方案详情

文

表面活性剂在许多生产制造过程中被广泛使用,临界胶束浓度(CMC)对表面活性剂在各个领域的应用具有重要意义。本文采用光学接触角仪对表面活性剂SDS的临界胶束浓度进行了测定。

方案详情

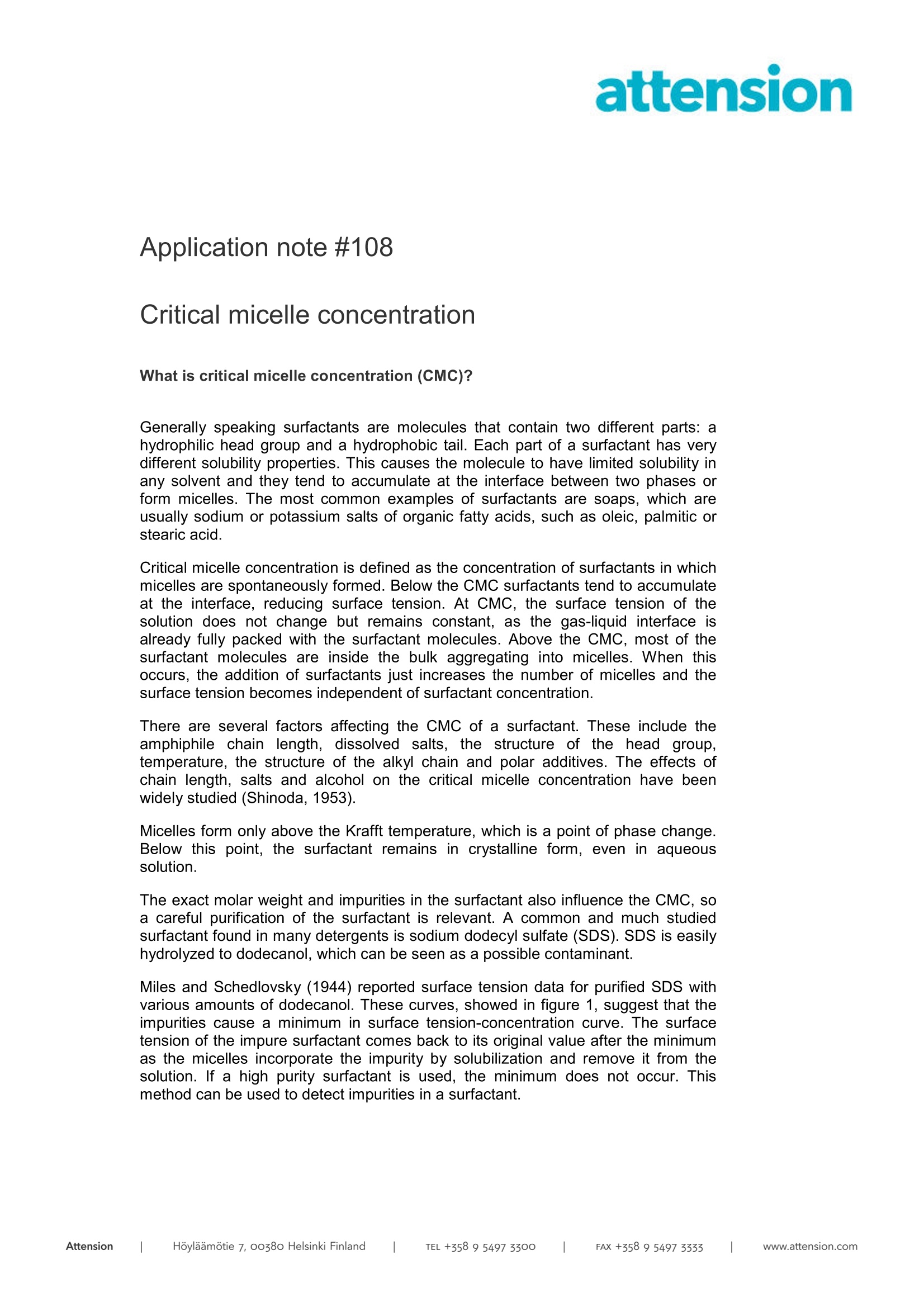

Application note #108Criticalmicelle concentration What is critical micelle concentration (CMC)? Generally speaking surfactants are molecules that contain two different parts: ahydrophilic head group and a hydrophobic tail.Each part of a surfactant has verydifferent solubility properties. This causes the molecule to have limited solubility inany solvent and they tend to accumulate at the interface between two phases orform micelles. The most common examples of surfactants are soaps, which areusually sodium or potassium salts of organic fatty acids, such as oleic, palmitic orstearic acid. Critical micelle concentration is defined as the concentration of surfactants in whichmicelles are spontaneously formed. Below the CMC surfactants tend to accumulateat the interface, reducing surface tension. At CMC, the surface tension of thesolution does not change but remains constant, as the gas-liquid interface isalready fully packed with the surfactant molecules. Above the CMC, most of thesurfactant molecules are inside the bulk aggregating into micelles. When thisoccurs, the addition of surfactants just increases the number of micelles and thesurface tension becomes independent of surfactant concentration. There are several factors affecting the CMC of a surfactant. These include theamphiphile chain length, dissolved salts, the structure of the head group,temperature, the structure of the alkyl chain and polar additives. The effects ofchain length, salts and alcohol on the critical micelle concentration have beenwidely studied (Shinoda, 1953). Micelles form only above the Krafft temperature, which is a point of phase change.Below this point, the surfactant remains in crystalline form, even in aqueoussolution. The exact molar weight and impurities in the surfactant also influence the CMC, soa careful purification of the surfactant is relevant. A common and much studiedsurfactant found in many detergents is sodium dodecyl sulfate (SDS). SDS is easilyhydrolyzed to dodecanol, which can be seen as a possible contaminant. Miles and Schedlovsky (1944) reported surface tension data for purified SDS withvarious amounts of dodecanol. These curves, showed in figure 1, suggest that theimpurities cause a minimum in surface tension-concentration curve. The surfacetension of the impure surfactant comes back to its original value after the minimumas the micelles incorporate the impurity by solubilization and remove it from thesolution. If a high purity surfactant is used, the minimum does not occur. Thismethod can be used to detect impurities in a surfactant. Figure 1. Surface tension data of sodium dodecyl sulfate with various amounts ofcontamination (dodecanol). Replotted data of Miles and Schedlovsky (1944). Why measure CMC? CMC is an important characteristic of a surfactant. From thermodynamics of micelleformation, useful relations between free energies and surfactant chemical potentialscan be obtained. It also provides clear relations for enthalpy and entropy. Theequation combined with the Gibbs-Helmholtz equation provides an expression for theenthalpy of micelle formation The equilibrium and transportation properties (optical density and electricalconduction) of the solution are affected by the aggregation process at the criticalmicelle concentration. The manufacture of surfactants is a major commercial enterprise. Surfactants aremostly used in soap and detergent industries. The surfactant industry is interestedin optimizing the amount of detergent and minimizing waste. These studies requirea closer look of the surfactant CMC. The important aspect of detergentmanufacturing is the phenomenon of solubilization in micelle formation. A waterinsoluble organic compound can be “dissolved”in a surfactant solution as it canmove to the oily interior of the micelle. The surfactant micelles can also stabilize anoil-water emulsion by absorbing on a surface of an oil droplet. Commercialdetergents contain a mixture of surfactants. These impure substances are cheaperand easier to manufacture. Mixing of surfactants also often improves theperformance of a detergent. Sarmoria, Puvvada and Blankschtein have studied theCMC prediction of nonideal binary surfactant mixtures (Langmuir 1992, 8, 2690-2697). The critical micelle concentration is a useful measure also in pharmacology andtechnology. Silicon surfactants are important in pharmaceutical and cosmeticindustry due to their low price and technological advantages (Baquerizo, Holgado,Cabrerizo, Gallardo, 2000). Studies on interfacial properties of lysophospholipidsrequire the full understanding of the molecule’s CMC (Stafford, Fanni and Dennis,1989). Liposomes can be used to carry non-polar drug molecules in blood. A significant use for CMC is the process of emulsion polymerization. It is atechnologically and commercially important reaction that can be used to synthesizealternatives to natural latex rubber. Emulsion polymerization is carried in thesurfactant's critical micelle concentration. The CMC of the surfactant is an importantfactor in the particle nucleation process. The latex particles are thermodynamicallyunstable and can be stabilized by a mixture of surfactants. Usually these surfactantmixtures are a combination of anionic and non-ionic surfactants such as SDS andnonyphenol polyethoxylate (Chen, Lin, Chern, Wu, 1997). The CMCs of thesesurfactant mixtures are lower than the CMCs of the pure surfactants. This is due tothe interactions between the different surfactant molecules in the formation of mixedmicelles. The emulsions obtained with the emulsion polymerization method can beused in glue, coating, PVC and rubber manufacturing. Conclusion CMC studies have been known to be important for decades in all areas containingsurfactants. Surfactants are relevant in many chemical manufacturing processesand therefore precise and accurate results of CMC studies are essential in order forthese processes to be successful. References Atkins Peter, Physical Chemistry, Oxford University Press, 2006 Attension application note #103 CMC theory and measurement techniques Barnes G.T., Gentle I.R., Interfacial Science, An Introduction, Oxfor UniversityPress, 2005 Baquerizo, Holgado, Cabrerizo and Gallardo, II Farmaco,55, (2000), 583-589 Chen Li-Jen, Lin Shi-Yow, Chern Chorng-Syan, Wu Shuo-Cheng, Colloids andsurfaces A: Physicochemical and Engineering Aspects 122 (1997) 161-168 Evans D. Fennel, Wennesrtrom Hakan, The Colloidal Domain, Wiley-VCH, 1999 Hunter Robert J., Introduction to Modern Colloid Science, Oxford SciencePublications Sarmoria Claudia, Sudhakar Puvvada and Daniel Blankschtein, Langmuir 1992, 8,2690-2697 Seppala Jukka, Polymeeriteknologian Perusteet, Otatieto 1997 Shinoda Kozo, Bulletin of the Chemical Society of Japan, February 1953 Sjoblom Johan, Emulsions - A fundamental and Practical Approach, Series C:Mathematical and Physical Sciences - Vol. 363 Stafford Richard E., Fanni Tahsin and Dennis Edward A., Biochemistry 1989, 28,5113-5120 AttensionHoylaamotie , Helsinki FinlandTEL +ww.attension.comFAX + AttensionTEL +oylaamotie , Helsinki Finlandwww.attension.comFAX +

确定

还剩2页未读,是否继续阅读?

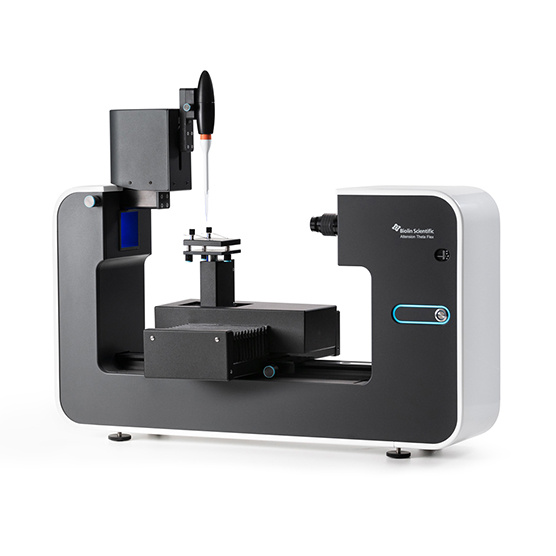

瑞典百欧林科技有限公司为您提供《表面活性剂中临界胶束浓度检测方案 》,该方案主要用于其他中临界胶束浓度检测,参考标准--,《表面活性剂中临界胶束浓度检测方案 》用到的仪器有Attension Theta Flex 光学接触角仪、Theta Lite 光学接触角仪

相关方案

更多

该厂商其他方案

更多