方案详情

文

超声法来进行粒度检测是一门全新的技术,本文介绍了超声检测粒度的原理,以及在结晶系统中进行实时检测的无比的优越性,最后对测试结果做简单的分析。

方案详情

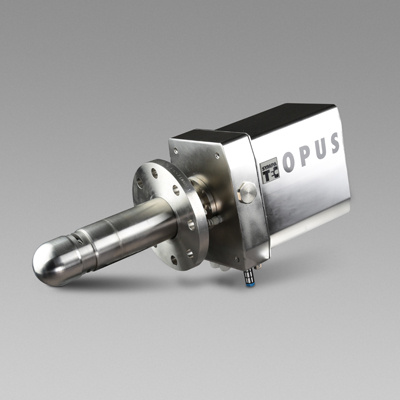

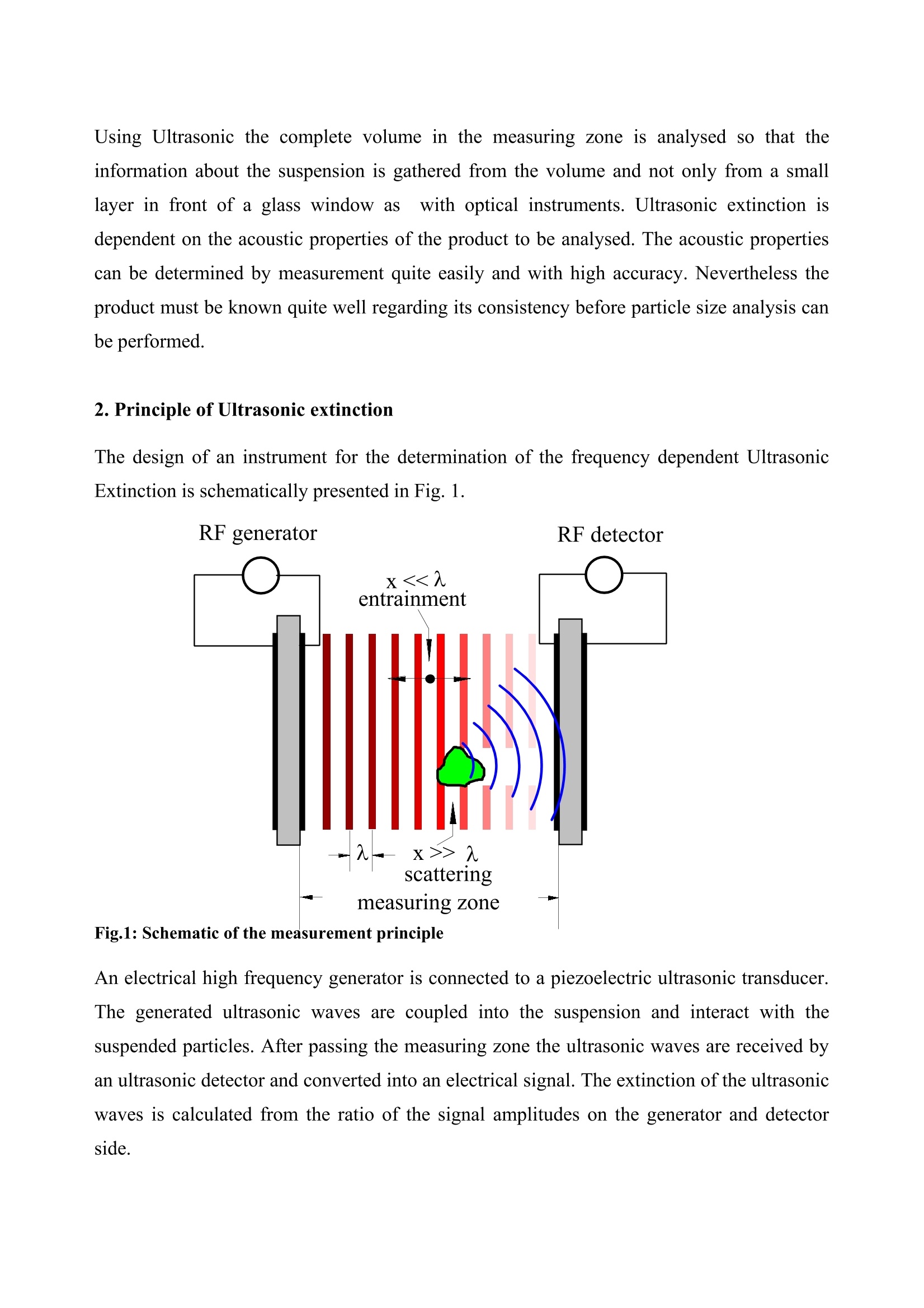

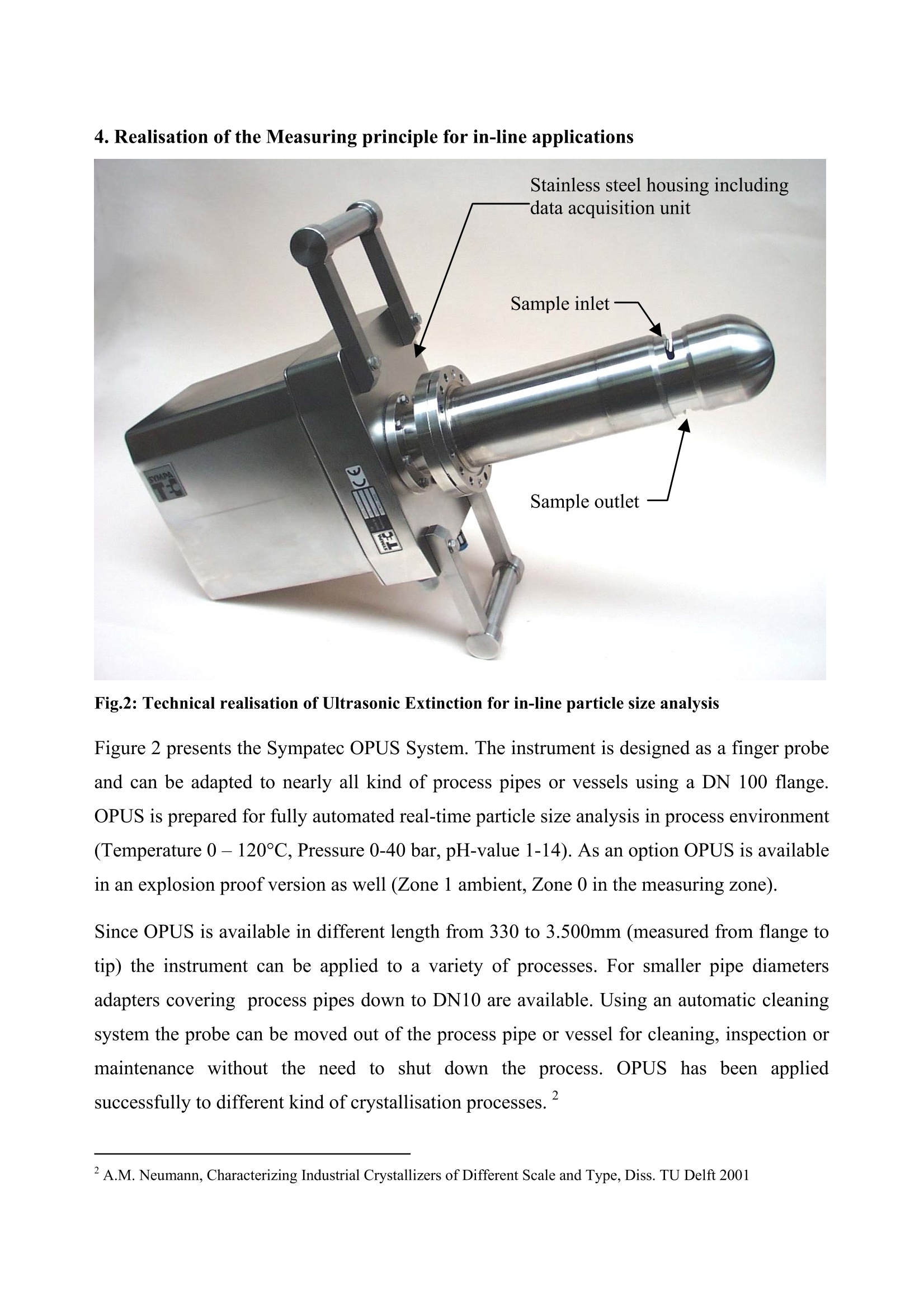

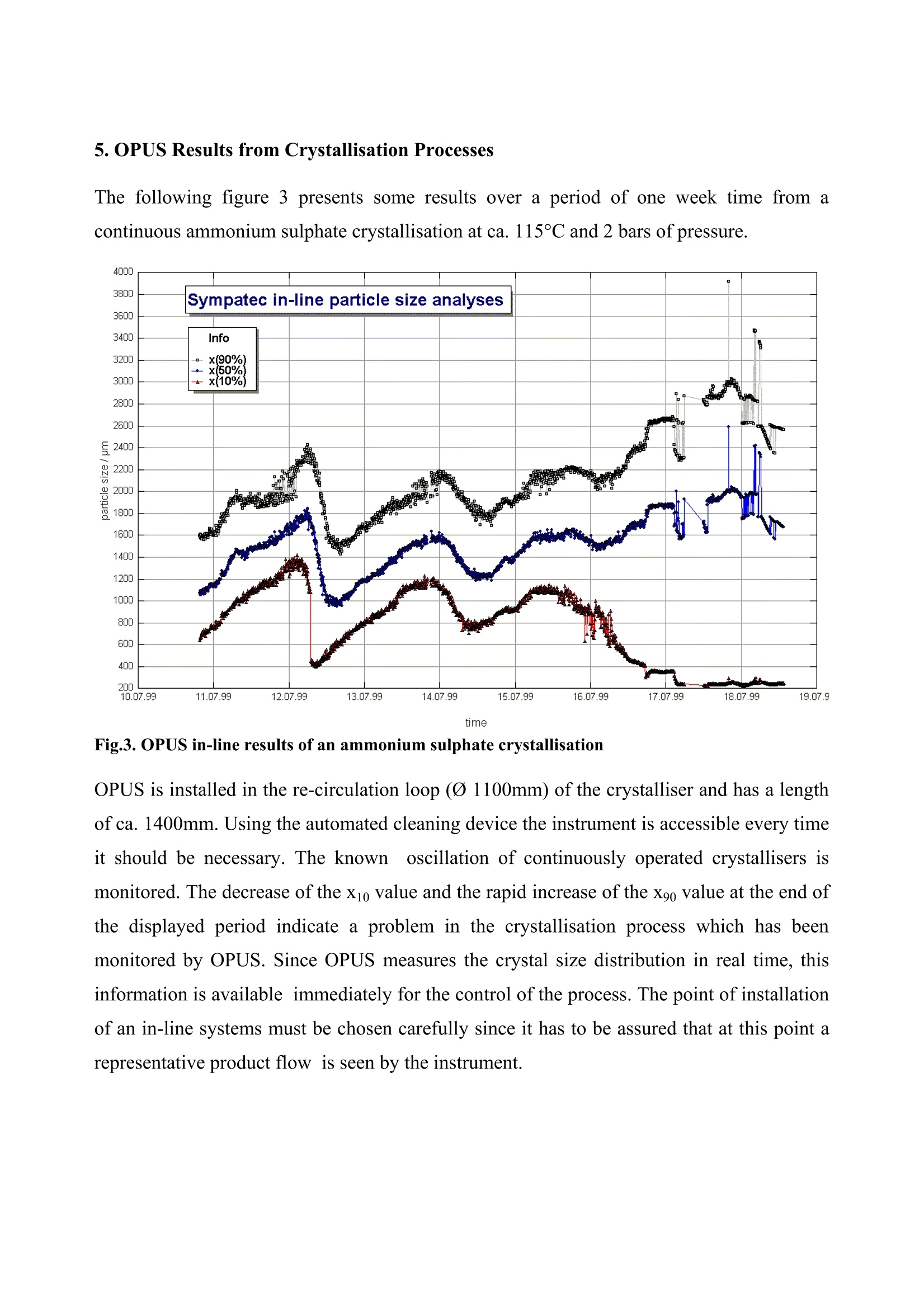

In-line Crystal Size Distribution analysis in industrialcrystallisation processes by Ultrasonic Extinction Dipl.-Ing. Axel Pankewitz, Dipl.-Ing. Helmut Geers Sympatec GmbH, System-Partikel-Technik, Clausthal-Zellerfeld, Germanyapankewitz@sympatec.com,hgeers@sympatec.com Abstract Ultrasonic Extinction is a relatively young method for the determination of particle (crystal)size distributions in high concentrated suspensions and allows the design of ruggedinstruments ideal for process application. After the description of technology and technicalrealisation, results of a successful installation will be presented to show that UltrasonicExtinction is proven technology for continuous and batch crystallisation processes. 1. Introduction In the last few years in-line particle size analysis has continued to reach more and moreimportance since this information is required for control and optimisation of chemicalprocess (e.g. crystallisation) Since a few years sensors based on Ultrasonic Extinction have beenapplied for in-lineparticle size analysis. As primary measurement information the frequency dependentUltrasonic Extinction which can be converted by a mathematical algorithm into a particlesize distribution, is used. Based on Ultrasonic Extinction very robust sensors can be build, which also can cope withtypical process pressures and temperatures. The use of Ultrasonic Extinction offers a varietyof advantages compared to optical principles. The analysis can be carried out in opaquesuspensions at high concentrations (typically up to 70% by volume.) The measured particlesize distributions are only affected very little by the concentration, which may vary in a widerange. Contamination on the sensor components does not influence the results. Using Ultrasonic the complete volume in the measuring zone is analysed so that theinformation about the suspension is gathered from the volume and not only from a smalllayer in front of a glass window as with optical instruments. Ultrasonic extinction isdependent on the acoustic properties of the product to be analysed. The acoustic propertiescan be determined by measurement quite easily and with high accuracy. Nevertheless theproduct must be known quite well regarding its consistency before particle size analysis canbe performed. 2. Principle of Ultrasonic extinction The design of an instrument for the determination of the frequency dependent UltrasonicExtinction is schematically presented in Fig. 1. Fig.1: Schematic of the measurement principle An electrical high frequency generator is connected to a piezoelectric ultrasonic transducer.The generated ultrasonic waves are coupled into the suspension and interact with thesuspended particles. After passing the measuring zone the ultrasonic waves are received byan ultrasonic detector and converted into an electrical signal. The extinction of the ultrasonicwaves is calculated from the ratio of the signal amplitudes on the generator and detectorside. 3. Description of Ultrasonic Extinction of poly-disperse systems The Ultrasonic Extinction of a suspension of mono-disperse particles can be described bythe Lambert-Beer law according to Riebel. -ln =Al·Cpr·K(f,x)Equation 1o)f. The Extinction -In(I/Io) at a give frequency f is linear dependent on the thickness of thesuspension layer Al , the projection area-concentration CpF and the extinction coefficient K. In a poly-disperse system the extinction of single particles overlays: The integral in equation 2 can be substituted by a sum as a first approach: If now extinction measurements are performed at various frequencies, this results in a linearequation system: Equation 4 This equation system is numerically unstable and must be solved by suitable algorithms. ( R i ebel U., D i e Grundlage der PartikelgroBenanalyse mittels Ultraschallspektrometrie, Diss. Karlsruhe 1998 ) 4. Realisation of the Measuring principle for in-line applications Fig.2: Technical realisation of Ultrasonic Extinction for in-line particle size analysis Figure 2 presents the Sympatec OPUS System. The instrument is designed as a finger probeand can be adapted to nearly all kind of process pipes or vessels using a DN 100 flange.OPUS is prepared for fully automated real-time particle size analysis in process environment(Temperature 0- 120℃, Pressure 0-40 bar, pH-value 1-14). As an option OPUS is availablein an explosion proof version as well (Zone1 ambient, Zone 0 in the measuring zone). Since OPUS is available in different length from 330 to 3.500mm (measured from flange totip) the instrument can be applied to a variety of processes. For smaller pipe diametersadapters covering process pipes down to DN10 are available. Using an automatic cleaningsystem the probe can be moved out of the process pipe or vessel for cleaning, inspection ormaintenance without the need to shut down the process. (OPUS has been appliedsuccessfully to different kind of crystallisation processes. ( A.M. Neumann, Characterizing Indus t rial Crys t allizers of Different Scale and Type, Diss. TU D e lft 2001 ) 5. OPUS Results from Crystallisation Processes The following figure 3 presents some results over a period of one week time from acontinuous ammonium sulphate crystallisation at ca. 115°℃ and 2 bars of pressure. Fig.3. OPUS in-line results of an ammonium sulphate crystallisation OPUS is installed in the re-circulation loop (O 1100mm) of the crystalliser and has a lengthof ca. 1400mm. Using the automated cleaning device the instrument is accessible every timeit should be necessary. The knownoscillation of continuously operated crystallisers ismonitored. The decrease of the X1o value and the rapid increase of the X90 value at the end ofthe displayed period indicate a problem in the crystallisation process which has beenmonitored by OPUS. Since OPUS measures the crystal size distribution in real time, thisinformation is available immediately for the control of the process. The point of installationof an in-line systems must be chosen carefully since it has to be assured that at this point arepresentative product flow is seen by the instrument. 6. Conclusion and Outlook The presented ultrasonic based Sympatec OPUS system is best suited for in-line particle sizeanalysis of crystallisation processes. Because of the ultrasonic specific properties the sensoris very robust and engineered to withstand the typical temperature and pressure in acrystallisation process without any problem. The finger probe design also makes installationeasy for existing crystallisers. Since the measurement is carried out at original solid concentrations, dilution of the crystalsuspension is not required. Several installations show that OPUS is proved in the field of industrial crystallisation andprocesses can be controlled in real time. In the future it is to be expected that in-line particle size analysis will provide the necessaryinformation for the modelling of industrial crystallisation processes. Based on improvedmodels automatic process controlwill be possible which will lead to a better quality of theuser’s product.

确定

还剩4页未读,是否继续阅读?

德国新帕泰克有限公司苏州代表处为您提供《湿法在线应用的原理和实测结果说明(英文)》,该方案主要用于其他中--检测,参考标准--,《湿法在线应用的原理和实测结果说明(英文)》用到的仪器有德国工业在线湿法粒度仪

相关方案

更多