence based laser triggering and auto imaging FlowCam 8400-荧光法和自动成像法 FlowCam 8100 - auto imaging FlowCam 8100- 自动成像法 Fluorescence Emission &Detection 荧光发射和探测 Excitation Options (488 nm, 532 nm, 633 nm) with 2-ChannelFluorescence Detection: 2 个通道荧光探测器触发条件 (488nm, 532 nm, 633 nm):-488 nm laser - Ch 1: 650nm long pass / Ch 2: 525nm ±15nm (FITC) -488nm 激光-通道1:650nm 通过光波长/通道2:525nm±15nm((FITC) - 532 nm laser - Ch 1: 650 long pass / Ch 2: 575nm ± 30nm (Phycoerythrine) -532nm激光-通道1:650nm 通过光波长/通道2:575nm± 30nm (藻红蛋白) -633 nm laser- Ch 1: 700nm ± 10nm(Chlorophyll)/ Ch 2:650nm ± 10nm (Phycocyanin) -633nm 激光-通道1:700nm ± 10nm(叶绿素)/通道 2:650nm±10nm(藻青蛋白) VisualSpreadsheetLQ Interactive, image-based analytical software that generates 40+ particle measurements per cell. Filter, sort, and classify databasedon user-defined criteria. Createlibraries toautomate classification for future sample analyses.交互式的,基于图像分析的软件。可以对每个细胞进行40多种颗粒测量。能够对用户设定的条件进行筛选,整理和数据归类。可以通过所建立的数据库对将来的样品分析结果进行自动分类。 REQUEST A FREE SAMPLE ANALYSIS 免费样品测试申请 Send us your sample and we will provide: 请给我们派送样品,您将获得: · A web-based, interactive presentation of results 我们将通过网络和您交流实验结果 · Histograms and scattergrams showing size and distribution of particles 表征颗粒尺寸和分布的直方图和散点图 ·A Microsoft Excel spreadsheet with measurement data, including count, length, width, andESD 我们将提供一分基于 Excel格式的实验数据,将包括数量,长度,宽度和 ESD ·Digital images of the cells and particles 细胞和颗粒的数码图片 产品概述动态成像颗粒分析系统具有行业领先成像质量和自动识别统计的软件,是检测,表征和定量各种油气行业应用的有效工具。• 每分钟分析数以万计的颗粒 – 能够快速统计相关结果• 能够对所成像的每个颗粒进行40多种物理参数测量• 能够准确地获得颗1 µm到600 µm颗粒的计数和形态• 高质量的图片可以将实时数据核实可视化 – 非凡的图像质量可以准备地进行基于图像的颗粒测量。• 使用自动化的,可建模的,基于自动识别统计软件,可将不同的颗粒进行分门别类,从而节省时间。上图:油滴(上)和固体(下)是由Flow Cam分析的是油还是固体?典型的粒度分析仪,例如激光衍射法或光透法都无法提供颗粒形状信息。流式成像显微镜可以让你看到和测量到颗粒的形状和尺寸。表征钻探泥浆钻井液中颗粒的大小和形状对钻井作业的效果至关重要。有了FlowCam,你不仅可以获得颗粒尺寸,还可以密切监测钻井液的动向。流体的粘度和流变特性与其颗粒的形状直接相关,因此,监测和量化颗粒形状能够对钻井液进行主动,实时的管理。评价采出水和回流水中的油滴FlowCam可以帮助你提高检测的准确性,并采出和断裂反对水中含油量进行表征。FlowCam的智能分析软件VisualSpreadsheet®可以自动地通过颗粒形状测量从其他颗粒物中区分出油滴。压裂支撑剂的质量控制压裂支撑剂颗粒由于其导电性的特性影响了油井的产量。流式成像显微镜提供了一种精确和自动化的方法来评估颗粒的球形度。这种方法可以为你提供及时准确的信息,确保压裂支撑剂的质量。液压油的监测对液压油中的污染物监测可以使系统保持高效运行。流式成像显微镜可以快速地探测到1 µm到10 µm粒径的颗粒,太小的颗粒通常都会被过滤掉。FlowCam为您提供即时的浓度计数和所有颗粒多个参数的汇总统计。应用方向:使用Flow Cam对脱脂罐进行分析采出水的质量对于钻井的生产效率是很重要的。通常会使用一种包括脱脂罐和过滤系统的处理工艺来确保水质。使用FlowCam来分析整个过程中的采出水可以让您更深入地了解采出水的质量。您可以实时计算颗粒数量的减少和区分不同类型的颗粒。如下图所示,脱脂罐内大部分的油滴已经被清除,但在从出油口提取的样品中出现了一些污垢和油滴。在处理过程中,下游的过滤器的污垢也会影响水质,因此,这些数据可以帮助判断过滤器何时需要更换。在整个采水处理过程中,监测颗粒数量和特征可以帮助确保水质,从而保证钻井的正常运行。FlowCam使这一切变得简单。

确定

还剩4页未读,是否继续阅读?

大昌华嘉科学仪器为您提供《石油和天然气中表征和定量检测方案(图像粒度粒形)》,该方案主要用于天然气/燃气中理化分析检测,参考标准--,《石油和天然气中表征和定量检测方案(图像粒度粒形)》用到的仪器有流式颗粒成像分析系统FlowCam®8100、流式颗粒成像分析系统FlowCam Macro、颗粒成像法+光阻法分析系统 FlowCam® + LO

该厂商其他方案

更多