方案详情

文

在高温滴定系统下使用液滴形状分析计算不同热熔胶表面张力及PTFE上的接触角,得到表面张力的极性和非极性部分以及粘附功等。

方案详情

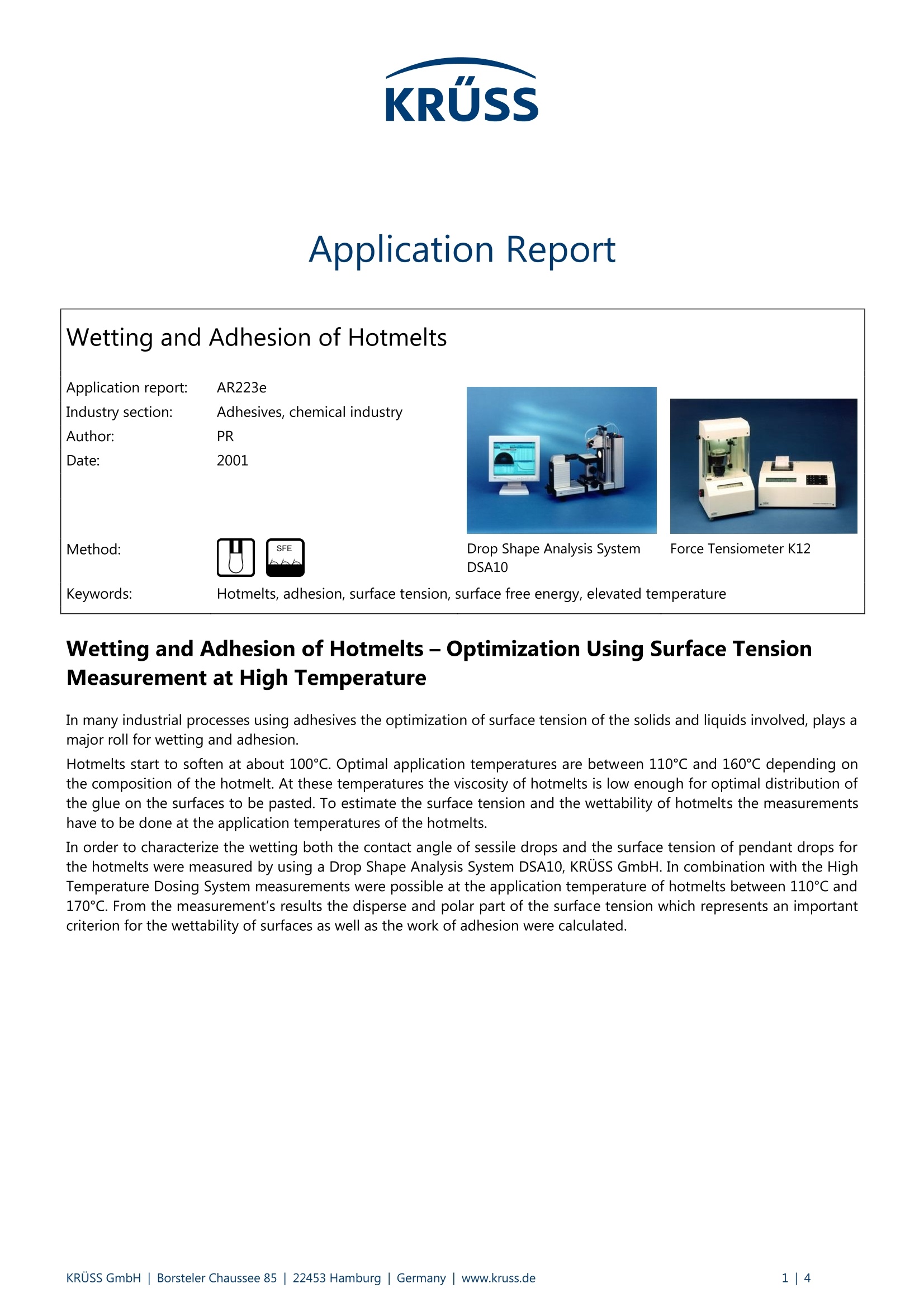

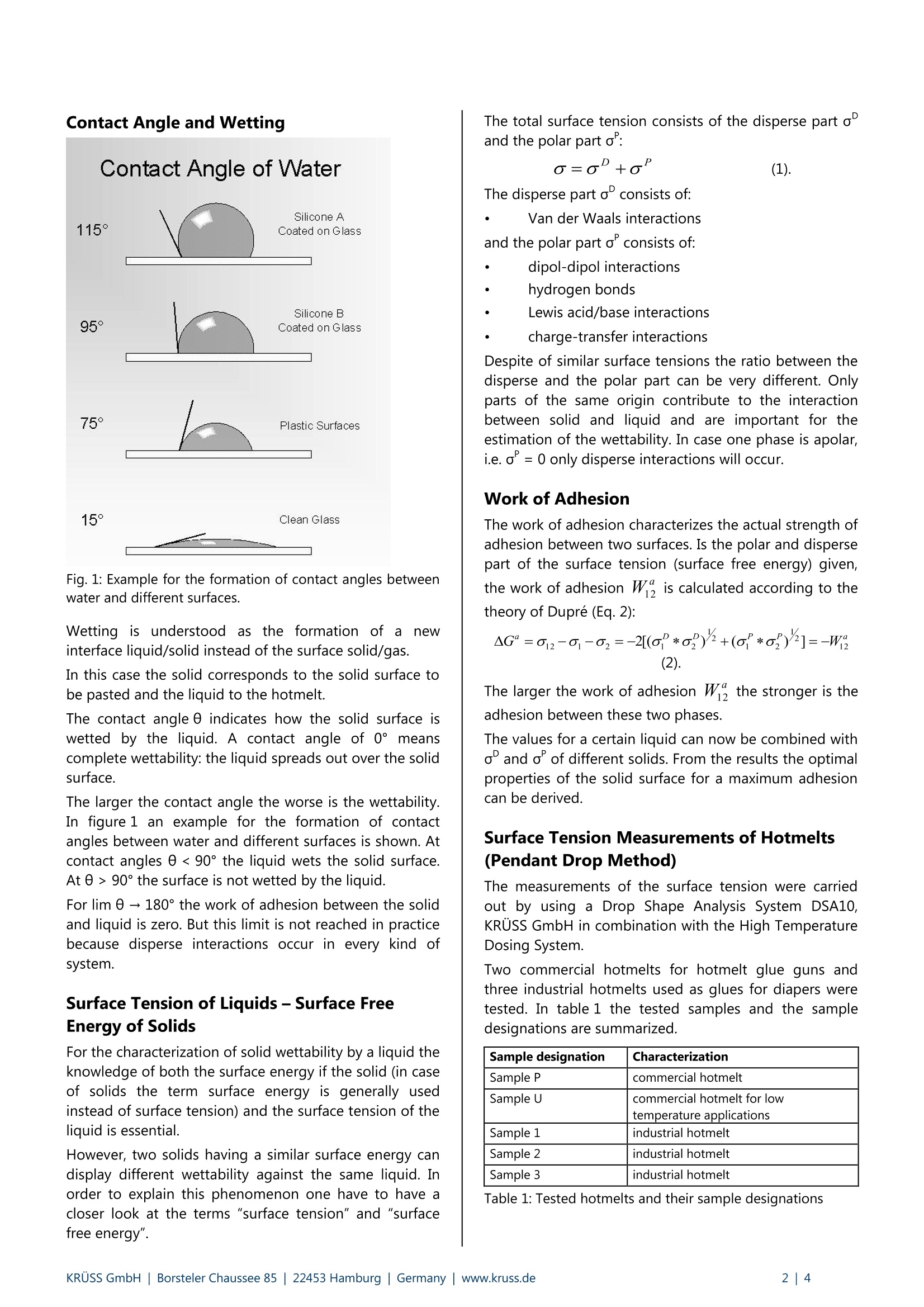

KRUSS Application Report Wetting and Adhesion of Hotmelts Application report: AR223e Industry section: Adhesives, chemical industry Author: PR Date: 2001 Method: SFE Drop Shape Analysis System Force Tensiometer K12 AAA DSA10 Keywords: Hotmelts, adhesion, surface tension, surface free energy, elevated temperature Wetting and Adhesion of Hotmelts -Optimization Using Surface TensionMeasurement at High Temperature In many industrial processes using adhesives the optimization of surface tension of the solids and liquids involved, plays amajor roll for wetting and adhesion. Hotmelts start to soften at about 100°℃. Optimal application temperatures are between 110℃ and 160℃ depending onthe composition of the hotmelt. At these temperatures the viscosity of hotmelts is low enough for optimal distribution ofthe glue on the surfaces to be pasted. To estimate the surface tension and the wettability of hotmelts the measurementshave to be done at the application temperatures of the hotmelts. In order to characterize the wetting both the contact angle of sessile drops and the surface tension of pendant drops forthe hotmelts were measured by using a Drop Shape Analysis System DSA10, KRUSS GmbH. In combination with the HighTemperature Dosing System measurements were possible at the application temperature of hotmelts between 110℃ and170℃. From the measurement’s results the disperse and polar part of the surface tension which represents an importantcriterion for the wettability of surfaces as well as the work of adhesion were calculated. Contact Angle and Wetting Fig. 1: Example for the formation of contact angles betweenwater and different surfaces. Wetting is understood asasthe formation of aanewinterface liquid/solid instead of the surface solid/gas. In this case the solid corresponds to the solid surface tobe pasted and the liquid to the hotmelt. The contact angle 0 indicates how the solid surface iswetted by the liquid. A contact angle of 0° meanscomplete wettability: the liquid spreads out over the solidsurface. The larger the contact angle the worse is the wettability.In figure 1 an example for the formation of contactangles between water and different surfaces is shown. Atcontact angles 0 <90° the liquid wets the solid surface.At O > 90° the surface is not wetted by the liquid. For lim0→180° the work of adhesion between the solidand liquid is zero. But this limit is not reached in practicebecause disperse interactions occur in every kind ofsystem. Surface Tension of Liquids-Surface FreeEnergy of Solids For the characterization of solid wettability by a liquid theknowledge of both the surface energy if the solid (in caseof solids the term surface energy is generally usedinstead of surface tension) and the surface tension of theliquid is essential. However, two solids having a similar surface energy candisplay different wettability against the same liquid. Inorder to explain this phenomenon one have to have acloser look at the terms "surface tension" and "surfacefree energy". The total surface tension consists of the disperse part o"and the polar part o: The disperse part oconsists of: Van der Waals interactions and the polar part o"consists of: dipol-dipol interactions hydrogen bonds Lewis acid/base interactions charge-transfer interactions Despite of similar surface tensions the ratio between thedisperse and the polar part can be very different. Onlyparts of the same origin contribute to the interactionbetween solid and liquid and are important for theestimation of the wettability. In case one phase is apolar,i.e. o"=0 only disperse interactions will occur. Work of Adhesion The work of adhesion characterizes the actual strength ofadhesion between two surfaces. Is the polar and dispersepart of the surface tension (surface free energy) given,the work of adhesion W is calculated according to thetheory of Dupre (Eq.2): The larger the work of adhesion W" the stronger is theadhesion between these two phases. The values for a certain liquid can now be combined witho and o" of different solids. From the results the optimalproperties of the solid surface for a maximum adhesioncan be derived. Surface Tension Measurements of Hotmelts(Pendant Drop Method) The measurements of the surface tension were carriedout by using a Drop Shape Analysis System DSA10,KRUSS GmbH in combination with the High TemperatureDosing System. Two commercial hotmelts for hotmelt glue guns andthree industrial hotmelts used as glues for diapers weretested. In table 1 the tested samples and the sampledesignations are summarized. Sample designation Characterization Sample P commercial hotmelt Sample U commercial hotmelt for low temperature applications Sample 1 industrial hotmelt Sample 2 industrial hotmelt Sample 3 industrial hotmelt Table 1: Tested hotmelts and their sample designations Fig. 2: Video frame of a pendant drop, Sample U, 110℃ By using the method of Pendant Drop (fig. 2) the surfacetension of hotmelts were estimated in dependence ondrop age and on temperature in the range from 110℃and 170℃,depending0onthe current hotmeltcomposition. The drop was recorded by a video camera and the dropshape was analyzed by the software DSA1, KRUSS GmbHusing the Young-Laplace equation. In result the surfacetension was obtained. The results are summarized intable 2. Sample Tempe-rature[C] Surfacetension a[mN/m] Contactangle01[] Dispersepart o[mN/m' Polar part [mN/m] SampleP 120 44,31 58,9 44,31 0 SampleU 120 43,81 54,3 54,3 0 Sample1 120 28,94 49,6 28,44 0,5 130 27.79 47.3 27,79 0.31 140 27,13 46,8 26,11 1,02 150 25.92 47,3 23,65 2,27 160 25.19 48,4 21,96 3,23 Sample2 120 24,20 55,6 17,93 6,27 130 23.26 54,8 16,80 6,45 140 22,62 56,5 15,40 7,22 150 21.94 56,8 14,41 7,53 160 20.75 57,4 12,74 8,00 Sample3 130 27,81 60,6 21,49 6,32 140 26,04 60,7 18,78 7,24 150 24,76 61,0 16,90 7,86 Table 2: Surface characteristics of hotmelts The commercial hotmelts showed ;a higher surfacetension in comparison to the industrial hotmelts. Theindustrial hotmelts (sample 1 to 3) have a significanttemperature dependence. With increasing temperaturethe surface tension decreases (Tab.2). The surface tension was also measured in dependenceon time (Fig.3). Clear differences in the dependence ofthe surface tension on the drop age were registered. Inopposite to sample 1 and 3 sample 2 showed a constantsurface tension with increasing drop age. Fig. 3:Dependence of the surface tension on the drop agefor sample 1 to 3 at 130℃ Contact Angle Measurements of hotmelts onPTFE (Sessile Drop Method) The used equipment and tested samples were the sameas for the measurements in the previous chapter. Usingthe High Temperature Dosing System a drop was givenon PTFE and the right and left contact angle wasestimated. To fit the drop shape the Tangent 1- andTangent 2-Method was chosen in the software DSA1. In table 2, column 4 the estimated contact angles aresummarized. All contact angles are smaller than 90°especially sample 2 showed low contact angles and goodwettability on PTFE. Fig. 4: Contact angle measurements of a sessile drop,sample U, 130° Using the surface tension and contact angle on PTFE thedisperse part can be calculated for each sample independence on temperature (Eq.3-): where o is the disperse part of the liquid (hotmelt), athe surface tension of the liquid, o, the surface tension ofthe apolar solid (PTFE) and 0 the contact angle of theliquid on the apolar solid. The polar part results from thedifference of the total surface tension minus the dispersepart. In table 2 the polar and disperse part of the surfacetension for different hotmelts are summarized. Samples P, U and 1 have only small polar parts, whereasfor sample 2 and 3 the polar parts are significantlyhigher. Calculation of the Work of Adhesion From the polar and disperse part of the surface tensionof hotmelts the work of adhesion for different solidsurfaces can be calculated, provided that the polar anddisperse parts of the solids are known. Exemplary thework of adhesion was calculated for sample 1 at 140℃ incombination with different solid surfaces which are oftenused in practice (table 3). The values of the work of adhesion are particularly highfor glass, PMMA and PET. All these substances display alarge disperse part of the surface tension which caninteract with the disperse part of the hotmelt. The higherthe work of adhesion the stronger is the adhesion of thehotmelt on the solid surface. Combination hotmelt/solid Work of adhesion [mJ/m] Sample 1/ABS 66,15 Sample 1 / alumina 54,72 Sample 1 / glass 73,89 Sample 1 / iron oxide on iron 52,96 Sample1/PA6.6 64,59 Sample 1/ PC 64,87 Sample 1/PE-LD 57,90 Sample 1/PE-HD 60,55 Sample 1/ PET 66,61 Sample 1/PMMA 69,17 Sample 1 / PP 58,13 Sample 1/ PS 66,30 Sample 1/ PVC 64,30 Sample1/ PTFE 46,52 Sample 1/PVC 64,30 Sample 1/ steel 57,95 Table 3: The work of adhesion for different combinations ofsample 1 at 140C/solid surfaces Summary The surface tension as well as the contact angle on PTFEof different hotmelts were estimated using the DropShape Analysis System in combination with the HighTemperature Dosing System. It could be shown, how thedisperse and the polar part of the surface tension and thework of adhesion are calculated and to which extentthese are relevant for the estimation of the wettability ofsolids. KRUSS GmbH|lBorsteler Chaussee Hamburg|Germany|www.kruss.de|

确定

还剩2页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《热熔胶中润湿和粘附功检测方案(接触角测量仪)》,该方案主要用于其他中润湿和粘附功检测,参考标准--,《热熔胶中润湿和粘附功检测方案(接触角测量仪)》用到的仪器有KRUSS DSA100接触角测量仪

相关方案

更多

该厂商其他方案

更多