方案详情

文

Gel permeation chromatography (GPC) is a highly effective method for the removal

of high molecular weight interferences such as lipids from a fatty food prior to

analysis for the compounds of interest. GPC has been used to clean up fatty foods

contaminated with plasticizers and other plastics additives.

方案详情

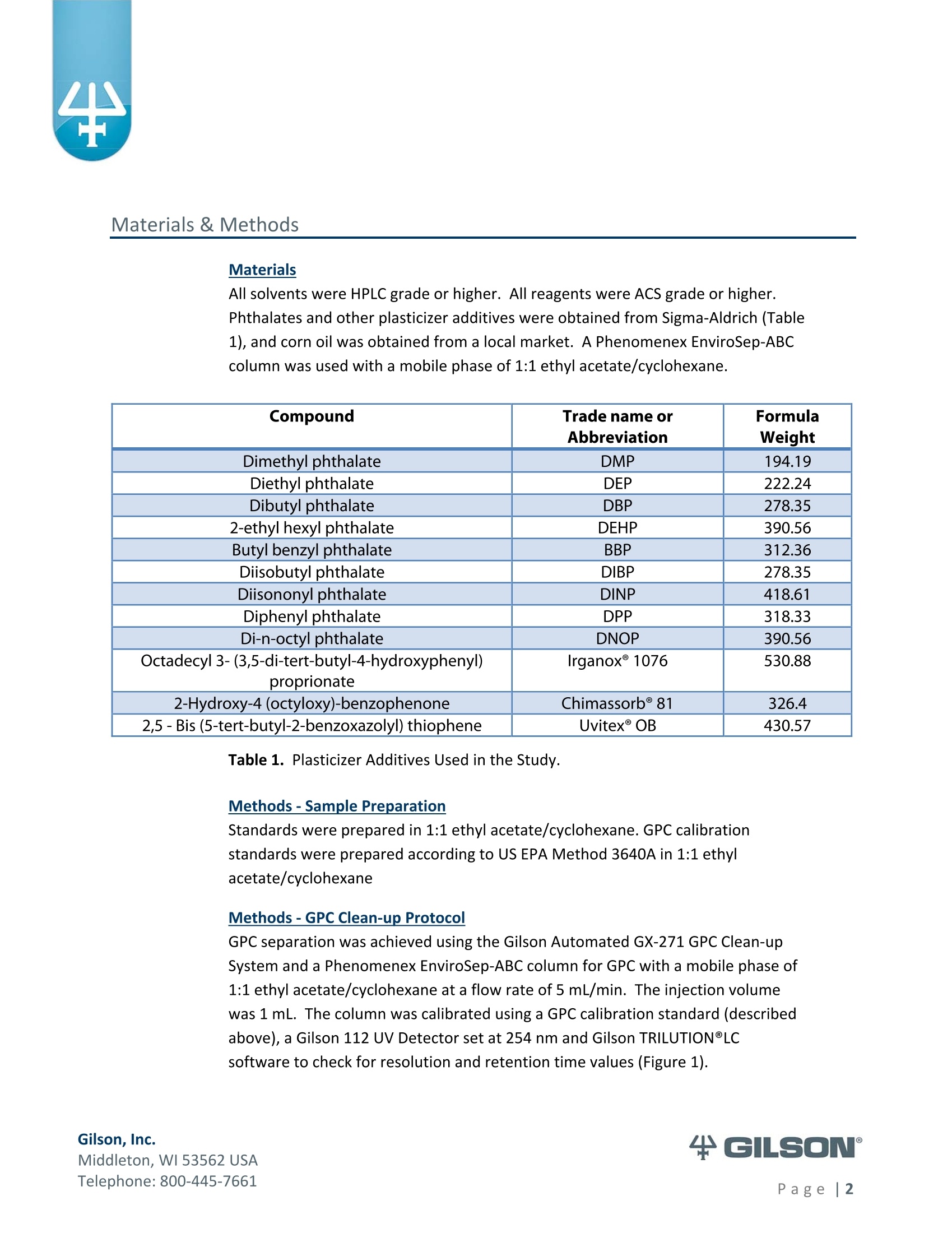

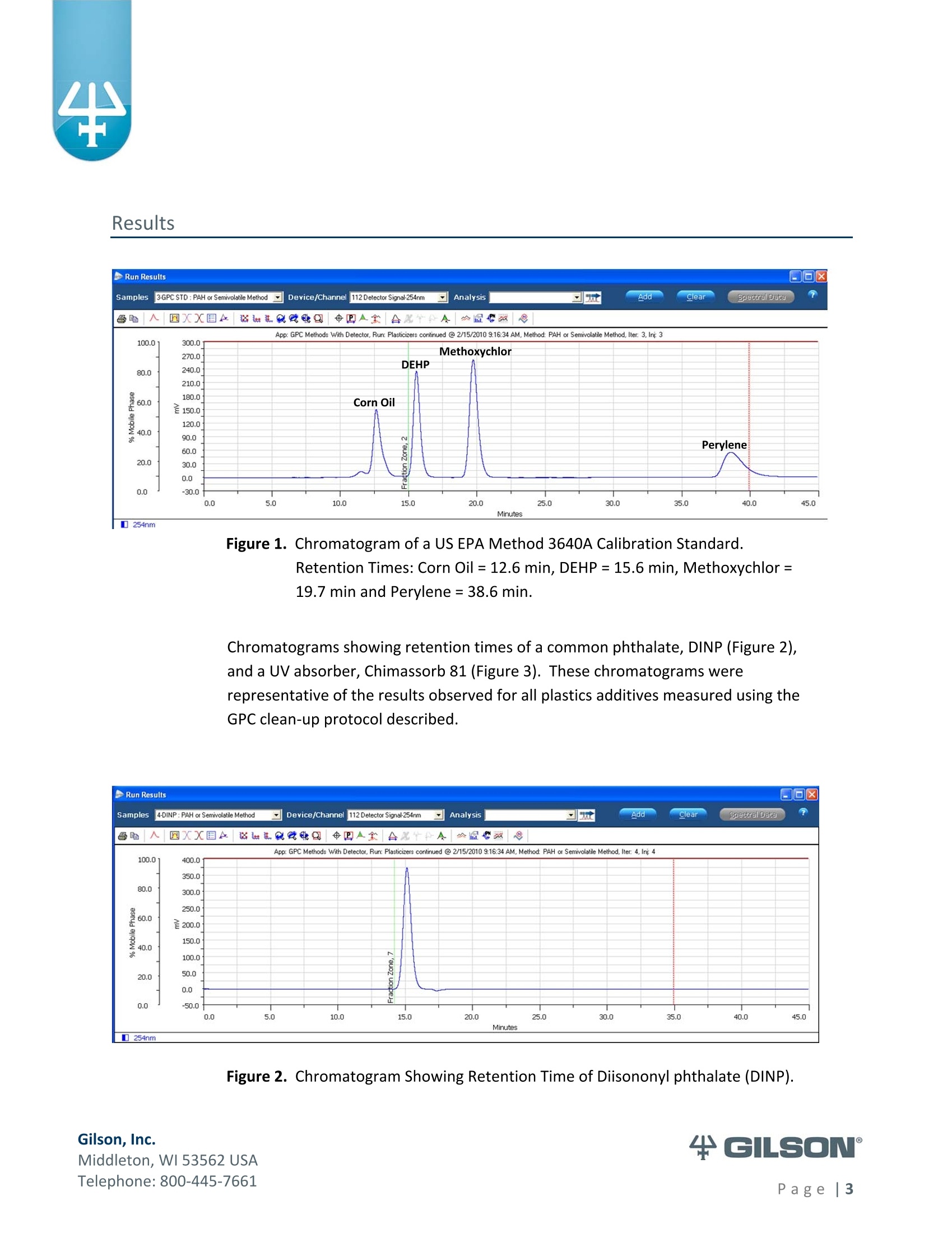

Materials & Methods Summarv Clean-up of Plastics Additives from Edible OilsUsing Gel Permeation Chromatography (GPC) Application Note FB0413 Keywords Gel Permeation Chromatography, GX-271 GPC Clean-Up System, automated sampleclean-up, plastics additives, phthalates, separation,high molecular weightinterferences Introduction Plastics are ubiquitous in our society and are extensively used in a large variety ofpackaged foods. A variety of chemicals that enhance the physical quality of plasticsare often added as well. Some commonly used additives include plasticizers (suchas phthalates) to improve flexibility, UV filters for protection from sunlight,brightening agents, coloring agents, and preservatives. Enhanced by a number ofenvironmental factors, some of these additives may migrate into food products thathave been packaged using plastics. There is currently a great deal of interest inmeasuring the migration of these compounds into food products, as considerableuncertainty exists regarding the human health risks associated with exposure tosuch compounds. Gel permeation chromatography (GPC) is a highly effective method for the removalof high molecular weight interferences such as lipids from a fatty food prior toanalysis for the compounds of interest. GPC has been used to clean up fatty foodscontaminated with plasticizers and other plastics additives. This note describes the use of GPC clean-upto separate a variety of plastics additives,such as phthalates, Chimassorb@ 81 (a UVabsorber and stabilizer),Irganox@ 1076 (anoptical brightener) and Uvitex OB (anantioxidant and thermal stabilizer) from arepresentative edible oil sample prior toanalysis. Middleton, WI 53562 USA Telephone: 800-445-7661 Materials All solvents were HPLC grade or higher. All reagents were ACS grade or higher.Phthalates and other plasticizer additives were obtained from Sigma-Aldrich (Table1), and corn oil was obtained from a local market. A Phenomenex EnviroSep-ABCcolumn was used with a mobile phase of 1:1 ethyl acetate/cyclohexane. Compound Trade name orAbbreviation Formula Weight Dimethyl phthalate DMP 194.19 Diethyl phthalate DEP 222.24 Dibutyl phthalate DBP 278.35 2-ethyl hexyl phthalate DEHP 390.56 Butyl benzyl phthalate BBP 312.36 Diisobutyl phthalate DIBP 278.35 Diisononyl phthalate DINP 418.61 Diphenyl phthalate DPP 318.33 Di-n-octyl phthalate DNOP 390.56 Octadecyl3-(3,5-di-tert-butyl-4-hydroxyphenyl)proprionate Irganox° 1076 530.88 2-Hydroxy-4(octyloxy)-benzophenone Chimassorb81 326.4 2,5-Bis (5-tert-butyl-2-benzoxazolyl) thiophene Uvitex°OB 430.57 Table 1. Plasticizer Additives Used in the Studv. Methods-Sample Preparation Standards were prepared in 1:1 ethyl acetate/cyclohexane. GPC calibrationstandards were prepared according to US EPA Method 3640A in 1:1 ethylacetate/cyclohexane Methods -GPC Clean-up Protocol GPC separation was achieved using the Gilson Automated GX-271 GPC Clean-upSystem and a Phenomenex EnviroSep-ABC column for GPC with a mobile phase of1:1 ethyl acetate/cyclohexane at a flow rate of 5 mL/min. The injection volumewas 1 mL. The column was calibrated using a GPC calibration standard (describedabove), a Gilson 112 UV Detector set at 254 nm and Gilson TRILUTIONLCsoftware to check for resolution and retention time values (Figure 1). ( T el ep h o ne: 8 0 0 -4 45 - 7 6 61 ) Results 254nm Figure 1. Chromatogram of a US EPA Method 3640A Calibration Standard.Retention Times: Corn Oil=12.6 min, DEHP=15.6 min, Methoxychlor=19.7 min and Perylene= 38.6 min. Chromatograms showing retention times of a common phthalate, DINP (Figure 2),and a UV absorber, Chimassorb 81 (Figure 3). These chromatograms wererepresentative of the results observed for all plastics additives measured using theGPC clean-up protocol described. Figure 2. Chromatogram Showing Retention Time of Diisononyl phthalate (DINP). ( T el ep hon e : 8 00 - 4 45 - 7 6 61 ) Figure 3. Chromatogram Showing Retention Time of Chimassorb 81. All plastic additives separated from the representative edible oil (corn oil), as shownbelow in Table 2. Compound RT (min) Corn Oil 12.6 lrganox 1076 13.7 DINP 15.1 DNOP 15.5 DEHP 15.6 DIBP 17.1 Uvitex OB 17.5 DBP 17.6 Chimassorb 81 17.7 BBP 18.5 DEP 19.3 Methoxychlor (GPC Std) 19.7 DPP 19.9 DMP 21 Perylene (GPC Std) 38.6 Table 2. Retention Times for Plasticizer Additives, Corn Oil and GPC Standards (ForAbbreviation Key See Table 1). Gel permeation chromatography using the Gilson Automated GX-271 GPC Clean-upSystem is an efficient clean-up technique to separate phthalates and other plasticsadditives from fatty foods including edible oils, as shown in this application note. Asconcern over the potential toxicity and adverse human health effects associatedwith inadvertent exposure to chemicals compounded with plastic food packaginggrows, so does demand for the development of efficient methods by which toseparate and accurately measure the levels of such additives in food products.Automation of GPC improves laboratory efficiency, thereby enabling the rapid clean-up of food samples containing high molecular weightinterferences prior todownstream analyses. References 1. Meeker,J.D.,Sathyanarayana,S.,Swan, S.H. Phthalates and other additivesin plastics: human exposure and associated health outcomes. Phil. Trans. R.Soc.B (2009) 364:2097-2113. Gilson, Inc.Page| Gilson, Inc.Middleton, WI USA Plastics are ubiquitous in our society and are extensively used in a large variety ofpackaged foods. A variety of chemicals that enhance the physical quality of plasticsare often added as well. Some commonly used additives include plasticizers (suchas phthalates) to improve flexibility, UV filters for protection from sunlight,brightening agents, coloring agents, and preservatives. Enhanced by a number ofenvironmental factors, some of these additives may migrate into food products thathave been packaged using plastics. There is currently a great deal of interest inmeasuring the migration of these compounds into food products, as considerableuncertainty exists regarding the human health risks associated with exposure tosuch compounds.Gel permeation chromatography (GPC) is a highly effective method for the removalof high molecular weight interferences such as lipids from a fatty food prior toanalysis for the compounds of interest. GPC has been used to clean up fatty foodscontaminated with plasticizers and other plastics additives.This note describes the use of GPC clean‐upto separate a variety of plastics additives,such as phthalates, Chimassorb® 81 (a UVabsorber and stabilizer), Irganox® 1076 (anoptical brightener) and Uvitex® OB (anantioxidant and thermal stabilizer) from arepresentative edible oil sample prior toanalysis.

确定

还剩3页未读,是否继续阅读?

香港华运有限公司为您提供《Edible Oils中N,N''-二甲基-N,N''-二(苯甲基)-1,2-乙二胺检测方案(GPC)》,该方案主要用于Edible Oils中N,N''-二甲基-N,N''-二(苯甲基)-1,2-乙二胺检测,参考标准--,《Edible Oils中N,N''-二甲基-N,N''-二(苯甲基)-1,2-乙二胺检测方案(GPC)》用到的仪器有

相关方案

更多