方案详情

文

本文介绍了S3(Small Sensor System,小传感器系统)装置的应用,该装置配备了六个金属氧化物半导体(MOX)气体传感器阵列,并结合浸提作为一种新的方法来表征香醋的芳香族分布。事实上,由于这一过程,从香醋中提取了亲脂性挥发性化合物,而乙酸及其衍生物的高浓度对MOX传感器灵敏度没有影响。研究结果表明,该方法在BVs质量评价中具有巨大的潜力。所有样品均采用气相色谱-质谱(GC-MS)和固相微萃取(SPME)并行分析。

方案详情

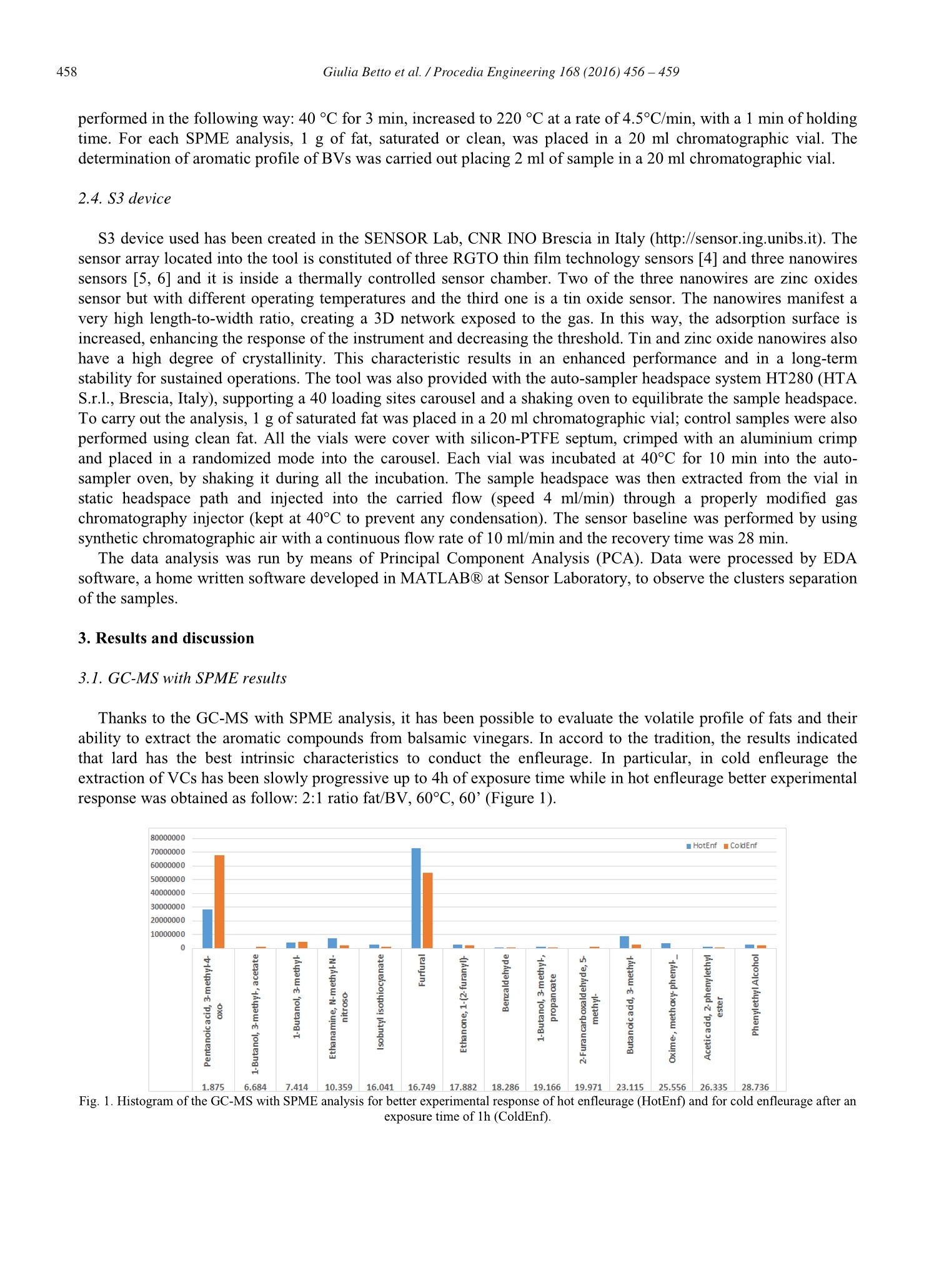

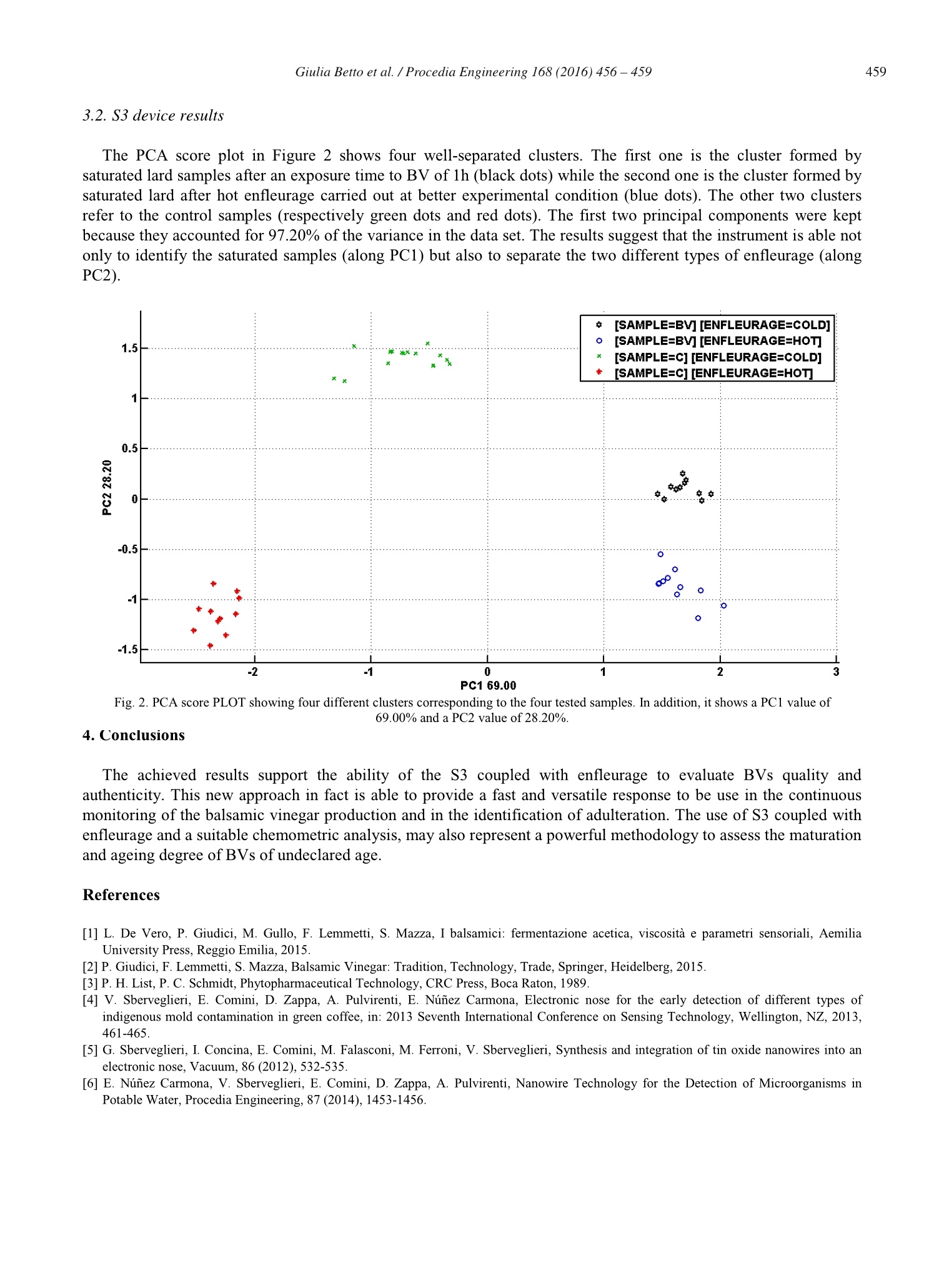

Available online at www.sciencedirect.comProcediaEngineeringScienceDirectCrossMarkProcedia Engineering 168 (2016)456-459www.elsevier.com/locate/procedia 457Giulia Betto et al./Procedia Engineering 168 (2016) 456-459 Peer-review under responsibility of the organizing committee of the 30th Eurosensors Conferencedoi:10.1016/j.proeng.2016.11.545 30th Eurosensors Conference, EUROSENSORS 2016 A new approach to evaluate vinegars quality: application of SmallSensor System (S3) device coupled with enfleurage Giulia Betto, Veronica Sberveglierib*, Estefania Núnez Carmonaa,b, Elisabetta Cominiab,Paolo Giudici “University of Brescia, Department of Information Engineering, Via Branze 45, 25123 Brescia, Italy 'CNR-INO SENSOR Lab,Via Valotti 9, 25123 Brescia, Italy ‘University of Modena and Reggio Emilia, Department of Life Sciences, Via Amendola 2, 42124 Reggio Emilia, Italy Abstract In this work is illustrated the application of S3 (Small Sensor System) device, equipped with an array of six metal oxidesemiconductor (MOX) gas sensors, coupled with enfleurage as new approach to characterize the aromatic profile of BalsamicVinegars (BVs). Thanks to the enfleurage in fact, the lipophilic volatile compounds are extracted from balsamic vinegar whileacetic acid and its derivatives whose high concentration negatively influences MOX sensors sensitivity are not involved in theprocess. The obtained results show the huge potentiality of this new approach to evaluate BVs quality. All the samples wereanalyzed in parallel by GC-MS (Gas Chromatography-Mass Spectrometry) with SPME (Solid Phase Micro-Extraction). @ 2016 Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/). Peer-review under responsibility of the organizing committee of the 30th Eurosensors Conference Keywords: MOX gas sensors; GC-MS with SPME; Balsamic Vinegars; Enfleurage. 1. Introduction Vinegar production is a process that uses relatively low-cost raw materials, such as grapes, apples, pears, honey,syrups, cereals, hydrolyzed starches, beer and wine, to obtain products with a relatively high price [1]. Italianbalsamic vinegars produced from regional foodstuffs according to well-established methods are one of the productgroups that mainly take advantage of the use of “poor”raw materials. ( * Veronica Sberveglieri. Tel.: + 39-320-4377973. ) ( E-mail address: veronica.sbervelieri@ino.it ) 1877-7058 @ 2016 Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/). The entire production of BVs is concentrated in the Emilia Romagna region: Balsamic Vinegar of Modena(BVM) with PGI (Protected Geographical Indication) status and Traditional Balsamic Vinegar with PDO (ProtectedDenomination of Origin) status [2]. BVM and TBV have a high content of volatile compounds (VCs) that contributeto determine an unmistakable and worldwide-appreciated aroma. Therefore, the characterization of the aromaticprofile of BVs is one of the most important factors in quality control and authenticity assessment of the product. The aim of this work was to establish a new approach to permit the application of S3 device in the evaluation ofBVM and TBVs quality and authenticity. S3 device in fact is a very easy-to-use, fast, accurate, low powerconsumption, cost-effective and portable tool that can become a valuable alternative for classical expensive methodsof aromatic profile characterization such as chemical analysis and sensory analysis. Since the MOX gas sensors aresensitive to a high concentration of acids, such as acetic acid that is widely present in BVs, before the analysis ofVCs it was carried out the enfleurage, an ancient technique based on the ability of solid fats at room temperature toabsorb, dissolve and bind the aromatic compounds [3]. 2. Materials and methods 2.1.Samples Balsamic vinegars, with different residence time, were kindly provided by Acetaia Giudici (Reggio Emilia, Italy).Before each analysis, the pH of the samples has been adapted adding solid NaHCO3. To understand the best way toconduct the enfleurage, six types of fats with different origin (animal, vegetable and synthetic) were selected: lard,butter,PSFA (Palmitic Saturated Fatty Acid), margarine, paraffin and vaseline. 2.2.Enfleurage Enfleurage was carried out under cold and hot conditions, as shown in Table 1. Table 1. Comparison between the processes of cold and hot enfleurage. The fat was heated to its melting point and poured into aPetri dish (9 cmx 1.5 cm) in order to obtain a 3 mm-thicklayer. After the melted fat hass cooleddown1oatroomtemperature, 20 ml of balsamic vinegar, corresponding toa 3 mm-thick, was added to fat layer. The Petri dishes were closed and placed in an incubator at25°℃ for 1-8h. The saturated fat was physically separated from thesupernatantliquid andd:subjected to 1low-temperaturecentrifugal separation. Balsamic vinegar was directly added into the melted fat. The blend was repeated using 1:2,1:1 and 2:1 ratios of fatand balsamic vinegar. The mixture was warmed at 40, 50 and 60 C and stirredat 300rpm for 30, 60 and 90 min. Afteraa centrifugal separationcarried out at lowtemperature, the saturated fat was physically removedfrom the supernatant liquid. GC-MS analysis was performed using a Shimadzu Gas Chromatograph GC2010 PLUS (Kyoto, KYT, Japan)equipped with a Shimadzu single quadrupole Mass Spectrometer MSQP2010 (Kyoto, KYT, Japan) ultra and aHT280T auto-sampler (HTA S.r.l., Brescia, Italy) that permitted SPME analysis. The vials were incubated in anoven thermostatically regulated at 40℃ for 15 minutes due to create the headspace equilibrium. In order to extractthe volatile compounds of the samples was used a DVB/CAR/PDMS (50/30um) (Supelco Co., Bellefonte, PA,USA) SPME fiber. To provide the adsorption of volatile compounds, the SPME fiber was exposed to the headspaceof the vials for 15 minutes at 40℃. For desorption of the compounds, the fiber was placed in the injector of theheated GC for 6 min at 220°C. Volatile compounds were separated using an analytical capillary column (DB-WAXcapillary column, 30m x 0.25 mm x 0.25um, Agilent Technologies, Santa Clara, CA, USA) and the carrier gas wasultrapure helium (99.99%) at a constant flow rate of 1.5 ml/min. The temperature program for the GC was performed in the following way: 40 °℃ for 3 min, increased to 220 ℃ at a rate of 4.5°C/min, with a 1 min of holdingtime. For each SPME analysis, 1 g of fat, saturated or clean, was placed in a 20 ml chromatographic vial. Thedetermination of aromatic profile of BVs was carried out placing 2 ml of sample in a 20 ml chromatographic vial. 2.4. S3 device S3 device used has been created in the SENSOR Lab, CNR INO Brescia in Italy (http://sensor.ing.unibs.it). Thesensor array located into the tool is constituted of three RGTO thin film technology sensors [4] and three nanowiressensors [5, 6] and it is inside a thermally controlled sensor chamber. Two of the three nanowires are zinc oxidessensor but with different operating temperatures and the third one is a tin oxide sensor. The nanowires manifest avery high length-to-width ratio, creating a 3D network exposed to the gas. In this way, the adsorption surface isincreased, enhancing the response of the instrument and decreasing the threshold. Tin and zinc oxide nanowires alsohave a high degree of crystallinity. This characteristic results in an enhanced performance and in a long-termstability for sustained operations. The tool was also provided with the auto-sampler headspace system HT280 (HTAS.r.l., Brescia, Italy), supporting a 40 loading sites carousel and a shaking oven to equilibrate the sample headspace.To carry out the analysis, 1 g of saturated fat was placed in a 20 ml chromatographic vial; control samples were alsoperformed using clean fat. All the vials were cover with silicon-PTFE septum, crimped with an aluminium crimpand placed in a randomized mode into the carousel. Each vial was incubated at 40°C for 10 min into the auto-sampler oven, by shaking it during all the incubation. The sample headspace was then extracted from the vial instatic headspace path and injected into the carried flow (speed 4 ml/min) through a properly modified gaschromatography injector (kept at 40°C to prevent any condensation). The sensor baseline was performed by usingsynthetic chromatographic air with a continuous flow rate of 10 ml/min and the recovery time was 28 min. The data analysis was run by means of Principal Component Analysis (PCA). Data were processed by EDAsoftware, a home written software developed in MATLAB@ at Sensor Laboratory, to observe the clusters separationof the samples. 3. Results and discussion 3.1.GC-MS with SPME results Thanks to the GC-MS with SPME analysis, it has been possible to evaluate the volatile profile of fats and theirability to extract the aromatic compounds from balsamic vinegars. In accord to the tradition, the results indicatedthat lard has the best intrinsic characteristics to conduct the enfleurage. In particular, in cold enfleurage theextraction of VCs has been slowly progressive up to 4h of exposure time while in hot enfleurage better experimentalresponse was obtained as follow: 2:1 ratio fat/BV, 60°C, 60’(Figure 1). Fig. 1. Histogram of the GC-MS with SPME analysis for better experimental response of hot enfleurage (HotEnf) and for cold enfleurage after anexposure time of 1h (ColdEnf). 3.2. S3 device results The PCA score plot in Figure 2 shows four well-separated clusters. The first one is the cluster formed bysaturated lard samples after an exposure time to BV of 1h (black dots) while the second one is the cluster formed bysaturated lard after hot enfleurage carried out at better experimental condition (blue dots). The other two clustersrefer to the control samples (respectively green dots and red dots). The first two principal components were keptbecause they accounted for 97.20% of the variance in the data set. The results suggest that the instrument is able notonly to identify the saturated samples (along PC1) but also to separate the two different types of enfleurage (alongPC2). PC1 69.00 Fig. 2. PCA score PLOT showing four different clusters corresponding to the four tested samples. In addition, it shows a PC1 value of69.00% and a PC2 value of 28.20%. 4. Conclusions The achieved results support the ability of the S3 coupled with enfleurage to evaluate BVs quality andauthenticity. This new approach in fact is able to provide a fast and versatile response to be use in the continuousmonitoring of the balsamic vinegar production and in the identification of adulteration. The use of S3 coupled withenfleurage and a suitable chemometric analysis, may also represent a powerful methodology to assess the maturationand ageing degree of BVs of undeclared age. References ( [1] L. De Vero, P . G i udici, M . Gu l lo, F . Lemmetti, S. M a zz a , I bal s amici: ferme n tazione acetic a , viscosita e par a metri sensor i ali, Aemilia U niversity Press, Reggio Emilia, 2015. ) ( [2] P. Giudici, F. Lemmetti, S. Mazza, Balsamic Vinegar: Tradition, Technology, Trade, Springer, Heidelberg, 2015. ) ( [3] P. H. List, P. C. Schmidt , Phytopharmaceutical Technology, CRC Press, Boca Raton, 1989. ) ( [4] V. S berveglieri, E . C omini, D . Zappa, A. P ul v irenti, E. N un e z Carmo n a, Electronic nose fo r the early de t ection of diffe r ent types of indigenous mold contamination in green coffee, in: 2013 S eventh International Conference on Sensing Technology, Wellington, NZ , 2013, 461-465. ) ( [5] G. Sberveglieri, I . Concina, E. Comini, M. Falasconi, M. F erroni, V. Sber v eglieri, Synthesis and i n tegration of tin oxide nanowi r es into anelectronic nose, Vacuum, 86 ( 2012),532-535. ) ( [6] E. Nunez Carmona, V. Sb e rveglieri, E. Comini, D. Zappa, A. P ul v irenti, Na n owire Technology for the Detection of Microorganisms inPotable W ater, Procedia Engineering, 87 (2014), 1453-1456. ) AbstractIn this work is illustrated the application of S3 (Small Sensor System) device, equipped with an array of six metal oxide semiconductor (MOX) gas sensors, coupled with enfleurage as new approach to characterize the aromatic profile of Balsamic Vinegars (BVs). Thanks to the enfleurage in fact, the lipophilic volatile compounds are extracted from balsamic vinegar while acetic acid and its derivatives whose high concentration negatively influences MOX sensors sensitivity are not involved in the process. The obtained results show the huge potentiality of this new approach to evaluate BVs quality. All the samples were analyzed in parallel by GC-MS (Gas Chromatography-Mass Spectrometry) with SPME (Solid Phase Micro-Extraction).本文介绍了S3(Small Sensor System,小传感器系统)装置的应用,该装置配备了六个金属氧化物半导体(MOX)气体传感器阵列,并结合浸提作为一种新的方法来表征香醋的芳香族分布。事实上,由于这一过程,从香醋中提取了亲脂性挥发性化合物,而乙酸及其衍生物的高浓度对MOX传感器灵敏度没有影响。研究结果表明,该方法在BVs质量评价中具有巨大的潜力。所有样品均采用气相色谱-质谱(GC-MS)和固相微萃取(SPME)并行分析。 Keywords: MOX gas sensors; GC-MS with SPME; Balsamic Vinegars; Enfleurage.关键词:MOX气体传感器;气相色谱-质谱-固相微萃取;香醋;浸提 2.3. GC-MS with SPMEGC-MS analysis was performed using a Shimadzu Gas Chromatograph GC2010 PLUS (Kyoto, KYT, Japan) equipped with a Shimadzu single quadrupole Mass Spectrometer MSQP2010 (Kyoto, KYT, Japan) ultra and a HT280T auto-sampler (HTA S.r.l., Brescia, Italy) that permitted SPME analysis. The vials were incubated in an oven thermostatically regulated at 40ºC for 15 minutes due to create the headspace equilibrium. In order to extract the volatile compounds of the samples was used a DVB/CAR/PDMS (50/30um) (Supelco Co., Bellefonte, PA, USA) SPME fiber. To provide the adsorption of volatile compounds, the SPME fiber was exposed to the headspace of the vials for 15 minutes at 40°C. For desorption of the compounds, the fiber was placed in the injector of the heated GC for 6 min at 220°C. Volatile compounds were separated using an analytical capillary column (DB-WAX capillary column, 30m x 0.25 mm x 0.25um, Agilent Technologies, Santa Clara, CA, USA) and the carrier gas was ultrapure helium (99.99%) at a constant flow rate of 1.5 ml/min. The temperature program for the GC was performed in the following way: 40 °C for 3 min, increased to 220 °C at a rate of 4.5°C/min, with a 1 min of holding time. For each SPME analysis, 1 g of fat, saturated or clean, was placed in a 20 ml chromatographic vial. The determination of aromatic profile of BVs was carried out placing 2 ml of sample in a 20 ml chromatographic vial.GC-MS分析使用岛津气相色谱仪GC2010 PLUS(Kyoto, KYT, Japan),配备岛津单四极杆质谱仪MSQP2010(Kyoto, KYT, Japan)ultra和HT280T自动取样器(HTA S.r.l., Brescia, Italy)进行SPME分析。将小瓶在40℃恒温调节的烘箱中培养15分钟,以达到顶空平衡。为了提取样品中的挥发性化合物,使用了DVB/CAR/PDMS(50/30um)(Supelco Co., Bellefonte, PA, USA)SPME纤维。为了提供挥发性化合物的吸附,SPME纤维在40°C下暴露于小瓶的顶部空间15分钟。为了解吸化合物,将纤维置于220°C下加热的GC注射器中6分钟。使用分析毛细管柱(DB-WAX毛细管柱,30m x 0.25 mm)分离挥发性化合物x 0.25um,Agilent Technologies,Santa Clara,CA,USA),载气为超纯氦(99.99%),恒定流速为1.5 ml/min。GC的温度程序按以下方式执行:40°C持续3分钟,以4.5°C/min的速率增加至220°C,保持时间为1分钟。对于每个SPME分析,将1g饱和或干净的脂肪放入20ml色谱小瓶中。在20ml色谱小瓶中放置2ml样品,测定BVs的芳香族分布。

确定

还剩2页未读,是否继续阅读?

图拉扬科技有限公司为您提供《食醋中VOCs检测方案(自动进样器)》,该方案主要用于食醋中理化分析检测,参考标准--,《食醋中VOCs检测方案(自动进样器)》用到的仪器有HT2800T顶空多功能一体化自动进样器

相关方案

更多

该厂商其他方案

更多