仪器原理: 颗粒图象分析仪

分散方式: 干湿法分散

产地类别: 进口

重现性: <1%

测量范围: 5-3500微米

分辨率: 1微米

测量时间: 10-15秒

看了激光粒度仪的用户又看了

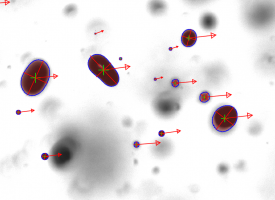

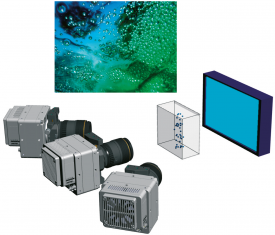

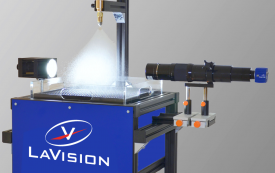

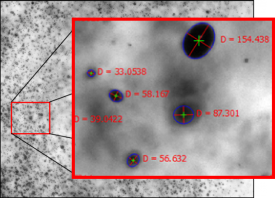

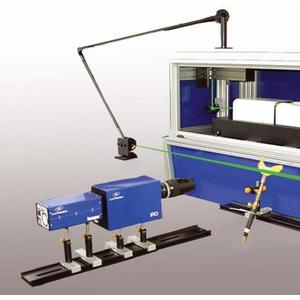

High resolution imaging and special backlight illumination are the key components of the ParticleMaster Shadow system. As opposed to laser diffraction or interferometric methods shadowgraphy does not require transparent and spherical particles and, therefore, is a quite universal technique for comprehensive particle characterization.The ParticleMaster software package automatically identifies valid particles in an image series and calculates all particle properties with outstanding processing speed incl. statistical information in real-time.

Shadowgraphy can well be combined with other flow imaging methods like PIV or thermometry for use in multiphase flows.

Our ParticleMaster 3D Shadow systems are based on tomographic shadow imaging. Using multiple shadow projections the tomographic reconstruction module in DaVis calculates the position and shape of particles, bubbles and droplets in 3D space. With time-resolved recordings particle trajectories with velocity and acceleration data are measured.

Time-resolved tomographic shadow imaging was successfully applied in bubbly flows for 3D flow imaging of both phases.

simultaneous size, position and shape

particle number density (corrected for different size classes)

particle velocity derived from double frame exposures

velocity - size correlations, histograms, scatterplots

mass flux

visualization of ligaments, spray break-up and atomization

保修期: 1年

是否可延长保修期: 是

现场技术咨询: 有

免费培训: 一人次

免费仪器保养: 质保期内一次

保内维修承诺: 全天候电话邮件微信远程连接支援服务

报修承诺: 一周内到达用户现场开始维修

激光诱导白炽光烟雾粒子成像分析仪(LII)

型号:SootMaster 50万 - 100万

汽车发动机多参量测试系统

型号:EngineMaster 面议

LaVision ParticleMaster-IMI 干涉米氏粒径测量

型号:ParticleMaster-IMI 80万 - 100万

美国Artium TK系列即插即用型颗粒粒径速度测量仪

型号:PDI-TK 40万 - 50万DaVis是德国LaVsion公司推出的应用于反应和非反应流场测量,材料表面成像和追迹以及超快成像的智能(激光)成像技术的完整软件平台。 DaVis以灵活的图像采集模块,可用户定制的应用界面和特殊应用软件包三大特色功能成就了完美的成像系统所需软件。 DaVis软件可满足用户以纳秒量级的精度进行相机曝光,外部照明以及外部触发的同步控制并能自由选择采集图像序列。除此之外,DaVis软件拥有各种成像设置和控制的功能。 DaVis软件对用户开放,这种特色结合软件本身的宏命令语言,能够使得成像系统快速适应从高深的科学研究到可靠的工业应用等各种不同测量需求。 不仅如此,DaVis还拥有灵活的图像采集模式,先进的图像处理算法,多维图像数据的智能存储和显示,多种硬件的软件控制等功能。 集成了2DPIV和3DPIV功能模块的DaVis软件,参加了连续三年的PIVChallenge(http://www.pivchallenge.org)评测活动,均取得了优异成绩。客观证明了DaVis软件平台的出色性能。 PIVChallenge的组织者将两次PIVChallenge 活动的结果作了详尽的总结,并将结果发表在了公开的网站和杂志上。有关文章和下载网址如下: 1. Stanislas M, Okamoto K, Kaehler C (2003) Main results of the First International PIV Challenge. Meas Sci Technol 14:R63-R89 下载地址: http://stacks.iop.org/0957-0233/14/R63 或: http://www.oplanchina.com/download/Stanislas PIV challenge 2001.pdf 2. Stanislas M, Okamoto K, Kaehler C, Westerweel J (2005) Main results of the Second International PIV Challenge. Exp Fluids 39: 170-191 下载地址:http://www.oplanchina.com/download/PIV Challenge 2003 Results.pdf

LaVision GmbH激光粒度仪SizingMaster-Shadow的工作原理介绍

激光粒度仪SizingMaster-Shadow的使用方法?

LaVision GmbHSizingMaster-Shadow多少钱一台?

激光粒度仪SizingMaster-Shadow可以检测什么?

激光粒度仪SizingMaster-Shadow使用的注意事项?

LaVision GmbHSizingMaster-Shadow的说明书有吗?

LaVision GmbH激光粒度仪SizingMaster-Shadow的操作规程有吗?

LaVision GmbH激光粒度仪SizingMaster-Shadow报价含票含运吗?

LaVision GmbHSizingMaster-Shadow有现货吗?

马尔文帕纳科激光粒度仪Mastersizer 3000

马尔文帕纳科激光粒度仪Mastersizer 3000+

HORIBA SZ-100 V2 纳米颗粒分析仪

麦奇克激光粒度仪 S3500系列

布鲁克海文高灵敏度Zeta电位及粒度分析仪90Plus PALS

最多添加5台