方案详情

文

ERAFLASHTM和ERAFLASH S10TM闪点仪具有创新性、可靠性、通用性、安全性和易操作性。测试人员需要非常少的样品量,并在几分钟内自动执行测量,可以多达每小时12个样品的检测量。ERAFLASHTM可存储超过100000份详细的测试报告,并具有与最重要的ASTM、ISO和其他国际标准测试方法的预编程关联方法。此外,它在最大温度范围提供了最大的效率,允许更多的应用,包括易挥发性和有价值的材料,如香料,甚至危险废物材料。

方案详情

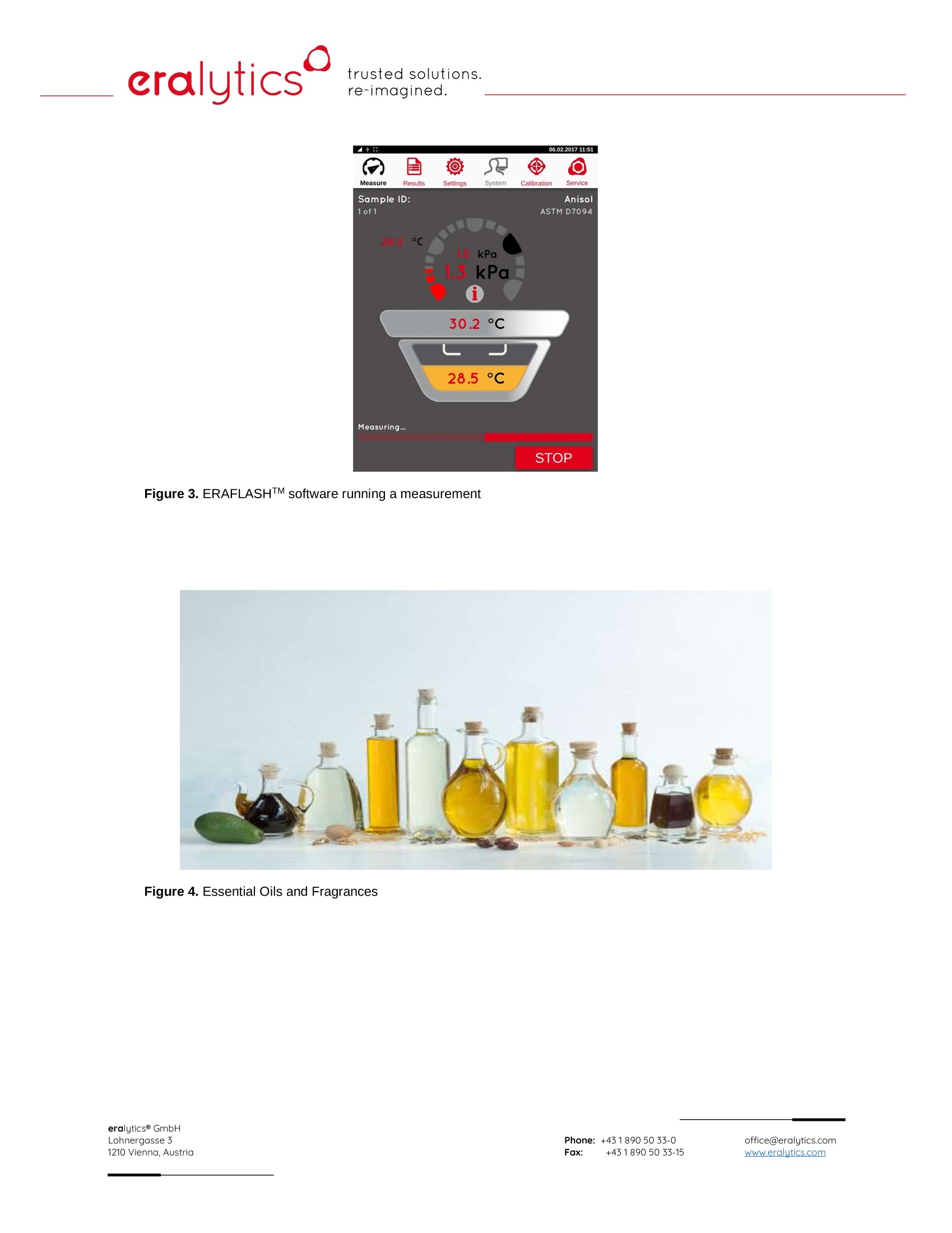

eralyticstrusted solutions.re-imagined. Flash Point determination in Food, Flavors and Fragrances ERAFLASHTM, an essential and reliabletool to guarantee both product quality andtransportation safety. A. Mendez Ph.D. Ayalytical Instruments Inc.2787 W Fulton Street Chicago Il 60612 USAaaron@ayalytical.com Introduction Engineers and scientists of the food, flavors and fragrances industries are faced with many difficult tasksto control the quality of their processes, raw materials, intermediates and final products and to guaranteethe consistency of production1.Identifying changes in process parameters that may lead to changes inquality, as well as detecting adulteration in any ingredient in cases of fraud and unfair competition areexamples of these challenges. Quality in these industries is a fairly abstract term since it involves aromas,freshness, shelf live, compatibility with other volatile substances in fact it is a parameter that is verydifficult to quantify. There is a need to establish a profile or finger print in which the measure of volatilitythrough its flash point is becoming imperative. Flash Point is by definition, the lowest temperature at which the vapors of a volatile material will ignite inthe proximity of an ignition source. Flash Point serves as a tool to classify materials as flammable orcombustible. The classification of your material will affect many requirements including labeling, storagerequirements, shipping requirements and disposal. Therefore, measuring the flash point is necessary to establish appropriate safety measures oftransportation of volatile organic compounds, under which flavors, essential oils and fragrances fall into.The classification of fuels and other volatile materials by their flash point or flammability is a very old andwell-established practice. Today the flash point is defined in numerous international standard testmethods and measured by instruments using either 'open cup'or 'closed cup'apparatus as described inTable 1. For many years the two traditional flashpoint methods ASTM D56 (TAG method) and ASTM D93(Pensky-Martens method) were extensively utilized. Both methods share a common principle: 70-75 mlof sample is heated, in a specified interval, the lid of the cup is opened, and a test flame or glowing wireis lowered into the vapor space above the liquid to test whether the vapor ignites. The ERAFLASHTM basic apparatus, shown in fig.1, or the automatic unit equipped with an S10autosampler shown in fig.2 determine the flash point differently and in a modern way. It follows theASTM D64502and the newer ASTM D7094 Standard “Test Method for Flash Point by the ModifiedContinuously Closed Cup (MCCCFP) Tester"3. Due to its continuously closed cup design and the smallamount of sample required for the test, ERAFLASHTM completely eliminates the risk of fire in thelaboratory. Figure 1. The ERAFLASHTM Flash Point analyzer basic unit. Combined with the patented PBT- Peltier Boost TechnologyTM, flash points for VOCs can quickly andsafely be analyzed within minutes with quick cool down rates4. The flash point is detected by monitoringthe pressure increase after the ignition inside the closed measuring chamber, completely preventing therisk of fire. The flame is extinguished automatically due to a lack of oxygen inside the chamber. The Peltier elements are arranged above the measuring chamber following a revolutionary conceptdeveloped by eralytics. Paired with the conveniently small size (1-2 ml) of the continuously closed samplecup design (CCCFP) this new concept allows for extremely safe flashpoint tests over the full requiredtemperature range of -25 to 420℃ (-13 to 788°F) in a single portable ERAFLASHTM flashpoint tester.Additionally, the high-speed heating and cooling technology significantly reduces the run time, makingflashpoint testing more economical than ever before The PBT technology is especially suited for flavors and fragrances where most of them are of very volatilenature, constituted by complex mixtures that are costly and produced in small quantities and kept involatile liquid phase5 as illustrated in Fig. 3. The requirement of just 1 - 2 mL of sample amount forflashpoint testing is indeed very beneficial for these types of products. ERAFLASH's results thoroughlycorrelate to D56, D93 and D3828 and their respective ISO standards 2719,13736,3679 and 3680. Maximum Safety Flash point, according to European and American Safety Regulations Agencies, is a vital parameter tobe reported. ‘Closed cup'instruments are more often specified as the instrument of choice, because thetest results are less affected by laboratory conditions and give a more precise and safer result. To judgethe fire hazard of a chemical also highly volatile components have to be taken into account. ‘Closed cup’results take these volatiles into account and therefore always lower results than ‘open cup'results wherevolatiles are lost during the heat up phase. All these characteristics serve the most relevant purpose: a properly determined flash point avoids therisk of underestimating the hazardousness of the measured material and ensures the correctclassification, which otherwise could lead to financial penalties. High Throughput One additional benefit of the safest flash point testing method is that it is also safe when used forautomating flash point measurements. ERAFLASH S10TM is the bigger brother of ERAFLASHTMenabling the unattended measurement of up to 10 samples. The samples are loaded on a tray and arealways covered by a lid which can be seen in figure 2. This lid can optionally be cooled which furtherreduces the evaporation losses of highly volatile material prior to the measurement. Figure 2. New ERAFLASHTM with S10 Autosampler. This automation is of special interest for QC labs of flavors and fragrances companies since they areproducing many different substances all of which need measured flash point for the safety data sheetthat must accompany every shipment. Bigger producers can easily face 100-200 flash point samples aday which can take up a significant amount of lab technician time if measured on a single position unit. Automating these time-consuming measurements increases the efficiency in such environmentssignificantly. And all that is possible without any bad feelings concerning safety issues. eralytics trusted solutions. re-imagined. Figure 3. ERAFLASHTM software running a measurement Figure 4. Essential Oils and Fragrances Experimental Results ERAFLASHTM displays and stores combustion characteristics of products facilitating detection ofcontamination and adulteration of products of enormous significance in the food, flavor and fragrancesindustry. The Globally Harmonized System (GHS) of Classification and Labelling of Chemicals categorizes theflammable liquid criteria according the following flash point ranges: Criteria GHS Category Transport Class/PackingGroup Flash Point <73F (23℃)& Initial boiling point <95°F(35℃ 1 3,1 Flash Point <73℉ (23C) & Initial boiling point <95°F(35°C 2 3,I Flash Point ≥73°F (23C) & ≤140F (60℃) 3 3, Il Flash Point >140F (60℃) & ≤200°F (93.3℃) 4 Combustible liquid, Ⅲ Table 1. Classification of Volatile materials Two types of samples were analyzed with the ERAFLASHTM instrument according to D7094 method: Aseries of 5 essential oils presented in Table 2 and 9 raw materials like moisturizing and fragranceadditives listed in Table 3. Both types of raw materials are used in the perfume and cosmetic industry.Flash point results of essential oils and fragrances listed in table 2 were determined in triplicates in orderto display the dispersion and repeatability of the tests. The results shown in Table 3, list a series of“No Flash” results primarily due to the considerable watercontent typical for hand & body creams or other additives & raw materials used in the cosmeticindustry. Table 3 also compares two different types of measurement results: SCAN and ASTM D7094. Tomeasure a flash point according to ASTM D7094 an expected flash points needs to be known. Ifthis isnot possible then the SCAN method can be used over a broad temperature range to determine theapproximate flash point to be used afterwards for the ASTM D7094 measurement. Run # Sample ID Pamb (kPa) Flash Point(C) Corr. FP(C) MeanValue (C) %RSD STDEV 1 Sample 1 99.6 59 59.42 59.08 0.58 0.99 2 Sample 1 99.6 59 59.42 3 Sample 1 99.7 58 58.41 4 Sample 2 98.6 59 59.66 60.33 0.58 0.96 5 Sample 2 98.6 60 60.66 6 Sample 2 98.6 60 60.66 7 Sample 3 98.7 58 58.65 58.65 0.01 0.02 8 Sample 3 98.8 58 58.64 9 Sample 3 98.7 58 58.66 10 Sample 4 98.9 59 59.59 59.54 0.05 0.08 11 Sample 4 99.2 59 59.53 12 Sample 4 99.3 59 59.50 13 Sample 5 99.1 50 50.55 49.88 0.58 1.16 14 Sample 5 99.1 49 49.56 15 Sample 5 99.1 49 49.54 Table 2. Flash Point on Essential Oils EXPERIMENTAL RESULTS Run# Sample ID Sample Type SCAN (℃) ASTMD7094(C) 1 Sample 6 colorless liquid 100 100.4 2 Sample 7 colorless liquid 104 104.5 34 Sample 8 white cream No Flash No FlashNo Flash 5 Sample 9 Sample 10 orange- viscous liquidbeige cream No Flash 60 58.5 6 Sample 11 white pellets 196 188.5 7 Sample 12 beige cream 60 58.5 8 Sample 13 beige cream No Flash No Flash 9 Sample 14 beige cream No Flash No Flash 10 Sample 15 dark-blue cream No Flash No Flash Table 3. Flash Points of Cosmetics Conclusions ERAFLASHTM and ERAFLASH S10TM testers are innovative, reliable, versatile, safe and easy tooperate. The testers require a very small amount of sample and automatically perform the measurementin minutes, representing a throughput of up to 12 samples per hour. ERAFLASHTM can store more than100000 detailed test reports and has pre-programmed correlation methods to the most significantASTM, ISO and other international standard test methods. Furthermore, it provides for maximumefficiency under the amplest temperature ranges to allow for more applications including very volatileand valuable materials, such as fragrances and even hazardous waste materials. References 1. Herman, S.J. Chemistry and Technology of Flavors and Fragrances. Chapter 13,BlackwellPublishing. 2ASTM D6450 Annual Book of Standards Vol. 05.03 January 2016.34 ASTM D7094 Annual Book of Standards vol. 05.03 January 2016. Dr. C. Wagner & A. Schwarzmann. ASTM D7094_ MCCFP Standard Accepted as a SafeAlternative Method in Various Fuel Specs. Petr Industry News Feb/March 2014. 5. K.H. C. Baser & Temel Ozek. Analysis of Essential Oils and Fragrances by GasChromatography Chapter 22. Gas Chromatography 1st Ed.Elsevier Inc., 2012. eralytics GmbHLohnergasseVienna, AustriaPhone: + office@eralytics.comFax: + www.eralutics.com 介绍 食品、香精和香料行业的工程师和科学家面临着许多困难的任务,比如:工艺控制、原材料、中间体和最终产品的质量,以及保证产品的一致性。识别可能导致质量变化的工艺参数变动,以及在欺诈和不正当竞争案件中发现任何掺假的成分,就是这些挑战的例子。在这些行业中,质量是一个相当抽象的术语,因为它涉及到芳香、新鲜度、保质期以及其他挥发性物质的相容性。事实上,它是一个很难量化的参数。所以,这些行业中有必要建立一个指纹验证,其中,通过其闪点测定来衡量波动性已成为当务之急。 闪点的定义是,挥发性物质的蒸汽与外界空气形成混合气,在与火焰接触时发生闪火并立刻燃烧的最低温度。闪点测定可作为将材料分类为易燃或可燃的工具。材料的分类将影响标签、储存要求、运输要求和处置等方面。 因此,测定闪点是建立挥发性有机物运输安全措施的必要条件,挥发性有机物是香料、香精油的主要成分。按闪点对燃料和其他易挥发物质进行分类是一种非常传统和公认的做法。现在,闪点检测有很多国际标准试验方法,多年来,两种传统的闪点测试方法ASTM D56(泰格法)和ASTM D93(宾斯基马丁法)得到了广泛的应用。两种方法都有一个共同的原理:加热70-75ml样品,在规定的时间间隔内打开杯盖,将测试火焰或灼热丝放入液体上方的蒸气空间,以测试蒸气是否被点燃。 图1所示的ERAFLASH单杯仪器,图2所示配备10位自动采样器的ERAFLASH S10,都可以不同的测试方法进行闪点的测定。它采用ASTM D6450和更新的ASTM D7094标准“用改进的连续闭杯(MCCCFP)测试仪测定闪点的试验方法”。ERAFLASHTM采用连续闭杯设计,测试所需样品量小,完全消除了实验室火灾的风险。图 1. 连续闭杯检测单杯仪器ERAFLASHTM 结合专利PBT-Peltier Boost(帕尔贴)技术™,可在几分钟内快速安全地进行闪点分析,并具有快速冷却速度。在密闭的测量室内,通过监测点火后压力的瞬间升高来检测闪点,完全防止了火灾的危险。由于测量室内缺氧,火焰自动熄灭。 念帕尔贴元件布置在测量室上方,这是由eralytics提出的革命性改进。与方便的小尺寸(1-2毫升)的连续闭式样品杯设计(CCCFP)相结合,这种新理念允许在单杯便携式ERAFLASHTM闪点测试仪中,在-25至420°C(-13至788°F)的完整要求温度范围内进行极为安全的闪点测试。此外,高速加热和冷却技术大大缩短了运行时间,使闪点测试比以往任何时候都更快速高效。 PBT技术特别适用于香精和香料,其中大多数香精和香料具有极易挥发的轻组分,由复杂的混合物构成,这些混合物成本高,生产量小,保存在挥发性液相中。闪点测试只需要1-2毫升的样品量,这样的小样品量对这类产品确实非常有利。ERAFLASH的结果与ASTM D56,D93和D3828及ISO标准2719、13736、3679和3680具有完全的相关性。 最大的安全性根据欧洲和美国安全法规机构的要求,闪点是一个需要报告的重要参数。“闭杯”闪点仪通常被指定为首选仪器,因为测试结果受实验室条件的影响较小,并能给出更精确和更安全的结果。为了判断一种化学品的火灾危险性,还必须考虑高挥发性成分。“完全闭杯”的结果考虑了这些挥发物,因此总是低于“开放闭杯”闪点仪(虽然也是闭杯,但在点火时会开盖)的结果,即挥发物在加热阶段损失。所有这些特性都是最重要的目的:确定最准确的闪点,避免低估被测材料的危险性,并确保正确分类,否则可能导致经济处罚。高通量最安全的闪点测试方法的另一个好处是,当用于自动闪点测量时,它也是非常安全的。ERAFLASH S10TM,可实现多达10个样品的无人值守测量。样品杯装在托盘上,并始终由顶盖密闭,如图2所示。该盖子可选配冷却盖,从而进一步减少测量前高挥发性物质的蒸发损失。图 2. 配备10位自动进样器的ERAFLASH S10TM香精香料公司的QC实验室对这种自动化特别感兴趣,因为他们生产许多不同的产品,所有这些产品在装运时必须附带包括闪点测量在内的安全数据表格。较大的生产商利用ERAFLASH S10,一天可以很容易地检测100-200个闪点样品,并且可以节省大量的实验室技术人员的时间。这些耗时的测量采用自动化检测大大提高了效率,而且不会对安全问题产生任何负面影响。图 3. ERAFLASHTM 操作界面图 4. 香料和精油实验数据ERAFLASHTM显示和存储产品的燃烧特性,有助于检测食品、香精和香料行业中具有重大意义的产品污染和掺假。《全球化学品统一分类和标签制度》(GHS)根据以下闪点范围对易燃液体标准进行了分类:闪点范围GHS 类别运输级别/包装分组闪点 <73°F (23°C) &初沸点 ≤95°F(35°C)13, I闪点<73°F (23°C) &初沸点>95°F(35°C)23, II闪点 ≥73°F (23°C) & ≤140°F (60°C)33, III闪点 >140°F (60°C) & ≤200°F (93.3°C)4可燃液体, III表1. 挥发性物质分类根据ASTM D7094方法,使用ERAFLASHTM对两种样品进行分析:表2所示的5种精油系列和表3所列的9种原料,如保湿剂和香料添加剂。这两种原料都用于香水和化妆品行业。为了显示试验的分散性和重复性,将表2所列精油和香料的闪点结果分为三份进行测定。 结果如表3所示,列出了一系列“无闪点”的结果,主要是因为手霜、身体霜、化妆品行业使用的其他添加剂和原材料的含水量相当大。 表3还比较了两种不同类型的测量结果:快速扫描(SCAN)和ASTM D7094。根据ASTM D7094测量闪点,需要知道预期闪点。如果预闪点未知,那么快速扫描方法(SCAN)可以在较宽的温度范围内使用,以确定随后用于ASTM D7094测量的预期闪点。序号 样品序号闪点 (oC)校正后闪点(oC)平均值(oC) 相对标准偏差标准偏差1Sample 15959.4259.080.580.992Sample 15959.423Sample 15858.414Sample 25959.6660.330.580.965Sample 26060.666Sample 26060.667Sample 35858.6558.650.010.028Sample 35858.649Sample 35858.6610Sample 45959.5959.540.050.0811Sample 45959.5312Sample 45959.5013Sample 55050.5549.880.581.1614Sample 54949.5615Sample 54949.54Table 2. 精油闪点检测实验结果序号样品序号样品类别SCAN (°C)ASTMD7094 (°C)1Sample 6无色液体100100.42Sample 7无色液体104104.53Sample 8白奶油无闪点无闪点4Sample 9橙色黏性液体无闪点无闪点5Sample 10米色奶油6058.56Sample 11白色颗粒196188.57Sample 12米色奶油6058.58Sample 13米色奶油无闪点无闪点9Sample 14米色奶油无闪点无闪点10Sample 15深蓝奶油无闪点无闪点Table 3. 化妆品闪点检测 结论ERAFLASHTM和ERAFLASH S10TM闪点仪具有创新性、可靠性、通用性、安全性和易操作性。测试人员需要非常少的样品量,并在几分钟内自动执行测量,可以多达每小时12个样品的检测量。ERAFLASHTM可存储超过100000份详细的测试报告,并具有与最重要的ASTM、ISO和其他国际标准测试方法的预编程关联方法。此外,它在最大温度范围提供了最大的效率,允许更多的应用,包括易挥发性和有价值的材料,如香料,甚至危险废物材料。典型用户

确定

还剩5页未读,是否继续阅读?

培安有限公司为您提供《食品、香精、香料中闪点检测方案(闪点仪)》,该方案主要用于香精香料中闪点检测,参考标准--,《食品、香精、香料中闪点检测方案(闪点仪)》用到的仪器有Eraflash S10 全自动十杯微量闪点仪、ERAFLASH 全自动微量闪点仪

相关方案

更多

该厂商其他方案

更多