方案详情

文

Modulated DSC is a powerful tool for materials characterization. Like any other precision technique, failure to use the optimum experimental conditions can result in sub-par performance. Following the suggestions listed in this paper should help you to design your MDSC experiment so that you derive the highest quality data.

方案详情

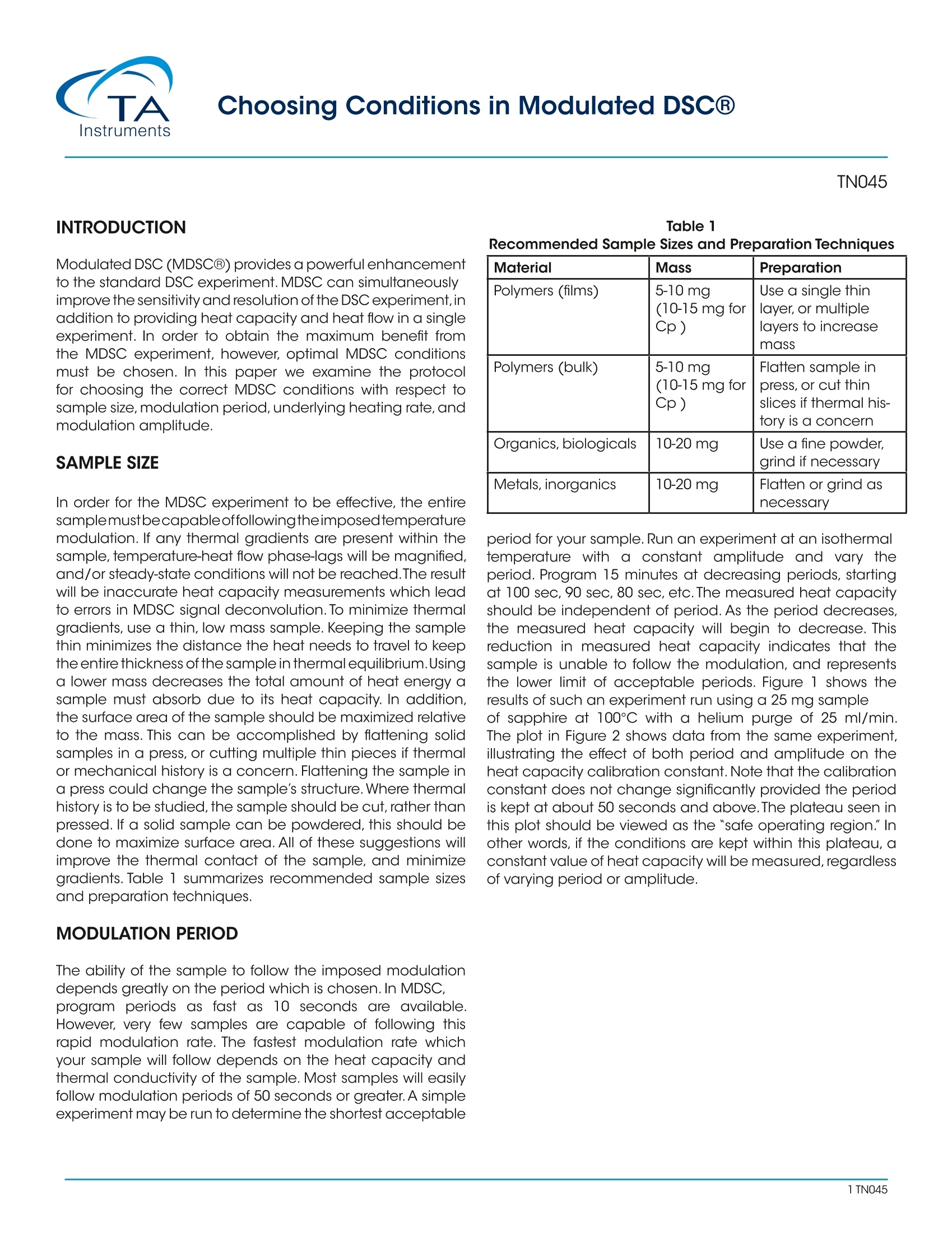

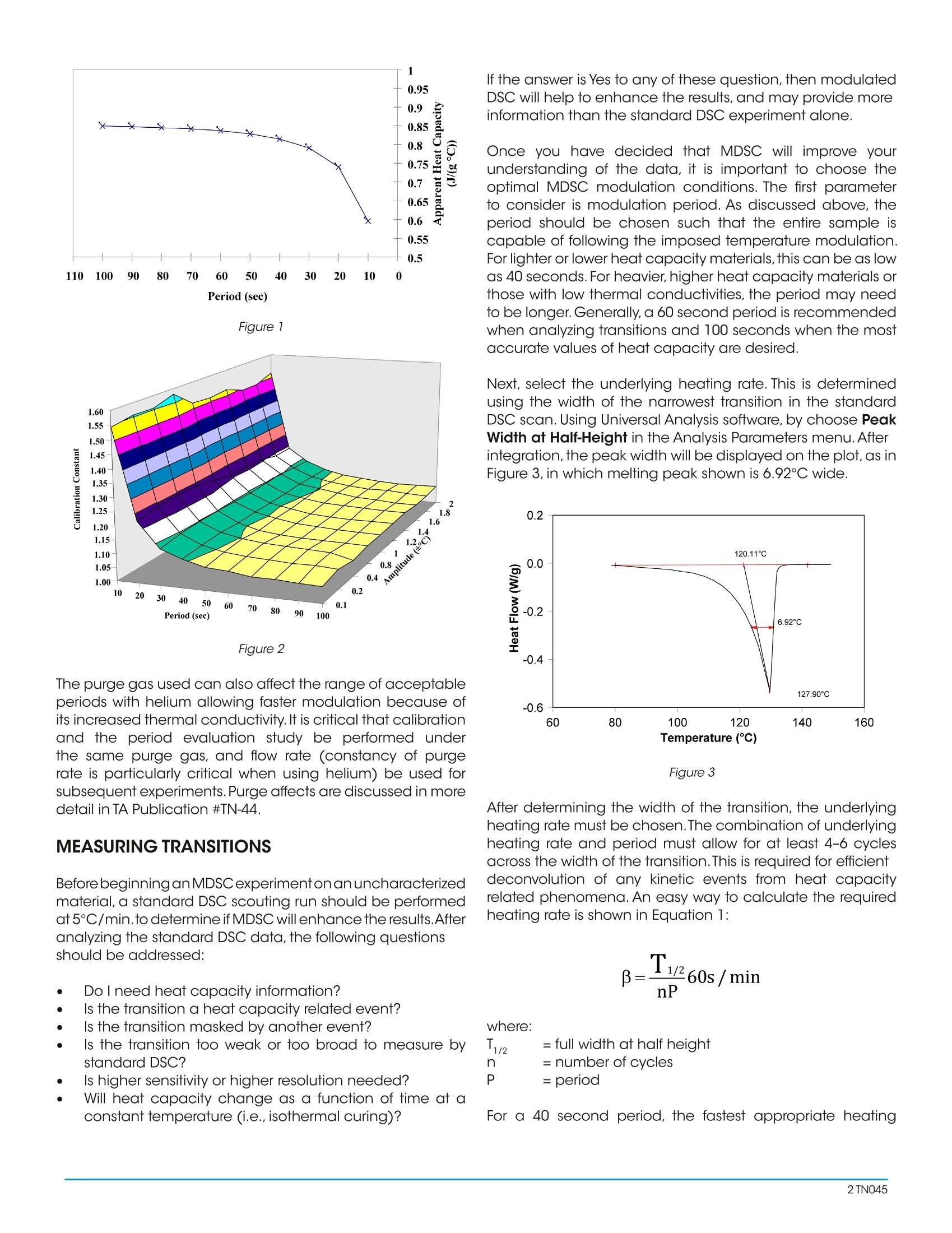

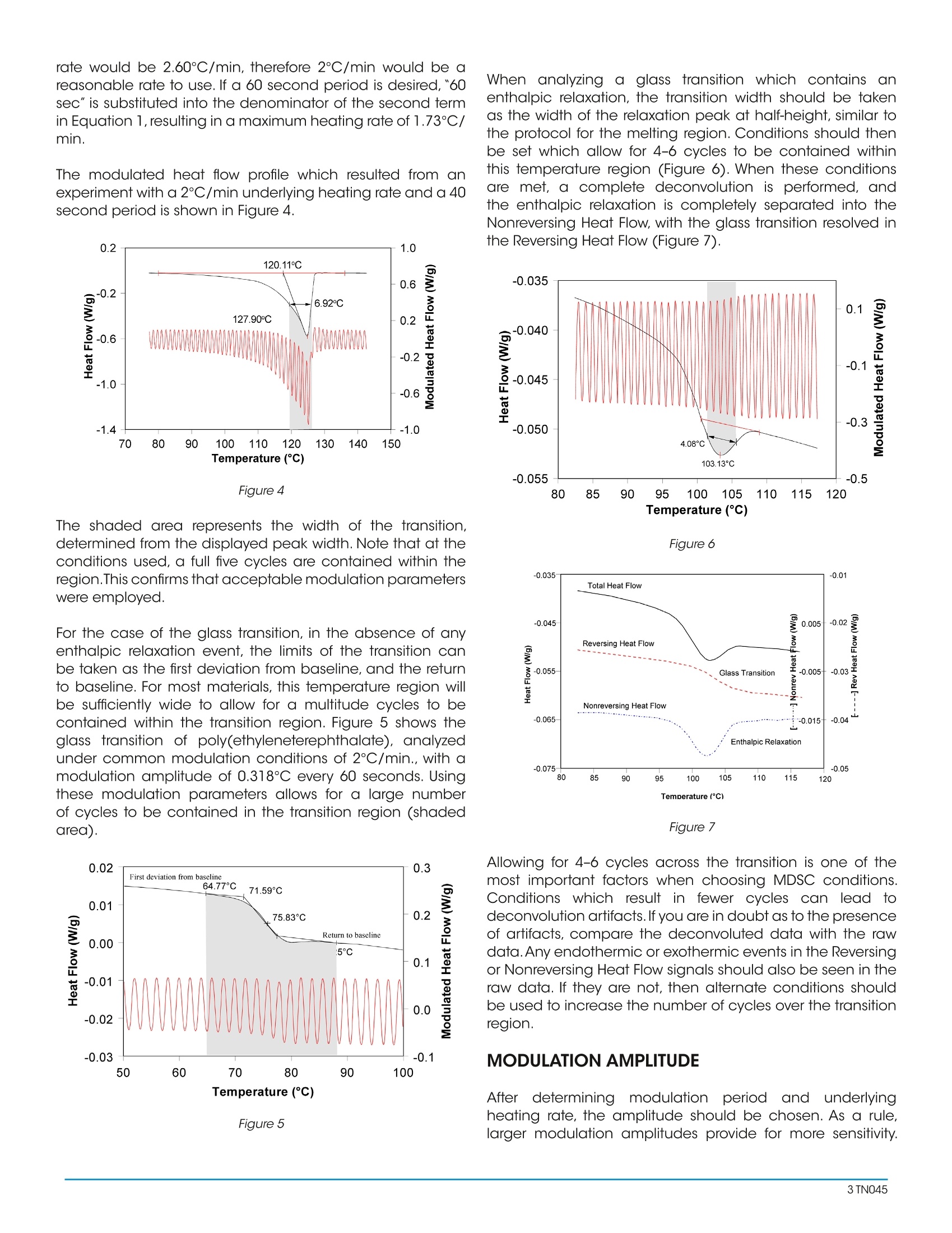

Choosing Conditions in Modulated DSCQ Modulated DSC (MDSCQ) provides a powerful enhancementto the standard DSC experiment.MDSC can simultaneouslyimprove the sensitivity and resolution of the DSC experiment,inaddition to providing heat capacity and heat flow in a singleexperiment. In order to obtain the maximum benefit fromthe MDSC experiment, however, optimal MDSC conditionsmust be chosen. In this paper we examine the protocolfor choosing the correct MDSC conditions with respect tosample size, modulation period, underlying heating rate, andmodulation amplitude. SAMPLE SIZE In order for the MDSC experiment to be effective, the entiresamplemustbecapableoffollowingtheimposedtemperaturemodulation. If any thermal gradients are present within thesample, temperature-heat flow phase-lags will be magnified,and/or steady-state conditions will not be reached.The resultwill be inaccurate heat capacity measurements which leadto errors in MDSC signal deconvolution. To minimize thermalgradients, use a thin, low mass sample. Keeping the samplethin minimizes the distance the heat needs to travel to keepthe entire thickness of the sample in thermal equilibrium.Usinga lower mass decreases the total amount of heat energy asample must absorb due to its heat capacity. In addition,the surface area of the sample should be maximized relativeto the mass. This can be accomplished by flattening solidsamples in a press, or cutting multiple thin pieces if thermalor mechanical history is a concern. Flattening the sample ina press could change the sample's structure. Where thermalhistory is to be studied, the sample should be cut, rather thanpressed. If a solid sample can be powdered, this should bedone to maximize surface area. All of these suggestions willimprove the thermal contact of the sample, and minimizegradients. Table 1 summarizes recommended sample sizesand preparation techniques. MODULATION PERIOD The ability of the sample to follow the imposed modulationdepends greatly on the period which is chosen. In MDSC,program periods as fast as 10 seconds are available.However, very few samples are capable of following thisrapid modulation rate. The fastest modulation rate whichyour sample will follow depends on the heat capacity andthermal conductivity of the sample. Most samples will easilyfollow modulation periods of 50 seconds or greater. A simpleexperiment may be run to determine the shortest acceptable Table 1Recommended Sample Sizes and Preparation Techniques Material Mass Preparation Polymers (films) 5-10 mg(10-15 mg forCp) Use a single thin layer, or multiple layers to increasemass Polymers (bulk) 5-10mg(10-15 mg forCp) Flatten sample in press, or cut thinslices if thermal his- tory is a concern Organics, biologicals 10-20 mg Use a fine powder, grind if necessary Metals, inorganics 10-20 mg Flatten or grind asnecessary period for your sample.Run an experiment at an isothermaltemperature with a constant amplitude and vary theperiod. Program 15 minutes at decreasing periods, startingat 100 sec, 90 sec, 80 sec, etc.The measured heat capacityshould be independent of period. As the period decreases,the measured heat capacity will begin to decrease. Thisreduction in measured heat capacity indicates that thesample is unable to follow the modulation, and representsthe lower limit of acceptable periods. Figure 1 shows theresults of such an experiment run using a 25 mg sampleof sapphire at 100℃ with a helium purge of 25 ml/min.The plot in Figure 2 shows data from the same experiment,illustrating the effect of both period and amplitude on theheat capacity calibration constant. Note that the calibrationconstant does not change significantly provided the periodis kept at about 50 seconds and above.The plateau seen inthis plot should be viewed as the "safe operating region." Inother words, if the conditions are kept within this plateau, aconstant value of heat capacity will be measured, regardlessof varying period or amplitude. Period (sec) Figure 1 2 1.8 Figure 2 The purge gas used can also affect the range of acceptableperiods with helium allowing faster modulation because ofits increased thermal conductivity. It is critical that calibrationand the period evaluation study be performedunderthe same purge gas, and flow rate (constancy of purgerate is particularly critical when using helium) be used forsubsequent experiments.Purge affects are discussed in moredetail in TA Publication #TN-44. MEASURING TRANSITIONS BeforebeginninganMDSCexperimentonan uncharacterizedmaterial, a standard DSC scouting run should be performedat 5°C/min.to determine ifMDSC will enhance the results.Afteranalyzing the standard DSC data, the following questionsshould be addressed: Do I need heat capacity information? Is the transition a heat capacity related event? Is the transition masked by another event? ls the transition too weak or too broad to measure bystandard DSC? Is higher sensitivity or higher resolution needed? Will heat capacity change as a function of time at aconstant temperature (i.e.,isothermal curing)? If the answer is Yes to any of these question, then modulatedDSC will help to enhance the results, and may provide moreinformation than the standard DSC experiment alone. Once you have decided that MDSC will improve yourunderstanding of the data, it is important to choose theoptimal MDSC modulation conditions. The first parameterto consider is modulation period. As discussed above, theperiod should be chosen such that the entire sample iscapable of following the imposed temperature modulation.For lighter or lower heat capacity materials, this can be as lowas 40 seconds. For heavier, higher heat capacity materials orthose with low thermal conductivities, the period may needto be longer.Generally, a 60 second period is recommendedwhen analyzing transitions and 100 seconds when the mostaccurate values of heat capacity are desired. Next, select the underlying heating rate.This is determinedusing the width of the narrowest transition in the standardDSC scan. Using Universal Analysis software, by choose PeakWidth at Half-Height in the Analysis Parameters menu.Afterintegration, the peak width will be displayed on the plot, as inFigure 3,in which melting peak shown is 6.92℃ wide. Figure 3 After determining the width of the transition, the underlyingheating rate must be chosen.The combination of underlyingheating rate and period must allow for at least 4-6 cyclesacross the width of the transition.This is required for efficientdeconvolution of any kinetic events from heat capacityrelated phenomena. An easy way to calculate the requiredheating rate is shown in Equation 1: where:1/2 = full width at half heightumber of cycles =nP= periodFor a 40 second period, the fastest appropriate heating rate would be 2.60°C/min, therefore 2°C/min would be areasonable rate to use. lf a 60 second period is desired,"60sec"is substituted into the denominator of the second termin Equation 1, resulting in a maximum heating rate of 1.73C/min. The modulated heat flow profile which resulted from anexperiment with a 2℃/min underlying heating rate and a 40second period is shown in Figure 4. Figure 4 The shaded area represents the width of the transition,determined from the displayed peak width.Note that at theconditions used, a full five cycles are contained within theregion.This confirms that acceptable modulation parameterswere employed. For the case of the glass transition, in the absence of anyenthalpic relaxation event, the limits of the transition canbe taken as the first deviation from baseline, and the returnto baseline. For most materials, this temperature region willbe sufficiently wide to allow for a multitude cycles to becontained within the transition region. Figure 5 shows theglass transition of poly(ethyleneterephthalate), analyzedunder common modulation conditions of 2°C/min., with amodulation amplitude of 0.318℃ every 60 seconds. Usingthese modulation parameters allows for a large numberof cycles to be contained in the transition region (shadedarea). Figure 5 When analyzing a glass transition which contains anenthalpic relaxation, the transition width should be takenas the width of the relaxation peak at half-height, similar tothe protocol for the melting region. Conditions should thenbe set which allow for 4-6 cycles to be contained withinthis temperature region (Figure 6). When these conditionsare met, a complete deconvolution is performed, andthe enthalpic relaxation is completely separated into theNonreversing Heat Flow, with the glass transition resolved inthe Reversing Heat Flow (Figure 7). Temperature (C) Figure 6 Figure 7 Allowing for 4-6 cycles across the transition is one of themost important factors when choosing MDSC conditions.Conditions which result in fewer cycles can lead todeconvolution artifacts. If you are in doubt as to the presenceof artifacts, compare the deconvoluted data with the rawdata.Any endothermic or exothermic events in the Reversingor Nonreversing Heat Flow signals should also be seen in theraw data. If they are not, then alternate conditions shouldbe used to increase the number of cycles over the transitionregion. MODULATION AMPLITUDE After determining modulation period and underlyingheating rate, the amplitude should be chosen. As a rule,larger modulation amplitudes provide for more sensitivity. As seen in Figure 2, the measured value of heat capacity isnot dependent on the amplitude, provided the mass of thesample is sufficiently small as to provide thermal equilibrium. When a dynamic underlying heating rate is chosen, thereare two main types of experiments available: modulatedheat-cool or modulated heat-only. The temperature profilescorresponding to each are shown in Figure 8. Figure 8 In the modulated heat-only profile, the modulatedtemperature (solid line) never decreases, i.e., the sampleis never cooled. In the modulated heat-cool profile, somecooling of the sample is encountered on each modulationcycle. For general MDSC experiments, and for the measurement ofheat capacity or the glass transition, the modulated heat-cool profile is recommended.This profile provides for the bestsensitivity for weak transitions and improves the precisionof heat capacity measurements. The modulated heat-onlyprofile is a special case condition and should be used whenstudying melting or simultaneous melting/crystallizationphenomena. In these cases, cooling the sample may inducecrystallization. To prevent crystallization from occurring (andpotentially complicating the measurement), the modulatedheat-only profile is used. The table below can be used to determine the maximumheat-only amplitude for a given underlying heating rate andperiod. Table 2 HeatingRate(°C/min) 40 50 60 70 80 90 100 0.1 0.011 0.013 0.016 0.019 0.021 0.024 0.027 0.2 0.021 0.027 0.032 0.037 0.042 0.048 0.053 0.5 0.053 0.066 0.080 0.093 0.106 0.119 0.133 1.0 0.106 0.133 0.159 0.186 0.212 0.239 0.265 2.0 0.212 0.265 0.318 0.371 0.424 0.477 0.531 5.0 0.531 0.663 0.796 0.928 1.061 1.194 1.326 lf the period and heating rate were 60 seconds and 2℃/min, respectively, the maximum heat only amplitude would be ±0.318℃.Amplitudes less than this value will still provideheat-only conditions, but an amplitude greater than thisvalue will represent a modulated heat-cool condition. Thistable is additive, i.e. if a value for a heating rate of 2.5℃/min.is required, adding the values for 2.0℃/min and 0.5℃/minwill provide the required value. The amplitudes calculatedfrom this table result in a minimum heating rate of 0℃/min. Use of these zero heating rate amplitudes providesadditional insight in understanding the melting phenomena.The melting phenomena is discussed in more detail in TAPublication Number TA-227. SUMMARY Modulated DSC is a powerfultool formaterialscharacterization. Like any other precision technique, failureto use the optimum experimental conditions can result insub-par performance. Following the suggestions listed in thispaper should help you to design your MDSC experiment sothat you derive the highest quality data. For more information or to place an order, go tohttp://www.tainstruments.com to locate your local salesoffice information. N INTRODUCTIONModulated DSC (MDSC®) provides a powerful enhancement to the standard DSC experiment. MDSC can simultaneously improve the sensitivity and resolution of the DSC experiment, in addition to providing heat capacity and heat flow in a single experiment. In order to obtain the maximum benefit from the MDSC experiment, however, optimal MDSC conditions must be chosen. In this paper we examine the protocol for choosing the correct MDSC conditions with respect to sample size, modulation period, underlying heating rate, and modulation amplitude.

确定

还剩2页未读,是否继续阅读?

TA仪器为您提供《采用调制DSC中膨胀和收缩做同步分析检测方案(差示扫描量热)》,该方案主要用于其他中膨胀和收缩做同步分析检测,参考标准--,《采用调制DSC中膨胀和收缩做同步分析检测方案(差示扫描量热)》用到的仪器有TA仪器 Discovery差示扫描量热仪

相关方案

更多