Leica Cleanliness Expert 是一个定量的品质控制系统它帮助监察在制造过程中元件的品质.

它被设计为测量给显微机械和引擎的洁净流体的污染和可以在所有应用中使用那里要为圆形颗粒基层做颗粒分类和特征分析

测量可以与 ISO 16232 和 VDA 19 标准符合.

方案详情

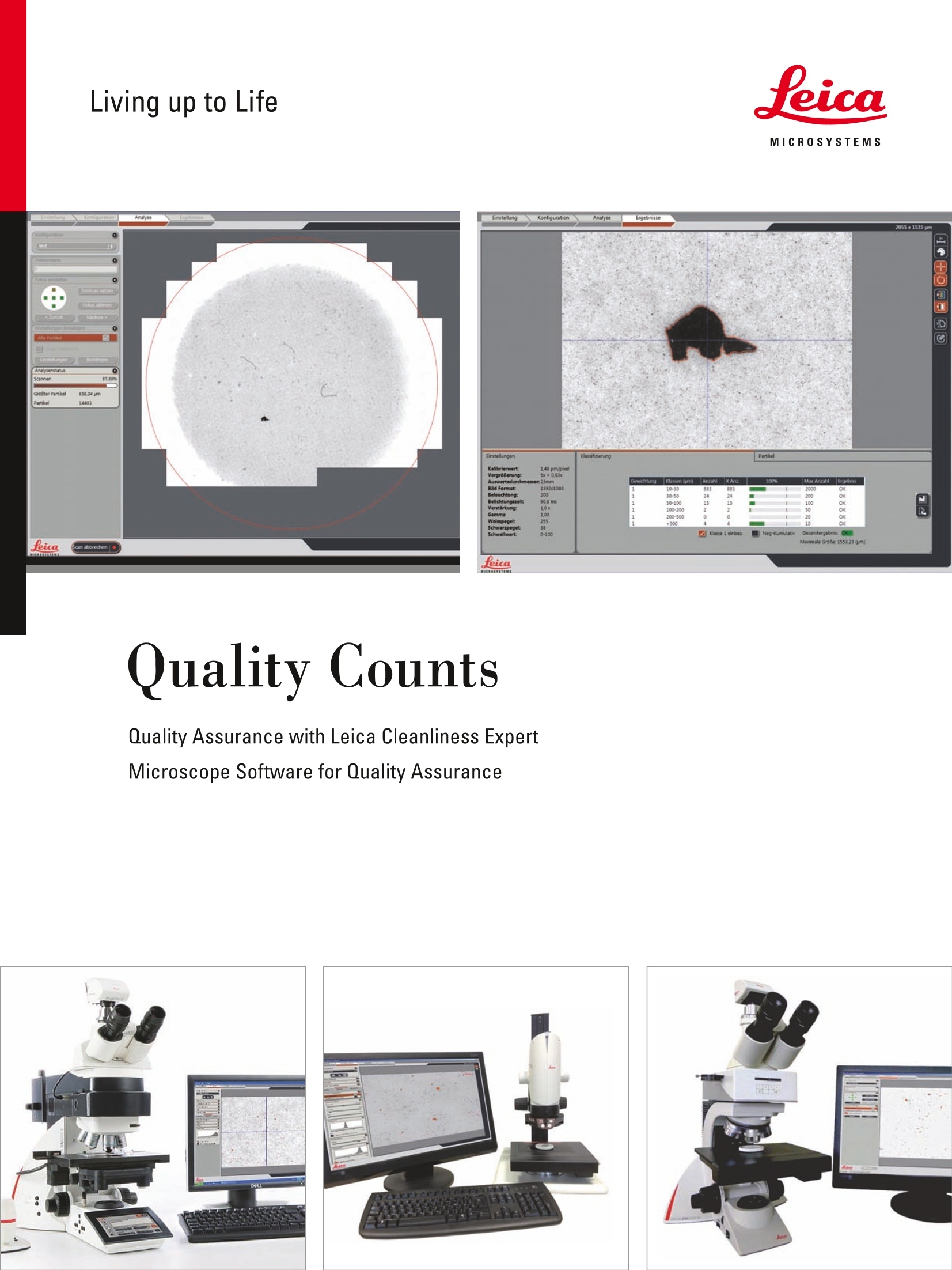

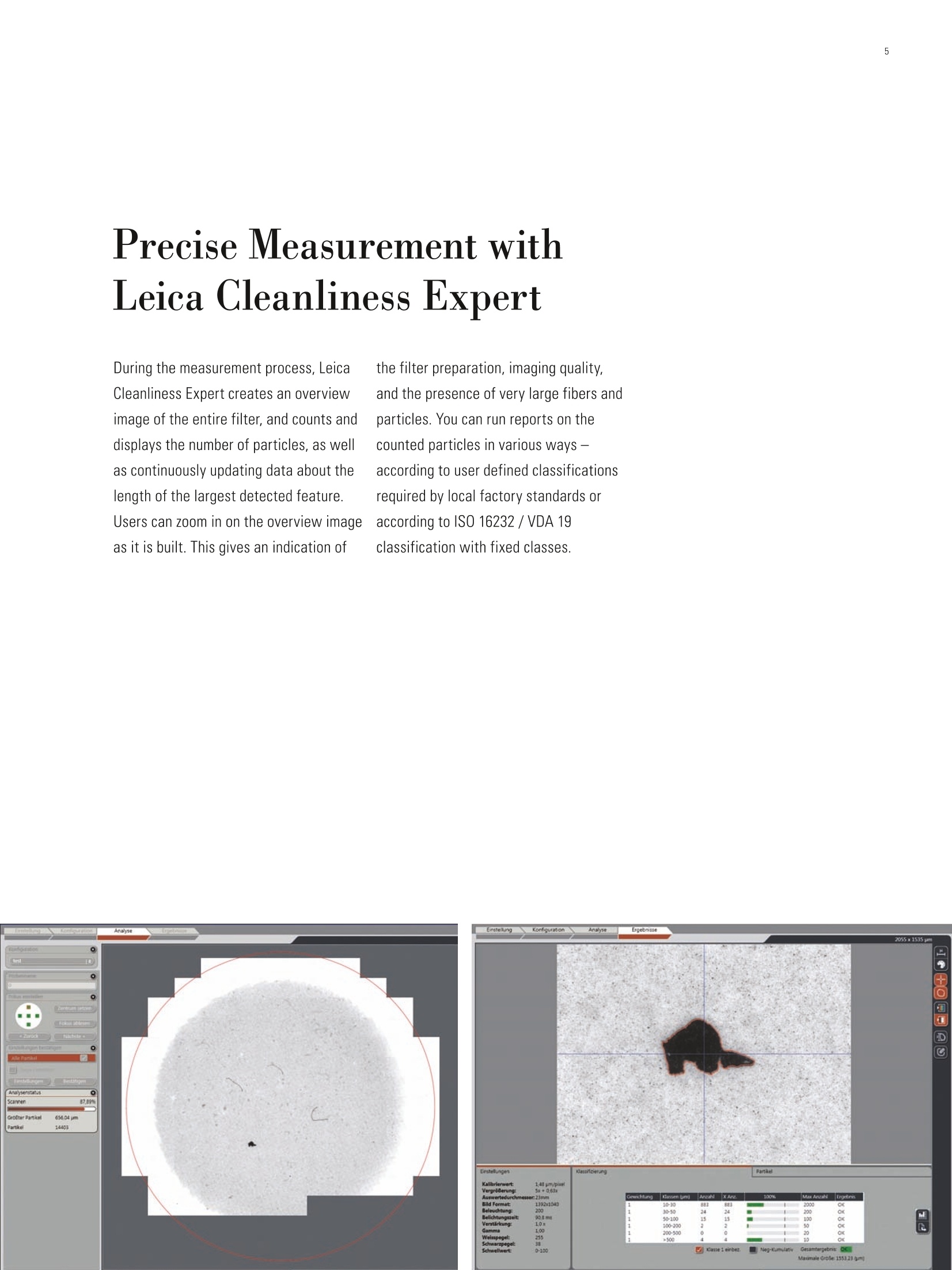

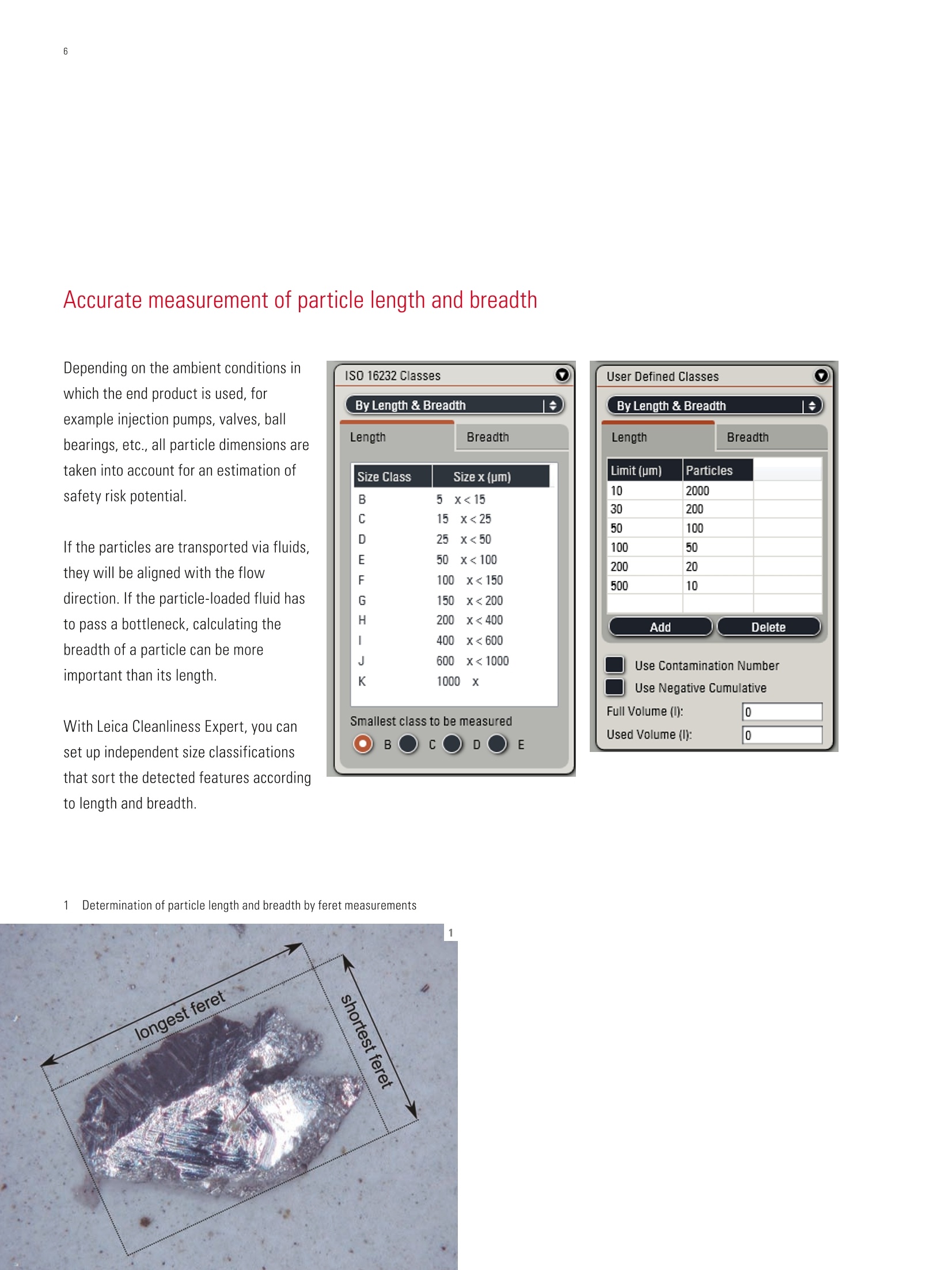

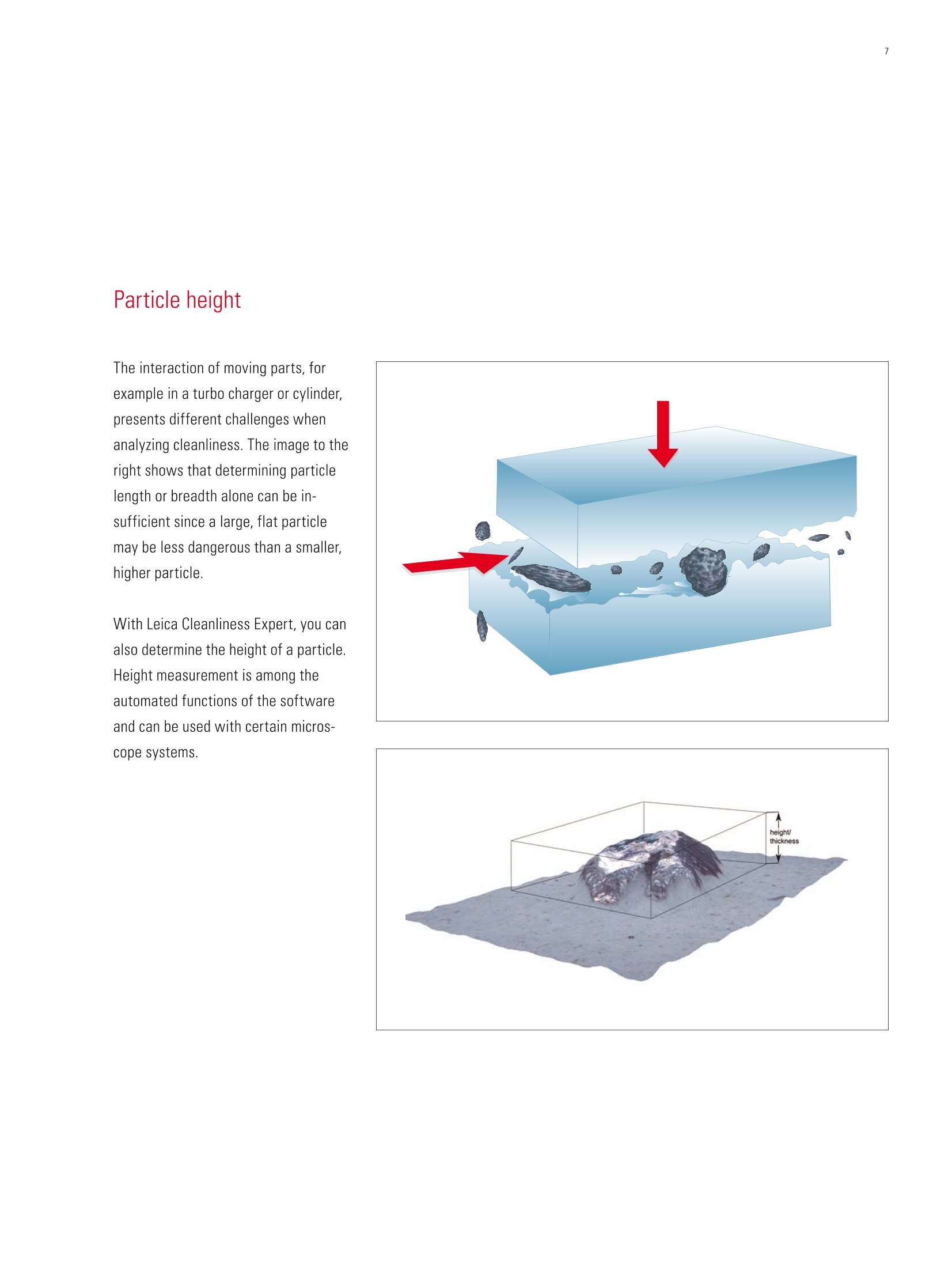

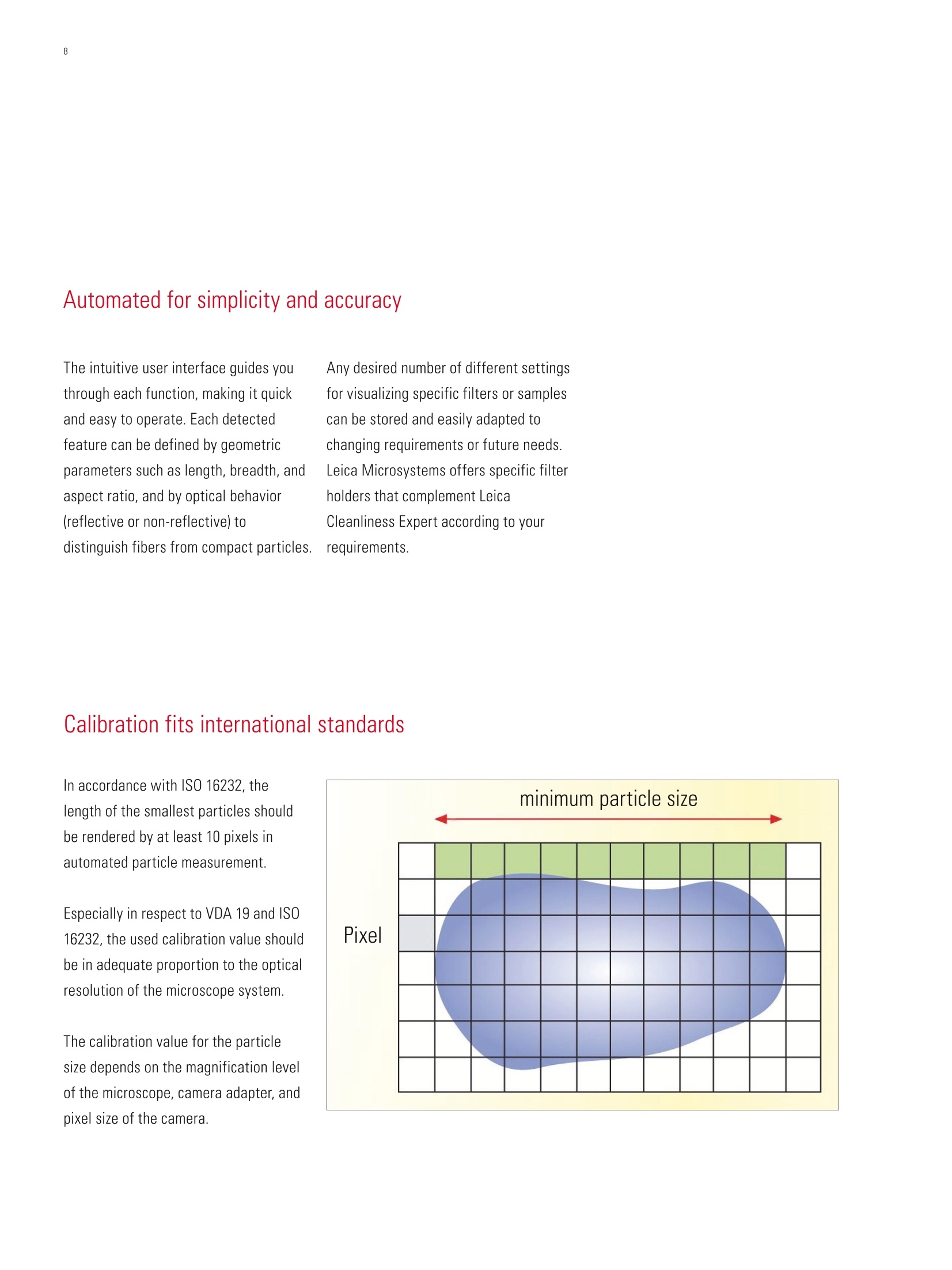

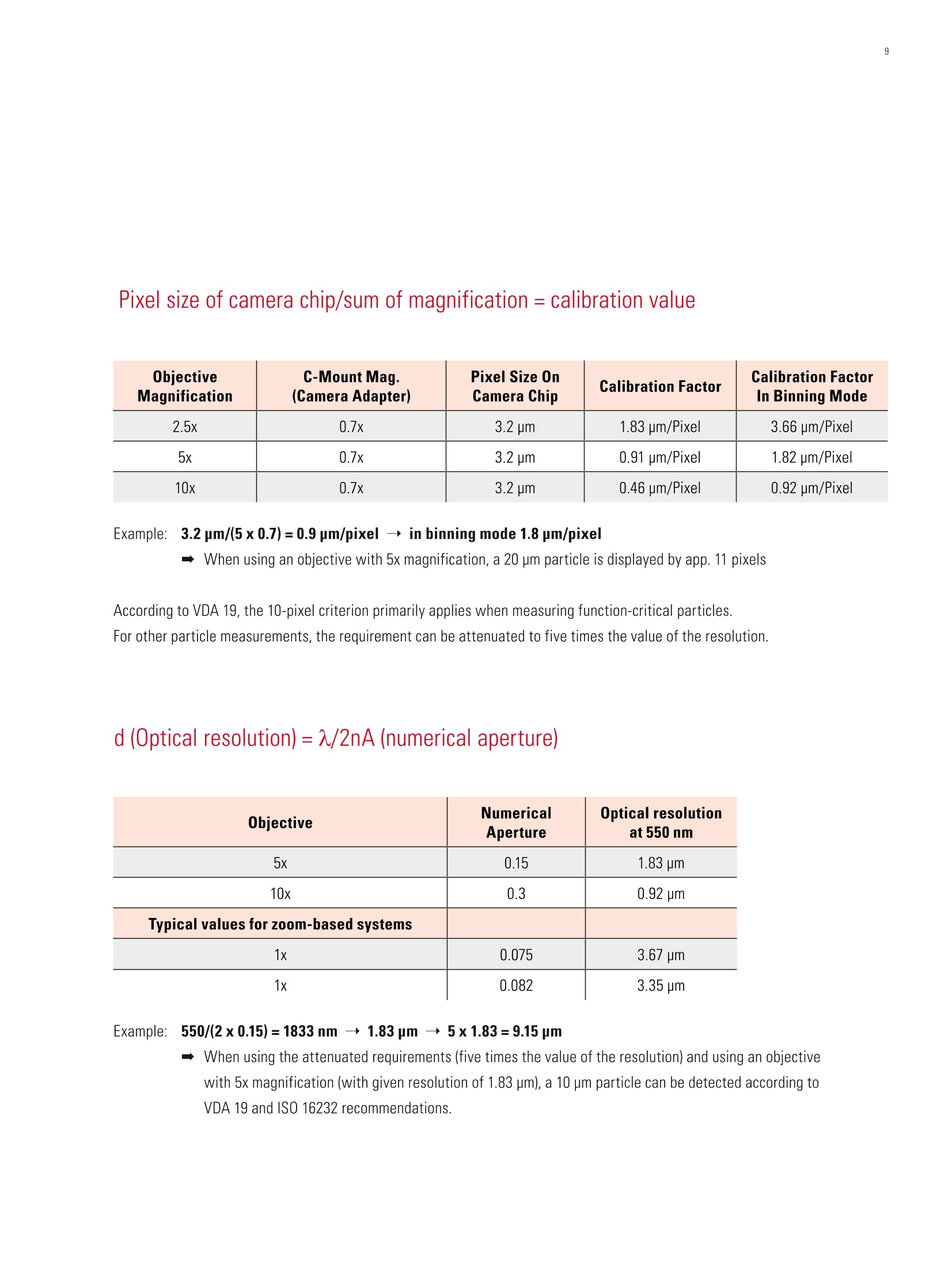

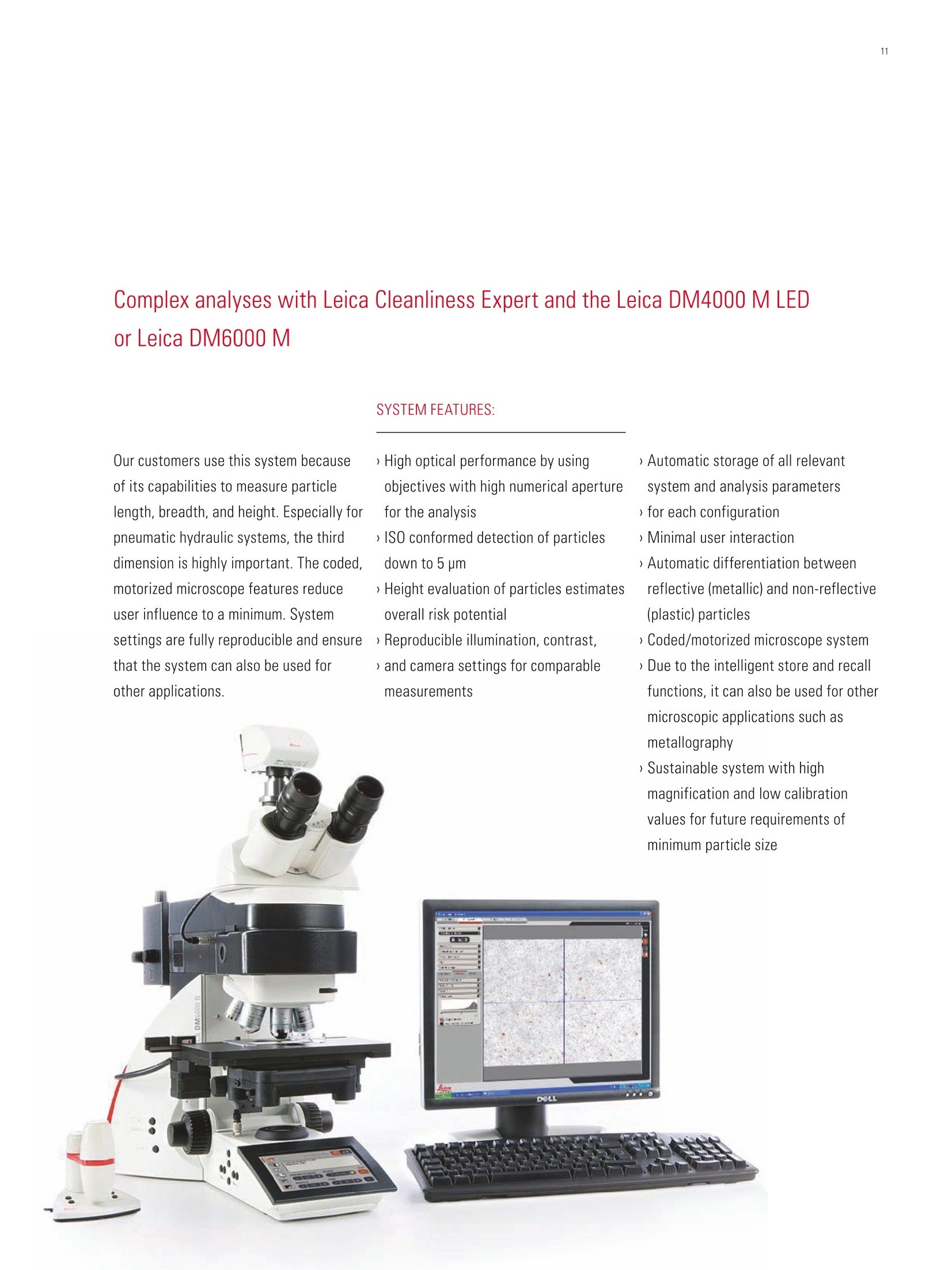

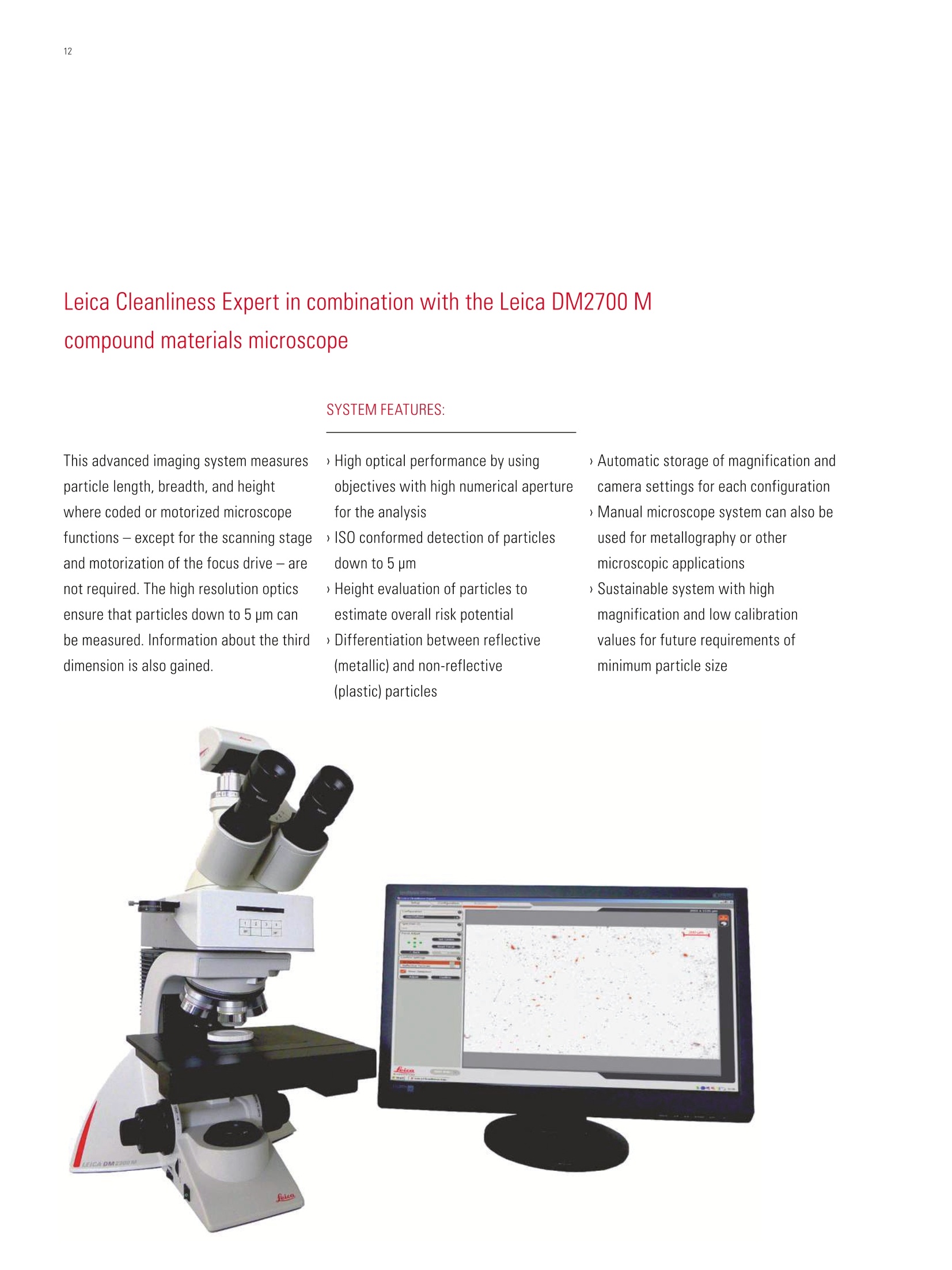

Living up to LifeMICROSYSTEM S 5 Order no.: English ??????VII/13/???/????.Copyright C by Leica Microsystems CMS GmbH,Wetzlar, Germany, 2013. Subject to modifications.LEICA and the Leica Logo are registeredtrademarks of Leica Microsystems IR GmbH. Ouality Counts Quality Assurance with Leica Cleanliness ExpertMicroscope Software for Quality Assurance 一一 OM Quality Counts Manufacturers need to assess thecleanliness and integrity of componentsand liquids to ensure a safer, defect-freeend product. Microscopic analysis ofcleanliness is an essential workflow stepin modern manufacturing processes,especially when complex systems asgearboxes, turbines or engines areassembled using various componentsfrom multiple suppliers. The quality,durability, and life cycle of a final productCtdepend on the quality and characteristicsof the material, fitting tolerances,and overall cleanliness of a surfaceor particle load. A defect in a singlecomponent can lead to the breakdownof the entire end product. Leica Cleanliness Expert microscopesoftware is a quantitative qualityassurance system that allows you tomonitor, analyze, and documentcomponent quality during themanufacturing process and before acomponent is integrated with an endproduct. Leica Cleanliness Expert is idealfor all applications involving particleclassification and characterization oncircular shaped substrates. The softwaretypically supports users in theautomotive, galvanic, and aviationsectors, as well as the pharmaceuticalindustry. It is particularly useful toconduct analyses when hydraulic fluidsare concerned. Experience Creates Reliability As system components continuouslydecrease in size, we have adapted andimproved our cleanliness monitoringsystems and analytical softwarepackages in close collaboration withleading industry representatives toensure that wemeet your current and future needs.For instance, the publication of VDA 19in 2002 and the release of ISO 16232in 2007 ignited discussion among ourautomotive industry customers aboutthe new requirements and improvementpossibilities for technical cleanlinessanalysis. Leica Microsystems activelyparticipat in this discourse about therevision of VDA 19 and draft of DIN 51455:Liquid mineral oils - determination ofparticle number and particle size in oils. As a provider of inspection systems forcleanliness analysis, Leica Microsystemsoffers the right solutions. Users benefitfrom the reliable results. You will receiveinformation about: ) Number of particles -> overall degreeof contamination ) Particle size (length, breadth andheight)-> damage potential of asingle particle s Material of the particles (reflective ornon-reflective, therefore metallic orplastic)-> general damage potential ofthe particle load as well as damagepotential of a single particle Differentiation between particles andfibers > damage potential of a singleparticle and source of contamination Depending on the analyzed product theimportance of the above mentionedpoints may vary. This is why LeicaCleanliness Expert offers flexibleconfiguration and a number of local,national,and international standardssuch as ISO 16232, VDA 19, and ISO 4406according to which the analysis can beperformed. Precise Measurement withLeica Cleanliness Expert During the measurement process, LeicaCleanliness Expert creates an overviewimage of the entire filter, and counts anddisplays the number of particles, as wellas continuously updating data about thelength of the largest detected feature.Users can zoom in on the overview imageas it is built. This gives an indication of the filter preparation, imaging quality,and the presence of very large fibers andparticles. You can run reports on thecounted particles in various ways -according to user defined classificationsrequired by local factory standards oraccording to ISO 16232 / VDA 19classification with fixed classes. Accurate measurement of particle length and breadth Depending on the ambient conditions inwhich the end product is used, forexample injection pumps, valves, ballbearings, etc., all particle dimensions aretaken into account for an estimation ofsafety risk potential. If the particles are transported via fluids,they will be aligned with the flowdirection. If the particle-loaded fluid hasto pass a bottleneck, calculating thebreadth of a particle can be moreimportant than its length. Limit (pm) Particles 10 2000 30 200 50 100 100 50 200 20 500 10 With Leica Cleanliness Expert, you canset up independent size classificationsthat sort the detected features accordingto length and breadth. 1 Determination of particle length and breadth by feret measurements The interaction of moving parts, forexample in a turbo charger or cylinder,presents different challenges whenanalyzing cleanliness. The image to theright shows that determining particlelength or breadth alone can be in-sufficient since a large, flat particlemay be less dangerous than a smaller,higher particle. With Leica Cleanliness Expert, you canalso determine the height of a particle.Height measurement is among theautomated functions of the softwareand can be used with certain micros-cope systems. Automated for simplicity and accuracy The intuitive user interface guides youthrough each function, making it quickand easy to operate. Each detectedfeature can be defined by geometricparameters such as length, breadth, andaspect ratio,and by optical behavior(reflective or non-reflective) to Any desired number of different settingsfor visualizing specific filters or samplescan be stored and easily adapted tochanging requirements or future needs.Leica Microsystems offers specific filterholders that complement LeicaCleanliness Expert according to yourrequirements. In accordance with ISO 16232, thelength of the smallest particles shouldbe rendered by at least 10 pixels inautomated particle measurement. Especially in respect to VDA 19 and ISO16232, the used calibration value shouldbe in adequate proportion to the opticalresolution of the microscope system. The calibration value for the particlesize depends on the magnification levelof the microscope, camera adapter, andpixel size of the camera. Pixel size of camera chip/sum of magnification = calibration value ObjectiveMagnification C-Mount Mag.(Camera Adapter) Pixel Size OnCamera Chip Calibration Factor Calibration FactorIn Binning Mode 2.5x 0.7x 3.2 um 1.83 um/Pixel 3.66 pm/Pixel 5x 0.7x 3.2 um 0.91 pm/Pixel 1.82 pm/Pixel 10x 0.7x 3.2 um 0.46 um/Pixel 0.92 um/Pixel Example:3.2 pm/(5x0.7)=0.9um/pixel →in binning mode 1.8 um/pixel When using an objective with 5x magnification, a 20 pm particle is displayed by app. 11 pixels According to VDA 19, the 10-pixel criterion primarily applies when measuring function-critical particles. For other particle measurements, the requirement can be attenuated to five times the value of the resolution. d(Optical resolution)= 入/2nA (numerical aperture) Objective NumericalAperture Optical resolutionat 550 nm 5x 0.15 1.83 pm 10x 0.3 0.92 um Typical values for zoom-based systems 1x 0.075 3.67 um 1x 0.082 3.35 pm Example:!550/(2x0.15)=1833nm→1.83pm→5x1.83=9.15 pm When using the attenuated requirements (five times the value of the resolution) and using an objectivewith 5x magnification (with given resolution of 1.83 pm), a 10 pm particle can be detected according toVDA 19 and ISO 16232 recommendations. Choose the System that Meetsyour Requirements The flexibility of Leica CleanlinessExpert mirrors the diversity of modernapplications and needs. Differentrequirements concerning particle size,shape, type,classification, normalization,and the used standard (local, nationalor international) can be covered by theanalysis system. Leica Microsystems offers differentsystems depending on user-specificneeds. Complex analyses with Leica Cleanliness Expert and the Leica DM4000 M LEDor Leica DM6000 M Our customers use this system becauseof its capabilities to measure particlelength, breadth, and height. Especially forpneumatic hydraulic systems, the thirddimension is highly important. The coded,motorized microscope features reduceuser influence to a minimum. Systemsettings are fully reproducible and ensurethat the system can also be used forother applications. >High optical performance by usingobjectives with high numerical aperture for the analysis ISO conformed detection of particles down to 5 um) Height evaluation of particles estimatesoverall risk potential) Reproducible illumination, contrast, and camera settings for comparablemeasurements >Automatic storage of all relevantsystem and analysis parameters for each configuration )Minimal user interaction ) Automatic differentiation between reflective (metallic) and non-reflective(plastic) particles Coded/motorized microscope system Due to the intelligent store and recallfunctions, it can also be used for othermicroscopic applications such as ) Sustainable system with highmagnification and low calibrationvalues for future requirements ofminimum particle size Leica Cleanliness Expert in combination with the Leica DM2700 Mcompound materials microscope This advanced imaging system measuresparticle length, breadth, and heightwhere coded or motorized microscopefunctions - except for the scanning stageand motorization of the focus drive -arenot required. The high resolution opticsensure that particles down to 5 um canbe measured. Information about the thirddimension is also gained. > High optical performance by usingobjectives with high numerical aperturefor the analysis) ISO conformed detection of particlesdown to 5 pm) Height evaluation of particles toestimate overall risk potential) Differentiation between reflective(metallic) and non-reflective (plastic) particles ) Automatic storage of magnification andcamera settings for each configuration; Manual microscope system can also beused for metallography or othermicroscopic applicationsSustainable system with highmagnification and low calibrationvalues for future requirements ofminimum particle size An ideal solution for detecting large particles: the Leica DMS300 Cleanliness Expertor Leica DMS1000 Cleanliness Expert The Leica DMS-based Cleanliness Expertsystems are ideal for the measurementof particle length and breadth as well asfor differentiating between reflectiveand non-reflective particles. The compactdigital microscope systems are availablein two configurations: 1.) manual zoom(Leica DMS300 Cleanliness Expert), 2.) coded version (Leica DMS1000 Cleanliness Expert).Click stop positions can be activatedin both versions. ) High optical performanceyISO conformed detection of particles down to 20 um ) Differentiation between reflective(metallic) and non-reflective (plastic)particles > Automatic storage of magnification andcamera settings for each configuration Compact design >No parallax error as on stereo microscopes, due to single beam pathyManual or coded optic carrier Functional, reliable, flexible - Leica Cleanliness Expert in a nutshell FUNDAMENTAL FUNCTIONALITIES RELIABILITY FLEXIBILITY ; User-friendly graphical user interface > Detection in live image > Re-positioning of detected particles Guided analysis workflow ) Scaling in live image after scan y Automatic differentiation between > Auto tracing of particles and fibers Re-classification possibility reflective (metallic) and non-reflective across image boundaries -> no Editing function (plastic) particles maximum size limit for particles to ) Editable report format ) Length measurement be measured ) Multiple measurement parameters can Breadth measurement Zoom function during scanning process be added to the report Height measurement Size of largest detected particle is ) Supported standards: user-defined, displayed and updated during scanning ISO 16232 (VDA 19),ISO 4406, process USP 788, etc. ) Number of detected particles is dis- ; Differentiation between particles played and updated during scanning and fibers process Auto leveling function for uneven ) Different user levels ) All hardware settings (microscope and camera) are automatically stored All measurement parameters and their changes are automatically stored Unauthorized changes of the configura- tion settings are recorded and reported > Reclassification and editing of theresults are automatically documented ) Traceability by auto logging function The statement by Ernst Leitz in 1907, "With the User, For the User," describes the fruitful collaboration with end users and driving force ofinnovation at Leica Microsystems. We have developed five brand values to live up to this tradition: Pioneering, High-end Quality, Team Spirit,Dedication to Science, and Continuous Improvement. For us, living up to these values means: Living up to Life. Leica Microsystems operates globally in three divisions, where we rank Leica Microsystems- an international company with a strong networkwith the market leaders. of worldwide customer services: LIFE SCIENCE DIVISION The Leica Microsystems Life Science Division supports the imagingneeds of the scientific community with advanced innovation andtechnical expertise for the visualization, measurement, and analysisof microstructures. Our strong focus on understanding scientificapplications puts Leica Microsystems’ customers at the leading edgeof science. INDUSTRY DIVISION The Leica Microsystems Industry Division’s focus is to supportcustomers’ pursuit of the highest quality end result. Leica Microsystemsprovide the best and most innovative imaging systems to see,measure,and analyze the microstructures in routine and research industrialapplications, materials science, quality control, forensic science inves-tigation, and educational applications. MEDICAL DIVISION The Leica Microsystems Medical Division's focus is to partner withand support surgeons and their care of patients with the highest-quality,most innovative surgical microscope technology today and into thetuture. Activeworldwide Tel. Fax Australia· North Ryde +61 288703500 298781055 Austria · Vienna +43 148680500 1 486 805030 Belgium· Diegem +32 27909850 27909868 Canada·Concord/Ontario +1 8002480123 8474050164 Denmark· Ballerup +45 44540101 44540111 France·Nanterre Cedex +33 811000664 156052323 Germany·Wetzlar +49 6441 29 40 00 6441294155 Italy·Milan +39 02574861 0257403392 Japan· Tokyo +81 354212800 354212896 Korea · Seoul +82 25146543 25146548 Netherlands· Rijswijk +31 704132100 704132109 People’s Rep. of China· Hong Kong +852 25646699 25644163 ·Shanghai +86 2163876606 2163876698 Portugal· Lisbon +351 213889112 213854668 Singapore +65 67797823 67730628 Spain·Barcelona +34 934949530 934949532 Sweden · Kista +46 86254545 86254510 Switzerland· Heerbrugg +41 71 726 3434 717263444 United Kingdom· Milton Keynes +44 8002982344 1908246312 USA · Buffalo Grove/lllinois +1 8002480123 8474050164

确定

还剩13页未读,是否继续阅读?

徕卡显微系统(上海)贸易有限公司为您提供《车身及附件中清洁度分析检测方案(立体显微镜)》,该方案主要用于车身及附件中理化分析检测,参考标准--,《车身及附件中清洁度分析检测方案(立体显微镜)》用到的仪器有全自动清洁度分析系统 Leica Cleanliness Expert

推荐专场

相关方案

更多