方案详情

文

■ 单内标校正,极大的简化了定量分析,无基体影响;

■ 对于任何基体的样品可单独进行校准和定量分析;

■ 多元素实时分析,可进行痕量和超痕量分析;

■ 不受样品的类型和不同应用需求影响;

■ 独特的液体或固体样品的微量分析,分析所需样品量小;

■ 优秀的检出限水平,元素分析范围从钠覆盖到铀;

■ 出色的动态线性范围;

■ 无需任何化学前处理,无记忆效应;

■ 非破坏性分析,运行成本低廉。

方案详情

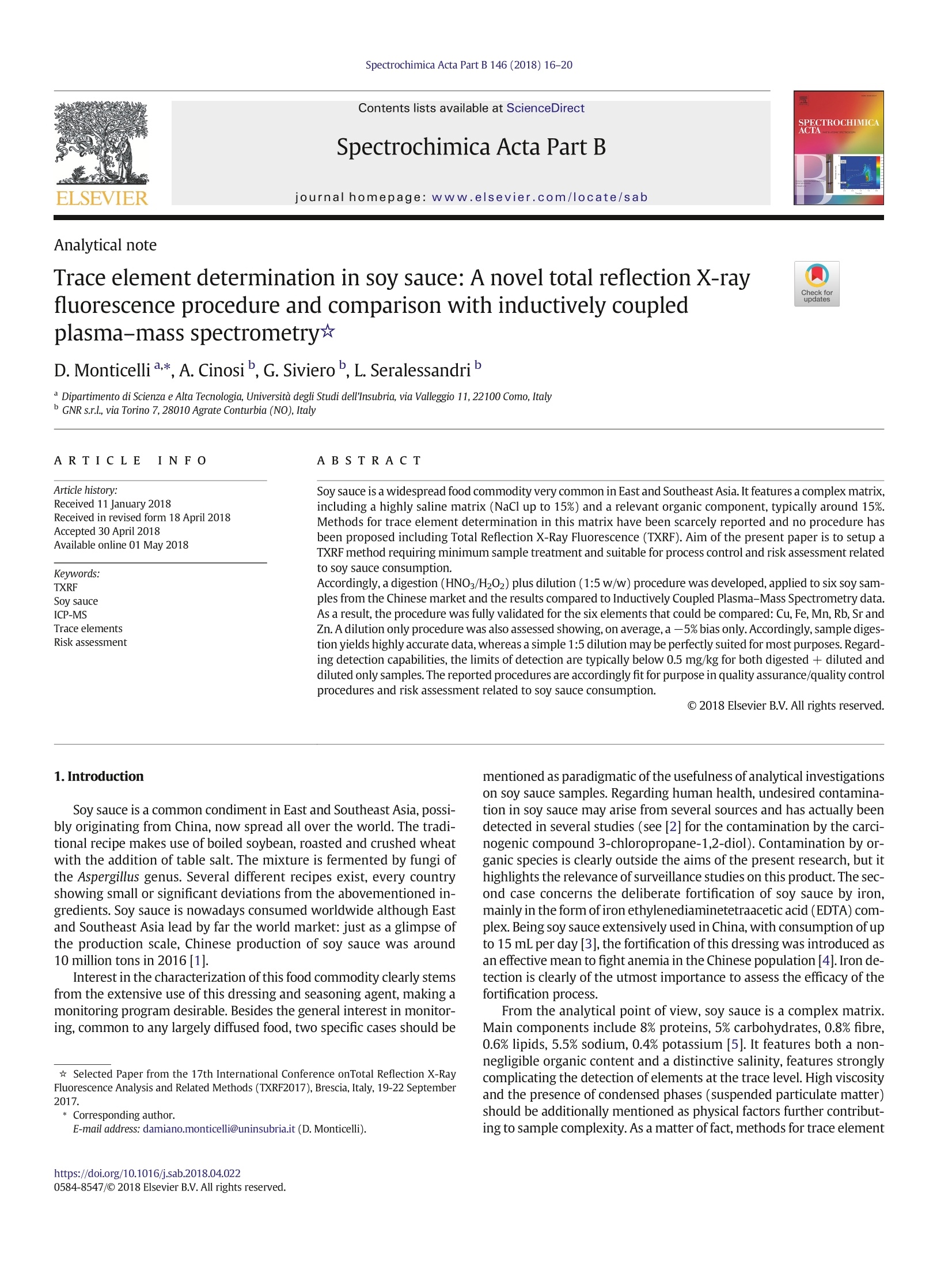

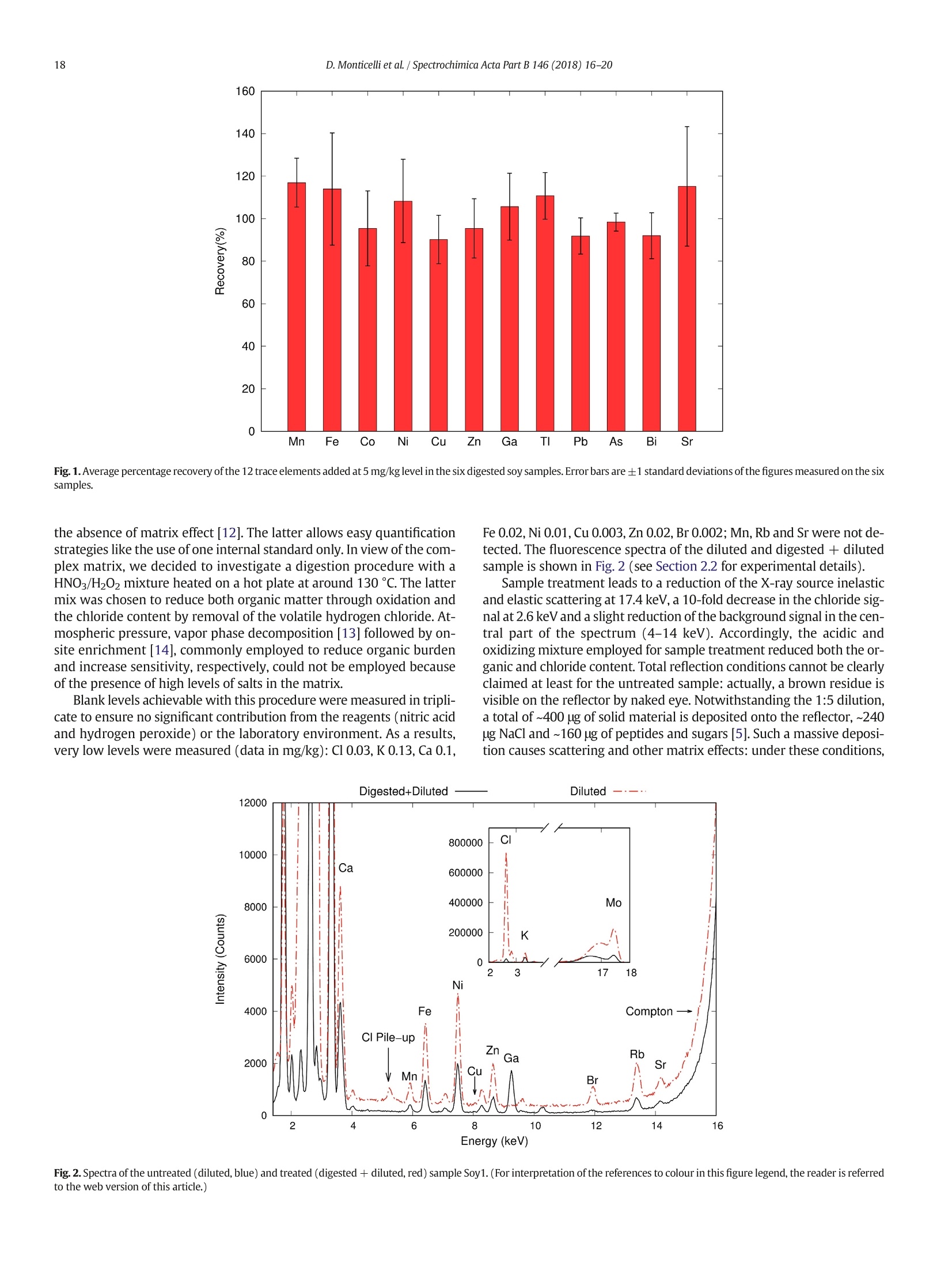

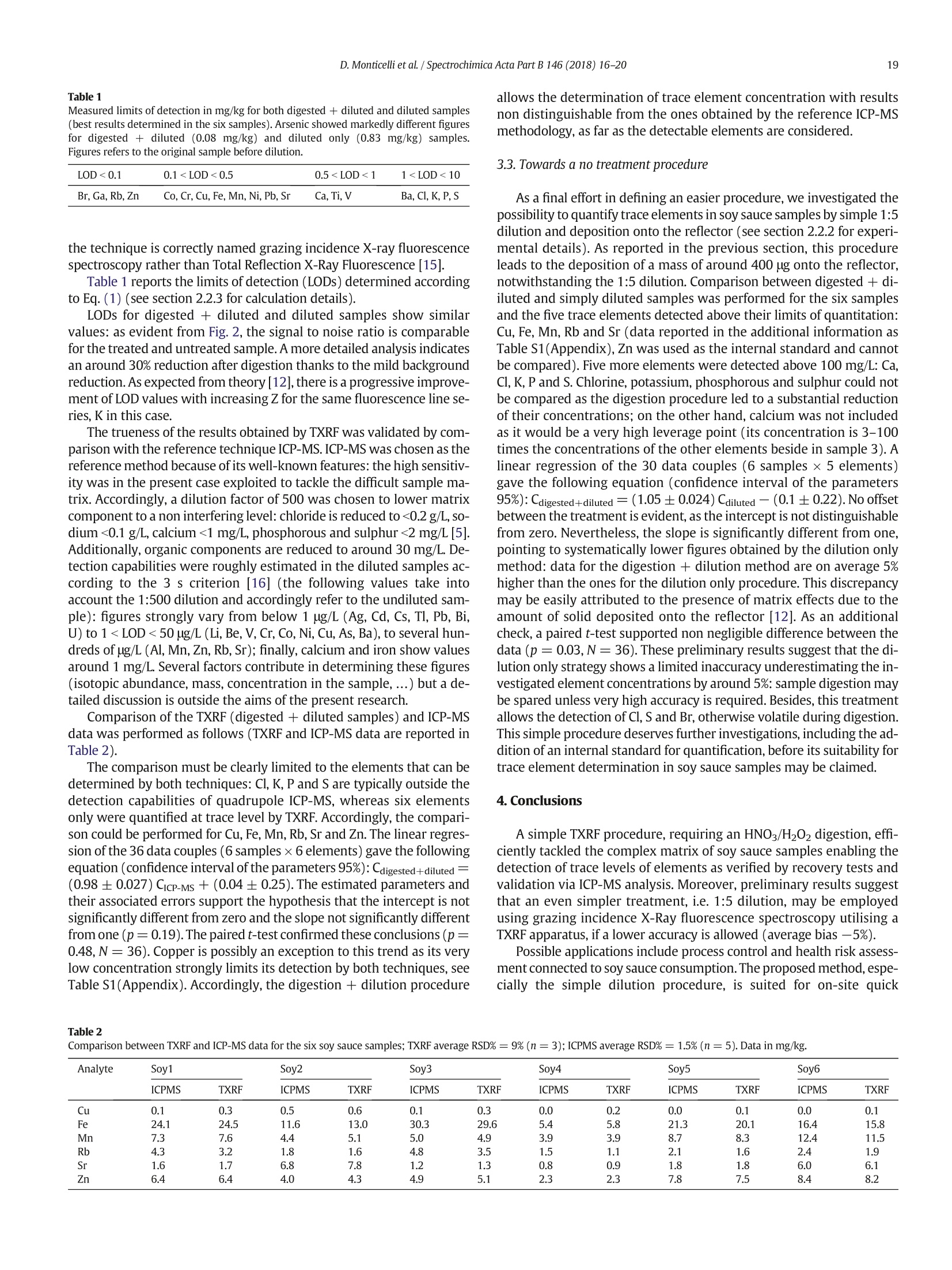

Spectrochimica Acta Part B 146 (2018)16-20Contents lists available at ScienceDirectjournalhomepage: www.elsevier.com/locate/sab 17D. Monticelli et al. / Spectrochimica Acta Part B 146 (2018) 16-20 Spectrochimica Acta Part B Analytical note Trace element determination in soy sauce: A novel total reflection X-rayfluorescence procedure and comparison with inductively coupledplasma-mass spectrometry* D. Monticelli a* A. Cinosi, G. SivierobL. Seralessandrib Dipartimento di Scienza e Alta Tecnologia, Universita degli Studi dell'Insubria, via Valleggio 11, 22100 Como, Italy” GNR s.r.l., via Torino 7, 28010 Agrate Conturbia (NO), Italy ARTICLE INFO ABSTRACT Article history:Received 11 January 2018Received in revised form 18 April 2018Accepted 30 April 2018Available online 01 May 2018 Soy sauce is a widespread food commodity very common in East and Southeast Asia. It features a complex matrix,including a highly saline matrix (NaCl up to 15%) and a relevant organic component, typically around 15%.Methods for trace element determination in this matrix have been scarcely reported and no procedure hasbeen proposed including Total Reflection X-Ray Fluorescence (TXRF). Aim of the present paper is to setup aTXRF method requiring minimum sample treatment and suitable for process control and risk assessment relatedto soy sauce consumption. Keywords: TXRFSoy sauceICP-MS Trace elements Risk assessment Accordingly, a digestion (HNO3/H202) plus dilution (1:5 w/w) procedure was developed, applied to six soy sam-ples from the Chinese market and the results compared to Inductively Coupled Plasma-Mass Spectrometry data.As a result, the procedure was fully validated for the six elements that could be compared: Cu, Fe, Mn, Rb, Sr andZn. A dilution only procedure was also assessed showing, on average,a -5%bias only. Accordingly,sample diges-tion yields highly accurate data, whereas a simple 1:5 dilution may be perfectly suited for most purposes. Regard-ing detection capabilities, the limits of detection are typically below 0.5 mg/kg for both digested + diluted anddiluted only samples. The reported procedures are accordingly fit for purpose in quality assurance/quality controlprocedures and risk assessment related to soy sauce consumption. 1. Introduction Soy sauce is a common condiment in East and Southeast Asia, possi-bly originating from China, now spread all over the world. The tradi-tional recipe makes use of boiled soybean, roasted and crushed wheatwith the addition of table salt. The mixture is fermented by fungi ofthe Aspergillus genus. Several different recipes exist, every countryshowing small or significant deviations from the abovementioned in-gredients.Soy sauce is nowadays consumed worldwide although Eastand Southeast Asia lead by far the world market: just as a glimpse ofthe production scale, Chinese production of soy sauce was around10 million tons in 2016 [1]. Interest in the characterization of this food commodity clearly stemsfrom the extensive use of this dressing and seasoning agent, making amonitoring program desirable. Besides the general interest in monitor-ing, common to any largely diffused food, two specific cases should be ( ☆ Selected Paper from t h e 17th International Conference onTotal R eflection X-Ray Fluorescence Analysis and Related Methods ( TXRF2017), Brescia, Italy , 19-22 September 2017. ) ( * C orresponding author. ) ( E-mail address: d am i a n o . mon ti c el l i@u n in su br i a . it (D. Monticelli). ) mentioned as paradigmatic of the usefulness of analytical investigationson soy sauce samples. Regarding human health, undesired contamina-tion in soy sauce may arise from several sources and has actually beendetected in several studies (see [2] for the contamination by the carci-nogenic compound 3-chloropropane-1,2-diol). Contamination by or-ganic species is clearly outside the aims of the present research, but ithighlights the relevance of surveillance studies on this product. The sec-ond case concerns the deliberate fortification of soy sauce by iron,mainly in the form ofiron ethylenediaminetetraacetic acid (EDTA) com-plex. Being soy sauce extensively used in China, with consumption ofupto 15 mL per day [3], the fortification of this dressing was introduced asan effective mean to fight anemia in the Chinese population [4]. Iron de-tection is clearly of the utmost importance to assess the efficacy of thefortification process. From the analytical point of view, soy sauce is a complex matrix.Main components include 8% proteins, 5% carbohydrates,0.8% fibre,0.6% lipids, 5.5% sodium, 0.4% potassium [5]. It features both a non-negligible organic content and a distinctive salinity, features stronglycomplicating the detection of elements at the trace level. High viscosityand the presence of condensed phases (suspended particulate matter)should be additionally mentioned as physical factors further contribut-ing to sample complexity. As a matter of fact, methods for trace element detection in soy sauce have been scarcely reported up to date (see e.g.[6] for an Inductively Coupled Plasma-Optical Emission Spectroscopydetermination); moreover, as evidenced in a recent review [7] devotedto food analysis by Total Reflection X-Ray Fluorescence (TXRF), no ap-plication of this technique to soy sauce samples has been reported inthe literature. Aim of the present research is to assess the possibilities of TXRF toprovide a rapid and reliable method for trace element determinationin this important food commodity. Data on trace element concentra-tions in several commercially available soy sauce samples were deter-mined and compared with results obtained by Inductively CoupledPlasma-Mass Spectrometry (ICP-MS). The fitness for purpose of theTXRF procedure will be discussed. 2. Materials and methods 2.1. Samples Six different soy sauce were obtained from the Chinese market fromsix different producers and labelled soy1 to soy6. Samples differed inviscosity, composition (markedly salinity) and, possibly, productionprocess (acidic hydrolysis vs. fungi fermentation). 2.2. TXRF procedures In order to remove the organic fraction and to limit the mass depos-ited on the quartz reflector, a digestion in nitric acid and hydrogen per-oxide followed by dilution was performed. One gram of each samplewas transferred in a 30 mL Savillex perfluoroalkoxy alkane vial with ascrew cap: gallium from a standard solution (Merck Gallium ICP stan-dard in HNO: 3%, 1000 mg/L) was spiked to have a concentration of10 mg/kg in the final solution after dilution and used as the internalstandard. Before closing the cap, 1.5 mL of HNO3 (Merck pro analysis65%) and 0.5 mL of H202 (Carlo Erba pure stabilized 40%) were added.After homogenization, digestion was performed by placing the vial ona hot plate at around 130 °℃ for 1 h. Finally, 1:5 dilution was achievedby adding ultrapure water (Carlo Erba Analytical Grade s0.1 uS/cm).The same procedure was performed in triplicate without adding anysample to assess the blank levels. The accuracy of the above procedure was evaluated with a recoverytest by adding 5 mg/L of a Merck ICP multi-element standard solution Ⅳin 6% nitric acid, 1000 mg/L in Ag, Al, B, Ba, Bi, Ca, Cd, Co, Cr, Cu, Fe, Ga, In,K, Li, Mg, Mn, Na, Ni, Pb, Sr, Tl, Zn at. The same concentration for As wasadded separately from an arsenic ICP standard solution (Merck in 3% ni-tric acid,1000 mg/L). Besides digestion, a 1:5 dilution only with ultrapure water wasattempted in order to investigate a possible fast way of quantifying ele-ments of interest without any treatment, which may alter the samplecomposition. Instead of adding gallium, zinc was used as internal stan-dard with a nominal concentration resulting from the correspondingdigested samples. For all the sample preparations described above, 8 ul were pipettedonto a siliconized (Serva Silicone Solution) quartz reflector, before dry-ing at 90 °C on a hot plate. Three different reflectors were prepared foreach sample. 2.2.1. Data acquisition and treatment Measurements were collected using a benchtop TXRF spectrometer(Horizon, G.N.R. Italy), equipped with a monochromatic X-ray source(Mo-Ko, 17.4 keV) at 40 kV, 15 mA and a 25 mm² Silicon Drift Detector.Counting time for each specimen was 300 s,after correction for detectordead time. Recorded spectra were analysed by the software supplied with theinstrument: after background and spectrum identification and fitting,quantification was achieved through the Internal Standard methodand relative sensitivity curves. The Limit of Detection (LOD) for the analyte x is calculated as threetimes the standard deviation of background signal area Nback below itsfluorescence peak of net area (intensity) Nx, according to Eq. (1)[8]: where cy is the analyte concentration (mass fraction). The ratio betweenNx and cx is the Sensitivity factor. 2.3. ICP-MS procedure Trace metals were determined by ICP-MS in the same samples by aniCAPQ instrument from Thermo Elemental. The latter was operated inthe kinetic energy discrimination mode to enable iron detection onthe 56 m/z channel: polyatomic interferences were reduced by intro-ducing a 4.84 mL/min flux of helium in the collision cell. Further optimi-zation of the instrumental parameters was performed to achieve bestsensitivity, low levels of oxides (CeO+/Ce+<2%) and of double chargedions (Ba++/Ba+<3%). Mass calibration was regularly verified. Major in-strumental parameters are as follows: plasma power 1.55 kW; gasflows: nebulizer 0.99 L/min, cool 14 L/min and auxiliary 0.8 L/min. Man-ufacturer suggested channels were acquired with a dwell time of 10 msfor element determination: five replicates per sample were measured(150 sweeps per replicate). Samples were simply diluted 1:500 (w/w)prior to analysis, adding concentrated pure nitric acid to a final concen-tration of 2% (pure HNOs was produced by a sub-boiling MilestoneDuoPur apparatus). External linear calibration was used for analytequantification in the range 0.1-75 pg/kg: standard solutions were ob-tained by diluting a Merck ICP multi-element standard VI. 3. Results and discussion The assessment of the capabilities of TXRF to investigate this matrixfollowed two different paths. As a first consideration, no standard refer-ence material exists for trace elements in soy sauce: validation strate-gies had to be adapted to this fact. Firstly, a recovery test wasperformed aiming at establishing the detection capabilities on a largenumber ofelements, contained or not in the original samples. In the fol-lowing Section 3.2, the concentrations of elements obtained after diges-tion with a HNO3/H202 mixture were compared, whenever possible, tothe ones obtained by the reference technique ICP-MS. Finally, a simple1:5 dilution with no other added reagents was checked and the resultscompared to the ones obtained by the digestion+dilution procedure. 3.1. Recovery test The recovery R for an analyte x of interest is given by Eq. (2)[9]: where cx is the concentration of the analyte in the sample after spiking,cx,o its concentration before spiking and Cx,spike the known addedquantity. Element recoveries were measured on all of the six digested soysamples and are reported in Fig. 1. The recovery values are in the range 90%-110%. These figures arethus in compliance with the 80%-110% range set by Codex AlimentariusCommission ProceduralManual for the concentrationi range1-10 mg/kg [10]. 3.2. Sample treatment and validation by comparison with ICP-MS data Sample treatment in TXRF is no less important than for any other an-alytical technique [11]. Specific to this technique is the well-known con-cept of critical thickness and critical mass, i.e. the sample physicalconditions that warrant thin film approximation which translates into D. Monticelli et al. / Spectrochimica Acta Part B 146 (2018) 16-20 the absence of matrix effect [12]. The latter allows easy quantificationstrategies like the use of one internal standard only. In view of the com-plex matrix, we decided to investigate a digestion procedure with aHNO3/H202 mixture heated on a hot plate at around 130C. The lattermix was chosen to reduce both organic matter through oxidation andthe chloride content by removal of the volatile hydrogen chloride. At-mospheric pressure, vapor phase decomposition [13] followed by on-site enrichment [14], commonly employed to reduce organic burdenand increase sensitivity, respectively, could not be employed becauseof the presence of high levels of salts in the matrix. Blank levels achievable with this procedure were measured in tripli-cate to ensure no significant contribution from the reagents (nitric acidand hydrogen peroxide) or the laboratory environment. As a results,very low levels were measured (data in mg/kg): Cl 0.03, K 0.13, Ca 0.1, Fe 0.02, Ni 0.01, Cu 0.003, Zn 0.02,Br 0.002;Mn, Rb and Sr were not de-tected. The fluorescence spectra of the diluted and digested + dilutedsample is shown in Fig. 2 (see Section 2.2 for experimental details). Sample treatment leads to a reduction of the X-ray source inelasticand elastic scattering at 17.4 keV, a 10-fold decrease in the chloride sig-nal at 2.6 keV and a slight reduction of the background signal in the cen-tral part of the spectrum (4-14 keV). Accordingly, the acidic andoxidizing mixture employed for sample treatment reduced both the or-ganic and chloride content. Total reflection conditions cannot be clearlyclaimed at least for the untreated sample: actually, a brown residue isvisible on the reflector by naked eye. Notwithstanding the 1:5 dilution,a total of ~400 pg of solid material is deposited onto the reflector,~240ug NaCl and~160 ug of peptides and sugars [5]. Such a massive deposi-tion causes scattering and other matrix effects: under these conditions, Energy (keV) Measured limits of detection in mg/kg for both digested + diluted and diluted samples(best results determined in the six samples). Arsenic showed markedly different figuresfor digested + diluted (0.08 mg/kg) and diluted only (0.83 mg/kg) samples.Figures refers to the original sample before dilution. LOD <0.1 0.1< LOD < 0.5 0.5

确定

还剩3页未读,是否继续阅读?

利曼中国为您提供《酱油中Cu/Fe/Mn/Rb/Sr/Zn等元素检测方案(能散型XRF)》,该方案主要用于酱油中营养成分检测,参考标准--,《酱油中Cu/Fe/Mn/Rb/Sr/Zn等元素检测方案(能散型XRF)》用到的仪器有HORIZON 全反射X荧光光谱仪

该厂商其他方案

更多